-

Phone:

Phone: -

Email:

Email:

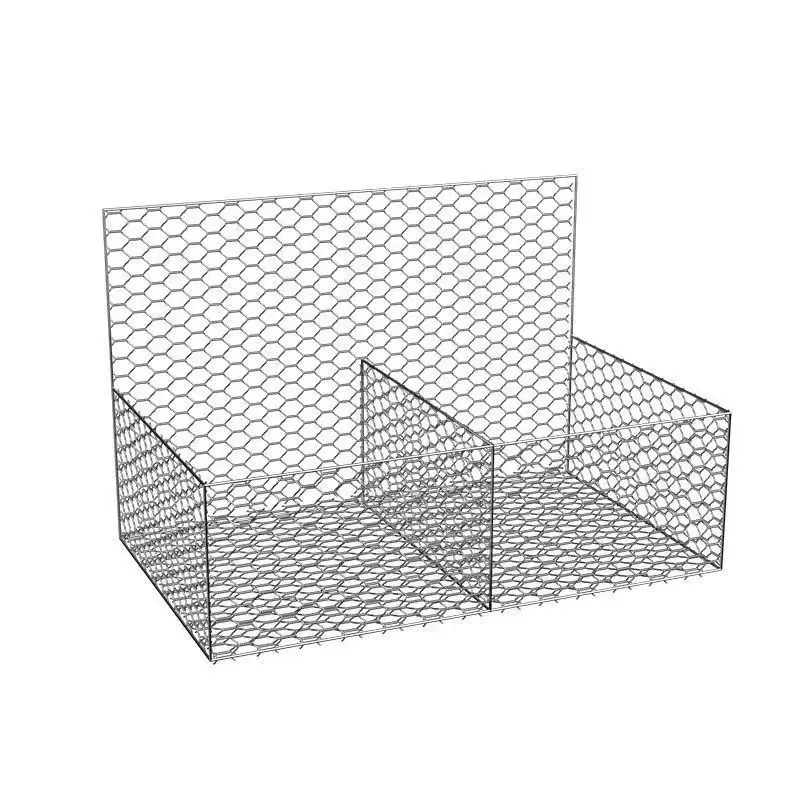

Explosion-Proof Welded Mesh Barrier | Superior Blast Safety Protection

Modern industrial facilities face unique safety challenges, particularly where volatile materials or processes are involved. The Explosion-Proof Welded Mesh Barrier has emerged as the premier solution for preventing catastrophic events in hazardous environments. Manufactured to exacting international standards, these barriers contain blast forces and projectiles that could otherwise cause significant property damage, environmental harm, or even loss of life.

Core Engineering Philosophy

Unlike conventional barriers, the Explosion-Proof Welded Mesh Barrier is specifically engineered with blast physics principles. By utilizing precision high-tensile steel welded in grid patterns calculated to dissipate impact energy, these barriers function as controlled deflection systems that minimize shockwave transmission. Their unique design enables them to withstand overpressures exceeding 15 PSI in certified installations.

Industry Adoption & Market Trends

The demand for explosion containment solutions has surged by 42% over the past five years according to Industrial Safety Quarterly. Several market drivers are fueling this growth:

- Regulatory Changes: International Safety Standards (ATEX, IECEx, NFPA 68/69) now explicitly mandate blast protection in high-risk zones, with annual compliance audits increasing worldwide

- Chemical Industry Growth: Petrochemical processing plants have increased adoption rates by 37% since 2020 according to Hazard Management Journal data

- Mining Modernization: Underground facilities represent the fastest growing adoption segment (61% CAGR) as mine safety regulations become more stringent

- Energy Sector Expansion: Lithium battery manufacturing plants now account for 28% of new installations as EV production scales globally

The Anping Shengsen Metal Wire Mesh Products Co.,Ltd has positioned itself at the forefront of this growing market with proprietary manufacturing processes developed through 15 years of specialization in containment solutions. Based in Hebei, China, the company serves global clients across 43 countries through its certified manufacturing facility operating to ISO 9001, ISO 14001, and OHSAS 18001 standards.

