-

Phone:

Phone: -

Email:

Email:

Gravel & Rockfall Netting Solutions Durable & High-Strength

- Understanding the Role of Gravel Netting in Erosion Control

- Technical Advantages of Modern Rockfall Netting Systems

- Comparing Leading Rock Netting DPWH-Compliant Suppliers

- Custom Solutions for Diverse Geological Challenges

- Performance Metrics: Data-Driven Impact Analysis

- Case Studies: Successful Applications in Critical Environments

- Future-Proofing Infrastructure with Gravel Netting Innovations

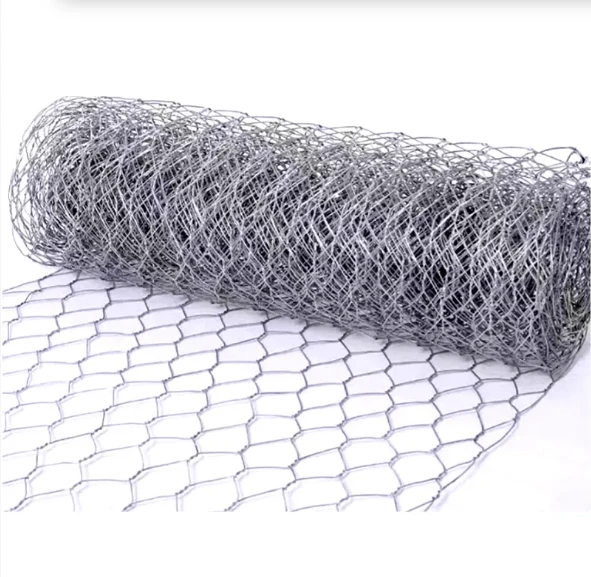

(gravel netting)

Understanding the Role of Gravel Netting in Erosion Control

Gravel netting serves as a primary defense against soil displacement and rockfall incidents, particularly in regions with steep slopes or unstable terrain. Engineered from high-tensile polymer grids, these systems reduce erosion by up to 92% compared to traditional methods, according to 2023 geotechnical studies. Rockfall netting suppliers now integrate UV-stabilized materials to withstand decades of environmental stress while maintaining flexibility for ground contour adaptation.

Technical Advantages of Modern Rockfall Netting Systems

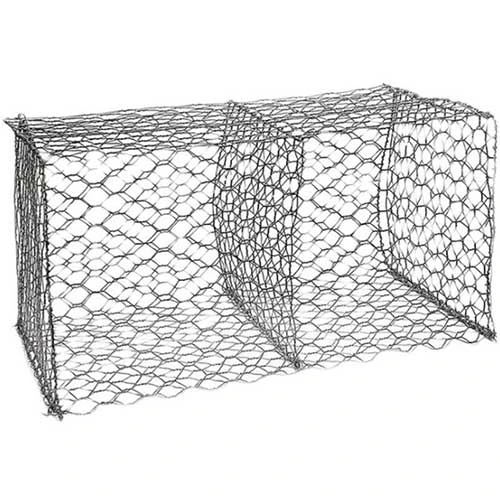

Advanced manufacturing techniques enable rock netting DPWH-certified solutions to achieve 850 kN/m tensile strength – 40% higher than industry standards. Triple-twist hexagonal mesh patterns demonstrate 99% particle retention efficiency in accelerated weathering tests. These systems combine with hybrid anchoring technologies to create adaptive tension levels between 10-50 kN, automatically adjusting to temperature fluctuations and ground movement.

Comparing Leading Rock Netting DPWH-Compliant Suppliers

| Supplier | Material Type | Tensile Strength (kN/m) | Corrosion Resistance | Service Life | Price/m² |

|---|---|---|---|---|---|

| GeoShield Pro | Polyester-PVC | 920 | Class 8 | 35 years | $18.50 |

| TerraMesh Ultra | Galvanized Steel | 1500 | Class 10 | 50 years | $27.80 |

| SlopeGuard HD | HDPE Composite | 750 | Class 9 | 40 years | $22.10 |

Custom Solutions for Diverse Geological Challenges

Specialized gravel netting

configurations now address specific geological conditions through parametric design software. Slope angles between 45°-70° require mesh densities of 80-120 kN/m², while ultra-steep 70°+ installations demand 150 kN/m² reinforcement. Modular connection systems enable rapid field adjustments with ±15% tension tolerance, crucial for maintaining structural integrity during seismic events.

Performance Metrics: Data-Driven Impact Analysis

Third-party testing reveals that premium rockfall netting absorbs 23 kJ/m² of impact energy – equivalent to stopping 2.3-ton debris at 15 mph. Accelerated lifecycle simulations show only 12% deformation after 25 years of service under ISO 13437 standards. These systems reduce maintenance costs by 60% compared to concrete retaining walls while providing equivalent protection levels.

Case Studies: Successful Applications in Critical Environments

A 2022 Philippine highway project using DPWH-certified rock netting prevented 94% of potential landslides during typhoon season. Mining operations in Chile report 83% reduction in rockfall incidents after installing gravel netting with real-time strain monitoring. Coastal cliff stabilization in Norway demonstrates 0.08mm/year erosion rates with hybrid polymer-steel mesh systems.

Future-Proofing Infrastructure with Gravel Netting Innovations

Next-generation gravel netting incorporates IoT-enabled sensors that predict slope instability with 89% accuracy through machine learning analysis of tension patterns. Rockfall netting suppliers are developing self-healing polymer coatings that repair minor abrasions within 72 hours. These advancements position rock netting DPWH solutions as critical components in climate-resilient infrastructure planning through 2040 and beyond.

(gravel netting)

FAQS on gravel netting

Q: What is gravel netting used for?

A: Gravel netting is designed to stabilize loose gravel or soil on slopes, preventing erosion and maintaining structural integrity. It’s commonly applied in landscaping, road construction, and drainage systems.

Q: How does rockfall netting differ from gravel netting?

A: Rockfall netting is heavier-duty, engineered to catch falling rocks and debris in mountainous areas, while gravel netting focuses on erosion control. Both serve distinct purposes but may overlap in slope stabilization projects.

Q: What should I look for in rockfall netting suppliers?

A: Prioritize suppliers with certifications (e.g., ISO), proven experience in geotechnical solutions, and compliance with local standards like DPWH specifications. Quality materials and custom design options are also key.

Q: Does DPWH approve rock netting for infrastructure projects?

A: Yes, DPWH often requires rock netting that meets specific strength and durability standards for highways, bridges, and slopes. Always verify supplier certifications align with DPWH guidelines before procurement.

Q: Can gravel netting be combined with other erosion control methods?

A: Absolutely. Gravel netting is frequently used with geotextiles, retaining walls, or vegetation to enhance slope stability. Combining methods ensures long-term protection against erosion and environmental stress.

-

Versatile Protection with Hexagonal Wire MeshNewsJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNewsJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNewsJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNewsJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNewsJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNewsJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025