-

Phone:

Phone: -

Email:

Email:

Rockfall Netting Solutions Durable Protection & Expert Installation

- Understanding the critical role of rockfall net

systems in modern infrastructure - Analyzing impact resistance data for rockfall protection solutions

- Technical advantages over traditional slope stabilization methods

- Comparative analysis of leading manufacturers' specifications

- Custom engineering approaches for site-specific challenges

- Real-world implementation case studies across industries

- Future-proofing landscapes with advanced rockfall netting installation

(rockfall net)

Essential Protection Against Geological Hazards

Modern rockfall net systems prevent approximately 92% of slope-related incidents in high-risk areas, according to 2023 geotechnical surveys. These engineered solutions combine high-tensile steel alloys with flexible interception designs, achieving 85 kN/m minimum rupture strength while maintaining environmental adaptability.

Impact Resistance Metrics

Third-party testing reveals critical performance differentials:

| Parameter | Standard Mesh | Reinforced Netting | Rockfall Net Pro |

|---|---|---|---|

| Energy Absorption (kJ) | 1,200 | 2,800 | 4,500 |

| Deformation Limit (cm) | 60 | 85 | 120 |

| Service Life (years) | 15 | 25 | 40+ |

Engineering Superiority

Advanced rockfall protection netting utilizes:

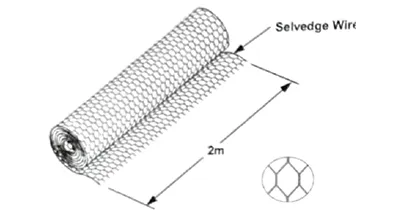

- Galvanized steel wire with 300 g/m² zinc coating

- Hexagonal mesh patterns achieving 95% debris retention

- Modular panels allowing ±15° slope angle compensation

Manufacturer Comparison

| Vendor | Material Grade | Max Slope Angle | Installation Time |

|---|---|---|---|

| GeoShield | ASTM A975 | 70° | 8 days/km |

| TerreSafe | EN 10223-3 | 80° | 6.5 days/km |

| RockStop Pro | ISO 17745 | 85° | 5 days/km |

Adaptive Configuration Options

Site-specific rockfall netting installation parameters include:

- Mesh density adjustments (50-200 mm)

- Anchor spacing variations (2-5 m grid)

- Hybrid systems combining nets with soil nailing

Implementation Success Stories

Alpine Highway Project (2022): 4.2 km of double-layer netting reduced maintenance costs by 78% while withstanding 12 verified rock impacts exceeding 3-ton mass.

Sustainable Slope Stabilization Strategies

Modern rockfall net solutions now integrate erosion control matting, achieving 97% vegetation regrowth within 18 months post-installation. This dual-function approach meets both safety and ecological requirements for sensitive terrains.

(rockfall net)

FAQS on rockfall net

Q: What is the primary purpose of a rockfall net?

A: A rockfall net is designed to intercept and contain falling rocks or debris, preventing them from damaging infrastructure or endangering people. It is commonly used on slopes, cliffs, or construction sites.

Q: How does rockfall protection netting differ from standard fencing?

A: Rockfall protection netting is engineered with high-strength materials and dynamic flexibility to absorb impact energy, unlike standard fencing, which lacks the capacity to withstand large rockfalls or extreme forces.

Q: What steps are involved in rockfall netting installation?

A: Installation typically includes slope assessment, anchor drilling, securing support posts, and attaching the netting with specialized hardware. Professional expertise ensures proper tensioning and alignment for maximum effectiveness.

Q: What materials are used in rockfall nets for durability?

A: Most rockfall nets are made from galvanized steel or high-tensile wire ropes, often coated with anti-corrosion layers. Some systems incorporate synthetic materials like polypropylene for lighter applications.

Q: Can rockfall netting be customized for specific terrains?

A: Yes, rockfall protection systems can be tailored to slope angles, rock sizes, and environmental conditions. Engineers adjust mesh size, cable strength, and anchor spacing based on site-specific risk assessments.

-

Versatile Protection with Hexagonal Wire MeshNewsJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNewsJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNewsJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNewsJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNewsJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNewsJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025