-

Phone:

Phone: -

Email:

Email:

wire coat hanger manufacturers

The Wire Coat Hanger Manufacturing Industry

In the world of garment care and organization, wire coat hangers have long been a staple. These simple yet effective objects provide a reliable solution for hanging clothes, helping them maintain their shape and reduce wrinkles. The manufacturing of wire coat hangers is an intricate process that involves various stages, from design to production, impacting not only the fashion industry but also home organization solutions.

The Manufacturing Process

The production of wire coat hangers begins with sourcing high-quality materials, typically steel wire. Manufacturers often choose galvanized or stainless steel due to their durability and corrosion resistance. After procuring the raw materials, the wire is cut into specific lengths based on hanger designs. The wire is then shaped using specialized machinery.

The shaping process can vary significantly depending on the style of the hanger. For instance, basic hangers might only require a simple hook and shoulder formation, while specialty hangers, designed for specific garments like pants or skirts, necessitate additional features. Advanced manufacturers use automated machinery for precision shaping, which increases efficiency and reduces production costs.

Design and Customization

Wire coat hangers are not just utilitarian; they can also be designed to suit various styles and needs. Many manufacturers offer customization options, allowing businesses or individuals to create hangers that reflect their brand or personal style. Custom colors, branding options, and additional features such as notches for straps or padded areas for delicate fabrics are increasingly popular.

Eco-friendly options are also gaining traction in the market. Manufacturers are exploring sustainable practices by using recycled materials and providing hangers that are entirely biodegradable. These practices not only appeal to environmentally conscious consumers but also help companies adhere to increasing regulatory standards aimed at reducing waste.

wire coat hanger manufacturers

The Market Landscape

The wire coat hanger manufacturing industry is highly competitive, with numerous players ranging from small local workshops to large multinational corporations. The global demand for hangers is influenced by various factors including the growth of the apparel industry, e-commerce, and retail trends. With the rise of online shopping, the need for effective packaging solutions, including hangers that prevent garments from crumpling during transit, has become crucial.

Additionally, regions with a high concentration of garment manufacturing, such as Southeast Asia and Bangladesh, often have a robust network of wire coat hanger producers. These manufacturers benefit from proximity to their primary customers—clothing brands and retailers—enabling them to provide cost-effective logistical solutions.

Challenges and Innovations

Despite the stability of the wire coat hanger market, manufacturers face challenges. Fluctuations in raw material prices and the need for continuous innovation to meet changing consumer preferences are ongoing concerns. As fashion trends shift towards more sustainable and ethical practices, companies must adapt quickly.

Investments in technology have become essential for staying competitive. Innovations such as automated production lines and AI-driven quality control systems enhance efficiency and reduce waste. Moreover, manufacturers are exploring smart hanger designs that integrate technology to provide additional functionality, such as tracking garment care needs.

Conclusion

The wire coat hanger manufacturing industry plays a crucial role in the broader apparel ecosystem. By combining functionality, design, and sustainability, manufacturers are rising to the challenges of a competitive market, continually adapting to meet consumer needs. As the industry evolves, the humble wire coat hanger remains a critical tool in the quest for organized and wrinkle-free clothing, proving that even the simplest products can have a significant impact.

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025

-

The Smart Choice of Chain Link FenceNewsJun.09,2025

-

Securing the Future with Time-Tested Barbed Wire ProtectionNewsJun.09,2025

-

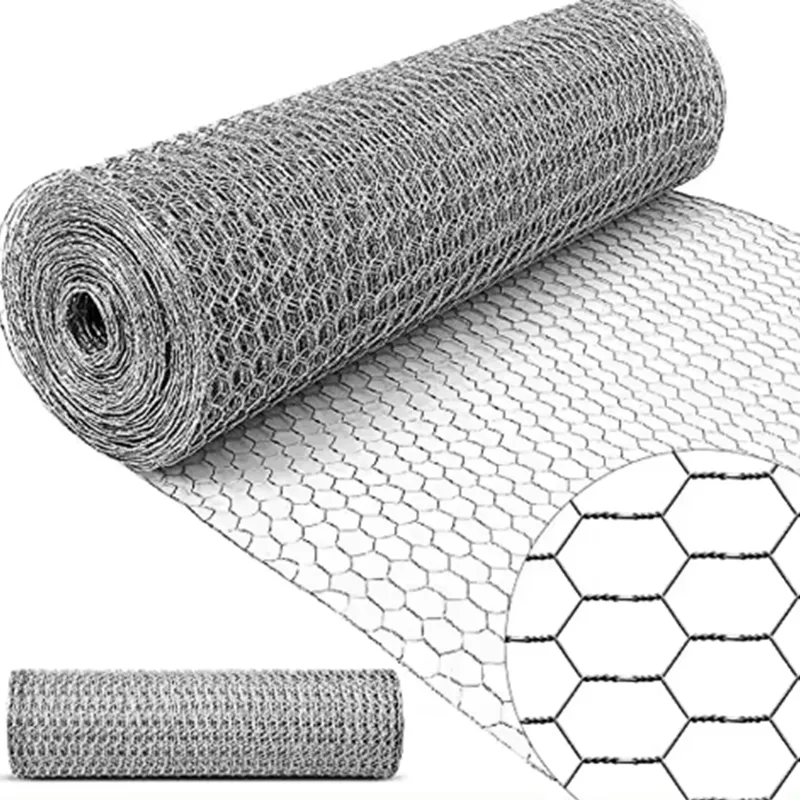

Reliable and All-Season Fencing with Premium Hexagonal Wire MeshNewsJun.09,2025

-

High-Performance Binding Solutions with Premium Loop Tie WireNewsJun.09,2025

-

Durable, Flexible, and High-Performance Baling Wire for SaleNewsJun.09,2025

-

Unveiling the Versatility of Hexagonal Wire MeshNewsMay.21,2025