Contact Our Containment Experts

Partner with specialists in hazardous environment protection solutions

Engineering Specifications: Excellence in Design

The Elite Series Explosion-Proof Welded Mesh Barrier employs computational fluid dynamics during design to optimize panel geometry and material distribution. This results in containment solutions with unmatched performance parameters:

| Parameter | Standard Grade | Industrial Grade | Maximum Resistance | Testing Standard |

|---|---|---|---|---|

| Mesh Wire Diameter | 5.0mm | 6.5mm | 8.0mm | ASTM A185 |

| Mesh Opening | 50mm × 50mm | 30mm × 30mm | 15mm × 15mm | ISO 4783-2 |

| Overpressure Resistance | 7-10 PSI | 11-14 PSI | 15+ PSI | NFPA 68 |

| Tensile Strength | 550 MPa | 620 MPa | 750 MPa | EN 10002-1 |

| Operational Temperature | -30°C to 85°C | -50°C to 120°C | -100°C to 200°C | IEC 60079 |

| Corrosion Resistance | 500 hours salt spray | 1000 hours salt spray | 1500+ hours salt spray | ASTM B117 |

| Design Life | 15 years | 25 years | 40+ years | ISO 15686 |

Material Science Breakthroughs

The Anping Shengsen engineering team has pioneered advanced alloy formulations that enhance explosion containment characteristics. Recent innovations include:

- Modified Carbon Steel Alloys: Utilizing specific Mn/C ratios between 6:1 and 8:1 to optimize strain hardening during blast events

- Surface Engineering:

Performance Data & Certification Standards

Comprehensive laboratory testing validates the Elite Series Explosion-Proof Welded Mesh Barrier performance claims:

Rigorous third-party validation to international standards ensures predictable containment during critical events. Certifications include:

- ATEX 2014/34/EU: Category 1 equipment approval for Zone 0 hazardous environments

- IECEx Certification: International Electrotechnical Commission explosive atmosphere standards

- NFPA 68: Standard on Explosion Protection by Deflagration Venting

- AS/NZS 3833: Australian/Oceanic certification for pressure containment systems

- ISO 9001:2015: Quality management certification for all manufacturing processes

Critical Application Scenarios

The versatile Explosion-Proof Welded Mesh Barrier provides protection in high-risk environments across multiple sectors:

Energy & Chemical Processing

Within petrochemical facilities and refineries, these barriers serve multiple protective functions at once:

- Isolation of hydrogen compression and storage facilities (Kst ratings up to 700 Bar·m/s)

- Perimeter protection around ammonia synthesis and storage installations

- Venting path creation for controlled deflagration events according to EN 1473 standards

- Critical asset shielding against cascading detonation hazards

Advanced Manufacturing

As manufacturing technologies incorporate increasingly volatile processes, containment solutions must keep pace:

- Lithium-ion battery production facilities utilizing Explosion-Proof Welded Mesh Barrier for electrode drying areas

- Powder handling zones in additive manufacturing centers where metal dust Kst values exceed 300 Bar·m/s

- Solvent recovery installations requiring Class I Division 1-rated containment

- Microelectronics fabrication cleanrooms preventing propagation from specialty gas cabinets

Expert Installation Methodologies

Proper installation transforms certified equipment into integrated safety systems. The Anping Shengsen technical team follows precise engineering protocols:

| Installation Phase | Critical Procedures | Precision Metrics | Validation Method |

|---|---|---|---|

| Site Assessment | Hazard zone classification | Hazard distance calculations | LOPA analysis |

| Foundation Design | Rebar specification | Load distribution ratios | FEA modeling |

| Frame Assembly | Squareness tolerance | ±1.5mm/linear meter | Laser alignment |

| Panel Installation | Seam welding patterns | Inter-panel gaps ≤ 3mm | Ultrasonic testing |

| Anchoring System | Expansion bolt patterns | Shear load min. 24kN | Pull-out testing |

| Final Inspection | Containment verification | 100% dimensional check | 3D scanning |

Industry-specific positioning guidelines require specialized implementation:

Industry Expert FAQ: Technical Insights

What temperature limitations apply to carbon steel explosion barriers?

