-

Phone:

Phone: -

Email:

Email:

Hexagonal Wire Mesh Price: Quality Chicken Wire & Sizes

Navigating the Market: Understanding hexagonal wire mesh price

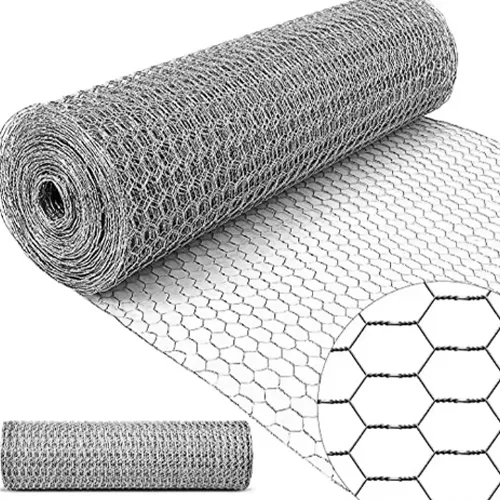

In the diverse landscape of industrial and construction materials, hexagonal wire mesh stands out for its versatility, durability, and cost-effectiveness. Often referred to as chicken wire or poultry netting, its unique twisted hexagonal pattern provides exceptional flexibility and strength, making it ideal for a wide range of applications from agricultural fencing to construction reinforcement. For B2B decision-makers and procurement specialists, understanding the factors that influence the hexagonal wire mesh price is crucial for strategic sourcing and optimizing project budgets. This comprehensive guide delves into the intricacies of hexagonal wire mesh, exploring its technical specifications, manufacturing processes, key applications, and the market dynamics that shape its cost, ensuring you make informed purchasing decisions.

The market for hexagonal wire mesh is influenced by various factors, including raw material costs, production technologies, and global supply-demand trends. Its adaptability to different environments and uses, from simple barriers to complex structural components, highlights its importance across multiple sectors. As industries evolve, the demand for high-quality, reliable, and economically viable mesh solutions continues to grow, emphasizing the need for a thorough understanding of product specifications and pricing structures. We aim to provide a detailed overview that enhances your comprehension of this vital product, ensuring value for your investment.

Unpacking Hexagonal Wire Mesh: Types and Technical Parameters

Hexagonal wire mesh is categorized primarily by its material, surface treatment, and physical dimensions. Common types include galvanized hexagonal wire mesh (electro-galvanized or hot-dip galvanized) and pvc coated hexagonal wire mesh, each offering distinct advantages in terms of corrosion resistance and longevity. Galvanization provides a protective zinc layer, while PVC coating adds an extra layer of defense against harsh environmental conditions, often in various colors for aesthetic or application-specific needs. The choice of material and coating significantly impacts the final hexagonal wire mesh price and its suitability for specific applications, ranging from general fencing to marine environments.

Key technical parameters define the mesh's performance and application suitability. These include wire gauge (thickness of the wire), mesh size (the opening of the hexagon), roll width, and roll length. Standard hexagonal wire mesh sizes vary widely to accommodate different requirements, from fine meshes for rodent control to larger openings for gabion baskets. Understanding these specifications is paramount for specifying the correct product for your project, ensuring optimal performance and cost-efficiency. For instance, a finer mesh might command a higher hexagonal wire mesh price per unit area due to increased material usage and production complexity.

Factors Influencing Hexagonal Wire Mesh Pricing

The hexagonal wire mesh price is a dynamic variable influenced by several critical factors. Raw material costs, primarily steel wire, fluctuate based on global commodity markets and can significantly impact the final product cost. The type of coating—whether standard electro-galvanized, heavy hot-dip galvanized, or PVC coated—adds varying levels of expense due to material cost and complexity of the coating process. For example, a heavy hot-dip galvanized mesh offers superior corrosion resistance and longer service life, justifying a higher initial hexagonal wire mesh price compared to a light galvanized option.

