-

هاتف:

هاتف: -

بريد إلكتروني:

بريد إلكتروني:

Strong by Nature: The Enduring Value of Hexagonal Wire Mesh

In the world of protective fencing and geotechnical engineering, no product blends strength, adaptability, and economy quite like hexagonal wire mesh. Whether used in flood control, slope stabilization, animal enclosures, or landscaping, this iconic mesh form has become a global go-to solution. And with enhancements like PVC coating, double twisting, and precision weaving, today’s hexagonal wire mesh manufacturers are delivering unmatched resilience for the most demanding projects.

What Makes It Unique: Materials Behind Hexagonal Wire Mesh

The foundation of every durable hexagonal wire mesh system lies in its raw materials. We offer meshes made from high-quality low-carbon steel, stainless steel, and galvanized steel wire—each chosen for specific environmental or structural applications.

Galvanized options resist rust and corrosion, making them ideal for outdoor use in wet or coastal climates. For even greater weatherproofing and chemical resistance, our pvc coated hexagonal wire mesh takes it a step further. The PVC layer not only shields the wire from abrasion and oxidation but also adds flexibility, UV resistance, and a more attractive appearance in green or black finishes.

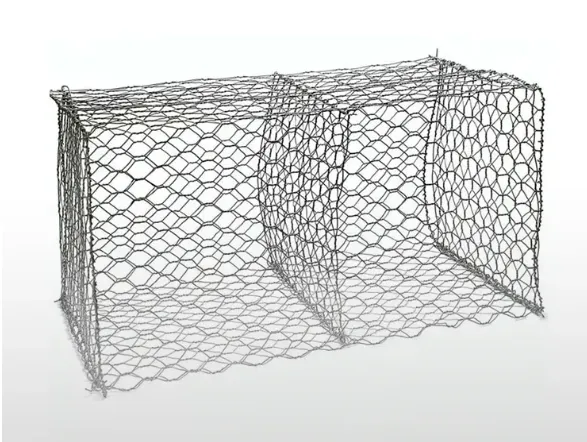

For projects demanding enhanced structural strength, double twisted hexagonal wire mesh provides superior tension distribution and prevents unraveling even under heavy stress. This makes it an excellent fit for retaining walls, riverbanks, and gabion applications where integrity under load is non-negotiable.

Form Meets Function: How Hexagonal Wire Mesh Is Woven

The signature hexagon pattern isn’t just about aesthetics—it’s an engineering advantage. Our hexagonal wire mesh is woven using automated machines that twist adjacent pairs of wires in alternating directions, forming a continuous series of six-sided cells.

This “double twist” technique allows the mesh to flex under pressure while maintaining its shape, an essential trait for dealing with shifting soils, river currents, or wildlife movement. Even if a single wire breaks, the surrounding mesh remains intact—preventing catastrophic failure.

This intricate weaving process is carefully monitored for wire diameter, mesh opening size, twist count, and uniformity, ensuring each roll meets both national and international industry standards. As trusted hexagonal wire mesh manufacturers, we take pride in every loop and twist.

Defending the Edge: Why Hexagonal Wire Mesh Is Ideal for Riverbank and Flood Control

In flood-prone areas and along unstable riverbanks, erosion control is a top priority. That’s where hexagonal wire mesh shines. Its flexible structure conforms to the natural contours of riverbeds and slopes, providing a stabilizing layer that prevents soil from washing away during high-flow events.

In flood control applications, hexagonal wire mesh is used to construct gabion baskets—wire containers filled with rock that are stacked to create permeable barriers. These structures absorb hydraulic energy, reduce water velocity, and protect the land from scouring and collapse.

Thanks to its rust-resistant coatings and load-bearing capabilities, our pvc coated hexagonal wire mesh offers a long-term solution for municipalities, civil engineering firms, and disaster response agencies working on river regulation and infrastructure protection.

Customized Performance: Versatile Applications and Pricing

From fencing and farm boundaries to military fortifications and architectural design, hexagonal wire mesh is as versatile as it is durable. We manufacture a wide range of mesh sizes and wire gauges to match your exact needs, and our materials meet ASTM, BS, DIN, and ISO standards.

As reliable hexagonal wire mesh manufacturers, we also offer tailored services including cut-to-length panels, colored PVC coatings, and reinforced edging. Whether you’re looking for lightweight mesh for garden use or heavy-duty solutions for embankments, we deliver on time and within budget.

And when it comes to cost, our hexagonal wire mesh price reflects unbeatable value. With bulk order discounts, fast logistics, and full customer support, we ensure that quality never breaks the bank.

Hexagonal Wire Mesh FAQs

What are the most common materials used in hexagonal wire mesh?

Our meshes are made from galvanized steel, low-carbon steel, stainless steel, and pvc coated hexagonal wire mesh options for extra durability and environmental resistance.

How is hexagonal wire mesh woven into a hexagon structure?

It uses a double-twist weaving method, where parallel wires are twisted in opposite directions to form strong, flexible six-sided openings.

Why is hexagonal wire mesh suitable for riverbank and flood control?

Its flexible design conforms to terrain, and when used in gabion structures, it reduces erosion, slows water flow, and supports long-term bank stability.

What is the advantage of double twisted hexagonal wire mesh?

The double twist enhances tensile strength and prevents mesh from unraveling even under extreme loads or damage, making it perfect for geotechnical applications.

How do you determine the hexagonal wire mesh price?

Hexagonal wire mesh price depends on wire material, coating type, mesh size, quantity, and whether customization is required. We provide competitive rates for every project size.

-

Versatile Protection with Hexagonal Wire MeshأخبارJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceأخبارJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingأخبارJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleأخبارJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireأخبارJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireأخبارJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingأخبارJun.09,2025