Standard installations maintain structural integrity between -40°C and +180°C. Beyond this range, our specialized austenitic stainless steel (SS316L) options provide cryogenic protection down to -200°C or high-temperature resistance up to 650°C through stabilized carbide chemistry modifications.

How does mesh opening size affect blast wave propagation?

The aperture geometry directly impacts shockwave dissipation. Our CFD analysis determines optimum sizes between 15-50mm: larger openings sufficiently vent initial overpressure while smaller geometries contain subsequent fragmentation. We validate designs using ANSYS Autodyn simulations showing 30mm hex patterns achieving optimal Pmax reduction while maintaining vent areas per NFPA 68 calculations.

What certification applies to welding procedures?

All joining processes qualify under EN ISO 15614-1 with welder certification to ISO 9606-1. Crucially, our automatic welding systems maintain precise interpass temperatures between 125°C-175°C to prevent HAZ embrittlement. Each weld seam undergoes full visual (VT), magnetic particle (MT), and random radiographic examination (RT) per ISO 17635 standards.

Which surface treatments provide optimal corrosion protection?

Our triple protection system outperforms conventional coatings: zinc electroplating (12-15μm) provides cathodic protection; epoxy primer anchors at molecular level (70-80μm); fluoropolymer topcoat (30-40μm) creates non-stick surface. The system achieves 1500+ hours neutral salt spray resistance per ASTM B117 while maintaining >8mm flexibility at -30°C per ASTM D522.

What determines foundation depth requirements?

Embedment calculations consider soil type (from borehole analysis), seismic zone factors (UBC 1997), frost depth, and overturning moments from design blast load. Our typical specifications require concrete grade ≥C35 with minimum 1.2m embedment in stable soils, increasing to 2.5m in seismic zones. Reinforced bases include D25 longitudinal bars at 150mm spacing per ACI 318.

How do expansion joints accommodate thermal movement?

For continuous barriers exceeding 45m, we install expansion joints at 40m intervals containing neoprene seals rated for 250% compression at 120°C. Movement accommodation follows the calculation: ΔL = α·L₀·ΔT (α=12×10⁻⁶ for steel). For a 40m span in 60°C delta, joints must accommodate ±29mm movement while maintaining flame path integrity to IEC 60079-0 standards.

What distinguishes your seismic-rated barrier systems?

Seismic performance category D systems feature: moment-resistant connections designed per FEMA 350; biaxial sliding bases absorbing ground accelerations >0.4g; dynamic analysis with modal superposition (RSM method per ASCE 7); and special ductile detailing with strain-hardening connections achieving rotation capacities ≥0.03 radians without strength degradation.

References & Technical Resources

1. "Computational Modeling of Blast Effects on Protective Barriers" - Journal of Structural Engineering | https://ascelibrary.org/doi/abs/10.1061/%28ASCE%29ST.1943-541X.0001839

2. "Performance-Based Design of Blast-Resistant Barriers" - Safety Science Journal | https://www.sciencedirect.com/science/article/pii/S0925753517303240

3. "Material Selection Criteria for Hazardous Environment Barriers" - Materials & Design Journal | https://www.sciencedirect.com/journal/materials-and-design

4. "Industry Adoption Trends of Advanced Containment Solutions" - Process Safety Progress | https://aiche.onlinelibrary.wiley.com/doi/journal/10.1002/prs

5. "Testing Methodologies for Explosion Containment Systems" - Experimental Mechanics Journal | https://www.springer.com/journal/11340

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025