Production specifications such as wire gauge, mesh opening, and overall roll dimensions (width and length) also play a major role. Thicker wire gauges and smaller mesh openings require more raw material and longer manufacturing times, leading to a higher per-unit cost. Furthermore, order volume can provide economies of scale, often resulting in more favorable pricing for larger purchases. Geographic location, shipping costs, and the current market supply and demand dynamics further contribute to the variations in hexagonal wire mesh price across different suppliers and regions. Understanding these variables allows for more effective budget planning and negotiation.

Standard Specifications and Pricing Considerations

To facilitate a clearer understanding of the value proposition, here’s a table outlining common hexagonal wire mesh sizes and their typical applications, alongside factors that influence their specific pricing brackets. This data helps in estimating the hexagonal wire mesh price based on your project's technical needs and desired longevity.

| Mesh Opening (Inch/mm) | Wire Gauge (BWG/mm) | Coating Type | Typical Applications | Price Factor (Relative) |

|---|---|---|---|---|

| 1/2" (13mm) | 22 BWG (0.71mm) | Electro Galvanized | Small animal enclosures, plastering support | Medium |

| 1" (25mm) | 20 BWG (0.89mm) | Hot-Dip Galvanized | Hexagonal chicken wire mesh, garden fencing, small animal fencing | Medium-High |

| 1" (25mm) | 19 BWG (1.07mm) | PVC Coated | Decorative fencing, coastal area applications | High |

| 2" (50mm) | 16 BWG (1.65mm) | Hot-Dip Galvanized | Gabion baskets, light livestock containment | High |

| 3" (75mm) | 14 BWG (2.11mm) | Hot-Dip Galvanized | Heavy-duty gabions, erosion control | Very High |

Adherence to international standards like ISO 9001 for quality management and relevant ASTM or EN standards for material composition and coating thickness ensures product reliability and performance. Reputable manufacturers comply with these benchmarks, which, while potentially influencing the base hexagonal wire mesh price, guarantee a product that meets expected service life and durability requirements, reducing long-term costs associated with replacement or maintenance.

Applications and Technical Advantages

The distinctive hexagonal weave grants this mesh exceptional flexibility, allowing it to conform to irregular surfaces and absorb impacts without unraveling, making it highly advantageous in various applications. Common uses include agricultural fencing, such as hexagonal chicken wire mesh for poultry enclosures, where its small openings prevent escape and protect from predators. In construction, it serves as plastering mesh to reinforce walls, preventing cracks, and as insulation mesh to hold insulating materials in place. For civil engineering, heavier gauge hexagonal mesh is crucial for gabion baskets and mattresses, providing stable and permeable structures for retaining walls, erosion control, and river training works, often specified where a durable, flexible, and environmentally friendly solution is required.

The technical advantages of hexagonal wire mesh stem from its material properties and manufacturing process. Its inherent flexibility simplifies installation and reduces labor costs. When properly galvanized or PVC coated, it offers excellent corrosion resistance, ensuring a prolonged service life even in harsh outdoor environments, leading to a favorable long-term cost of ownership despite the initial hexagonal wire mesh price. Its structural integrity means it maintains shape and function under various stresses, providing reliable containment or reinforcement. The open mesh design allows for air and water passage, making it suitable for applications where drainage or ventilation is critical, such as gabion structures in water management projects.

The Manufacturing Process: Quality and Durability

The production of hexagonal wire mesh is a multi-stage process designed to ensure durability and consistent quality. It begins with high-quality steel wire, typically low-carbon steel, which undergoes a precise wire drawing process to achieve the desired wire gauge. This step is critical as it determines the tensile strength and overall integrity of the finished product. Following wire drawing, the wires are fed into specialized weaving machines that interlock them into the distinct hexagonal pattern. This twisting mechanism ensures that even if a wire breaks, the mesh retains its form, preventing unraveling and enhancing safety and longevity.

After weaving, the mesh undergoes surface treatment. For galvanized mesh, it can be electro-galvanized (for lighter zinc coating) or hot-dip galvanized (for heavier, more durable zinc coating). The hot-dip galvanization process involves immersing the mesh in molten zinc, creating a metallurgical bond that provides superior corrosion resistance, directly influencing the final hexagonal wire mesh price and performance. For pvc coated hexagonal wire mesh, a layer of PVC powder is applied and heat-fused over the galvanized mesh, adding another protective and often aesthetic layer. Throughout these stages, stringent quality control measures are implemented, adhering to standards like ISO 9001 and ASTM, to check wire diameter, mesh opening accuracy, coating thickness, and overall structural integrity. This meticulous process ensures a reliable product with an extended service life in diverse conditions, contributing to the overall value proposition beyond the immediate hexagonal wire mesh price.

Manufacturer Comparison and Custom Solutions

When evaluating suppliers for hexagonal wire mesh, it's essential to look beyond the initial hexagonal wire mesh price and consider factors such as manufacturing capabilities, quality assurance, and customer support. Reputable manufacturers will offer comprehensive technical data, provide certifications (e.g., ISO 9001), and have a proven track record of delivering consistent product quality. Comparing manufacturers involves assessing their capacity for customized solutions, as standard sizes or coatings may not always perfectly align with unique project requirements. A supplier capable of offering bespoke wire gauges, mesh sizes, or specific PVC colors can be invaluable for specialized applications, such as for the demanding specifications of a large-scale construction project or a precise agricultural solution.

At WireMeshPro, we leverage over two decades of experience in wire mesh manufacturing, offering not only a competitive hexagonal wire mesh price but also unparalleled product quality and customization options. Our state-of-the-art production facilities adhere to strict international quality standards, ensuring every roll of hexagonal wire mesh meets rigorous performance benchmarks. We collaborate closely with clients to develop tailor-made solutions, whether it involves specialized hexagonal wire mesh sizes, unique coating specifications, or large-volume orders. Our commitment to innovation and customer satisfaction ensures that you receive a product that perfectly aligns with your project's technical and budgetary requirements, providing long-term value and reliability.

Real-World Applications and Success Stories

Hexagonal wire mesh's versatility is best illustrated through its wide range of successful applications. In agricultural settings, a prominent poultry farm significantly reduced losses from predators by installing durable hexagon chicken wire enclosures, leading to improved flock health and increased operational efficiency. This investment in quality mesh, despite its initial hexagonal wire mesh price, paid for itself through sustained productivity and reduced maintenance. Similarly, a major civil engineering firm utilized heavy-duty galvanized hexagonal wire mesh to construct gabion retaining walls for a challenging riverside erosion control project. The flexibility of the mesh allowed for natural settlement and adaptation to terrain, providing a stable and aesthetically pleasing solution that has withstood several flood seasons, demonstrating the long-term cost-effectiveness and durability of the material.

Another compelling case involves a large-scale construction development that required extensive insulation support. By opting for galvanized hexagonal mesh, the project achieved efficient and secure fastening of insulation materials, complying with stringent building codes while optimizing installation time. The consistent quality and precise hexagonal wire mesh sizes supplied ensured seamless integration into the building structure. These examples underscore the tangible benefits and return on investment that businesses can achieve by selecting the appropriate hexagonal wire mesh, highlighting that the initial hexagonal wire mesh price is an investment in long-term performance and reliability across diverse industrial and commercial applications.

Frequently Asked Questions (FAQ)

Q: What factors most significantly impact the hexagonal wire mesh price?

A: The primary factors include raw material cost (steel wire), wire gauge (thicker wire means higher cost), mesh opening size (smaller openings increase material use), type of coating (galvanized vs. PVC coated), and order volume. Specific market conditions and shipping logistics also play a role.

Q: How does PVC coating affect the hexagonal wire mesh price and durability?

A: PVC coating generally increases the hexagonal wire mesh price due to the additional material and process. However, it significantly enhances durability, especially in corrosive environments (e.g., coastal areas) or where aesthetic appeal is desired, extending the service life and reducing maintenance costs in the long run.

Q: What are common hexagonal wire mesh sizes available?

A: Common mesh openings range from 1/2 inch to 3 inches, with corresponding wire gauges from 27 BWG to 14 BWG. Roll widths typically range from 0.5 meters to 2 meters, and lengths from 25 meters to 50 meters, though custom sizes are also available from specialized manufacturers.

Q: What is the typical lead time for large orders?

A: Lead times can vary based on order size, customization requirements, and current production schedules. For standard items, it might be 2-4 weeks. For large or highly customized orders, it could extend to 6-8 weeks. We recommend discussing your specific needs with our sales team for an accurate estimate.

Q: Do you provide a warranty or quality guarantee for your hexagonal wire mesh?

A: Yes, we stand by the quality of our products. All our hexagonal wire mesh products come with a quality guarantee against manufacturing defects, and specific warranty periods apply based on the product type and coating. Our commitment to ISO 9001 standards ensures consistent quality and performance.

Delivery, Warranty, and Customer Support

Timely and reliable delivery is a cornerstone of our service commitment. We operate with efficient logistics networks to ensure that your hexagonal wire mesh orders, regardless of volume or complexity, reach your designated location promptly and in perfect condition. Our robust packaging minimizes transit damage, preserving the quality of the mesh from our factory to your site. We understand that project timelines are critical, and our delivery schedules are managed to align with your operational needs, ensuring continuity and preventing costly delays. We also offer various shipping options to accommodate urgent requests and specific logistical challenges, reflecting our dedication to comprehensive customer service that extends beyond the initial hexagonal wire mesh price discussion.

Our commitment to quality is underscored by our comprehensive warranty and dedicated customer support. Every batch of hexagonal wire mesh undergoes rigorous quality control inspections, meeting or exceeding international standards such as ISO and ASTM. We provide a clear warranty period for our products, covering manufacturing defects and ensuring peace of mind for our clients. Our experienced technical support team is readily available to assist with product selection, installation guidance, and any post-purchase inquiries. This holistic approach to service ensures that your investment in our hexagonal wire mesh delivers enduring value, reinforcing our position as a trusted partner in your industrial sourcing needs.

Conclusion: Strategic Sourcing for Optimal Value

In conclusion, understanding the nuances of hexagonal wire mesh price involves a comprehensive evaluation of material type, wire gauge, mesh size, coating, and the reputation of the manufacturer. While the initial cost is a factor, prioritizing long-term durability, performance, and adherence to international quality standards will ultimately yield greater value and reduce overall project expenditures. Choosing a supplier like WireMeshPro that offers transparent pricing, customization options, and robust after-sales support ensures that your procurement decision is not just cost-effective but also strategically sound for your business operations and project success. The versatility and reliability of hexagonal wire mesh make it an indispensable material across numerous industries, from agriculture to civil engineering, promising enduring utility when sourced correctly.

References

- International Organization for Standardization. ISO 9001:2015, Quality management systems – Requirements.

- American Society for Testing and Materials. ASTM A641/A641M-19, Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire.

- European Committee for Standardization. EN 10244-2:2009, Steel wire and wire products – Non-ferrous metallic coatings on steel wire – Part 2: Zinc or zinc alloy coatings.

- US Department of Agriculture. USDA NRCS Engineering Field Handbook. Chapter 14: Gabions and Rock Revetments.

-

Metal Products Company Galvanized Cable for SaleNewsAug.06,2025

-

Maintenance of Rock Wall with Wire MeshNewsAug.06,2025

-

Loop Tie Wire Cost Effective OptionsNewsAug.06,2025

-

High Quality Cable Cu Xlpe Swa Pvc SupplyNewsAug.06,2025

-

Durable Hexagonal Mesh Wire ProductsNewsAug.06,2025

-

Baling Wire Direct Reliable ServiceNewsAug.06,2025

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025