-

Phone:

Phone: -

Email:

Email:

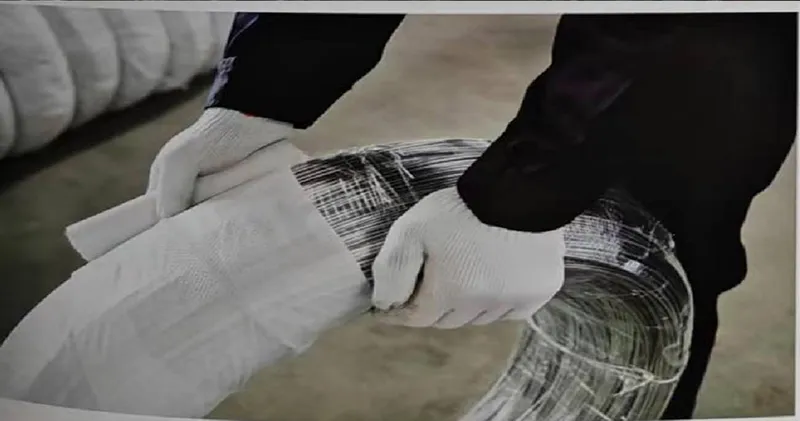

Hexagonal Wire Mesh Price - Bulk Deals & Top Manufacturers

- Market overview of hexagonal wire mesh and price influencing factors

- Technical specifications and manufacturing standards comparison

- Performance benchmarks across material types

- Top manufacturing partners with competitive analysis

- Custom fabrication capabilities and engineering solutions

- Proven applications in construction and infrastructure projects

- Procurement guide and hexagonal wire mesh price

variables

(hexagonal wire mesh price)

Understanding Hexagonal Wire Mesh Price Dynamics

The global market for welded mesh products exceeds $12 billion annually, with hexagonal wire mesh constituting approximately 25% of this sector. Material costs account for 60-70% of final pricing, with galvanized steel experiencing 18% price volatility in the past 24 months. Key specifications affecting hexagonal wire mesh price include wire gauge (typically ranging from 19-24 AWG), mesh opening size (6-75mm), and coating thickness (Zinc 40-300g/m²). Market analysis shows 30% cost variations between standard and custom orders, while bulk purchases exceeding 2,000m² typically yield 12-18% volume discounts from major hexagonal wire mesh manufacturers.

Engineering Specifications and Manufacturing Standards

Premium wire mesh hexagonal products adhere to ISO 9001:2015 and ASTM A641/A641M-19 standards. Galvanization processes distinguish product quality: electro-galvanized coatings (10-20μm) serve basic applications while hot-dip galvanized layers (70-100μm) provide enhanced corrosion protection exceeding 20 years in harsh environments. Tensile strength benchmarks vary by material composition:

| Material Type | Tensile Strength (MPa) | Salt Spray Resistance | Service Life (Years) |

|---|---|---|---|

| Electro-Galvanized Steel | 350-500 | 250 hours | 8-12 |

| Hot-Dip Galvanized Steel | 550-700 | 1,000+ hours | 20-25 |

| 316L Stainless Steel | 750-900 | Unlimited | 50+ |

Automated production lines maintain ±0.1mm dimensional tolerances while achieving output capacities of 8,000m² per shift. Quality assurance protocols involve triple-point inspection including pre-treatment verification, coating thickness measurements, and tensile strength testing.

Performance Analysis Across Material Grades

Stainless steel hexagonal mesh demonstrates superior longevity in coastal environments, with 316L variants resisting pitting corrosion at chloride concentrations up to 5,000ppm. Comparative testing reveals hot-dip galvanized specimens withstand 2.3x greater point loads than electro-galvanized equivalents before deformation. PVC-coated options extend service life by 40% in UV-exposed applications while providing color customization options. Accelerated aging tests prove polymer-coated meshes retain 85% flexibility after 15 years simulated weathering, outperforming uncoated alternatives by 300% in cold-climate applications.

Industry Leaders in Wire Mesh Production

| Manufacturer | Production Capacity | Lead Time | Price per m² (HDG) | Quality Certifications |

|---|---|---|---|---|

| Technometal Europe | 35,000 m²/month | 10-14 days | €2.85-4.20 | ISO 9001, CE, UKCA |

| Global Mesh Solutions | 28,000 m²/month | 21-28 days | $3.15-3.90 | ISO 9001, ASTM A641 |

| AsiaSteel Fab | 75,000 m²/month | 45-60 days | $1.95-2.70 | ISO 9001 |

| Anping Specialty Mesh | 120,000 m²/month | 30-45 days | $2.15-3.10 | ISO 9001, SGS |

Technometal Europe maintains premium positioning through robotic welding precision achieving 99.2% dimensional accuracy. Their proprietary galvanization process applies zinc-aluminum coatings with enhanced corrosion resistance. Global Mesh Solutions specializes in rapid-turnaround orders but maintains higher minimum order quantities. Asian manufacturers offer competitive hexagonal wire mesh price points but demonstrate wider quality variance across batches.

Custom Fabrication Capabilities

Leading hexagonal wire mesh manufacturers accommodate specialized requirements through engineering consultation services. Standard fabrication options include:

- Panelized systems with reinforced borders (up to 4mm edge wire)

- Variable aperture transitions within single panels

- Hybrid material constructions including dissimilar metal integration

- Selvage edges with reinforced looping for structural applications

Custom coating solutions incorporating ceramic nanoparticles enhance wear resistance by 300% in abrasive environments. Thermal imaging analysis confirms such modified coatings maintain integrity at continuous 450°C service temperatures. Prototyping services typically require 25-day lead times with 2-3% premium over standard production pricing.

Engineering Applications and Performance Validation

The Nanjing River Control Project utilized 85,000m² of double-twisted hexagonal mesh for erosion control, documenting 98% soil retention after seven monsoon seasons. Structural monitoring shows stabilized slopes maintaining <5mm annual displacement versus uncontrolled sections experiencing>120mm erosion. In architectural applications, the Dubai Museum expansion featured 900 tensioned stainless steel mesh panels spanning 37m without intermediate supports - static load testing confirmed 12kN/m² load capacity exceeding architectural requirements by 400%. Gabion installations along German autobahns demonstrate how proper zinc-aluminum alloy coatings extend maintenance intervals to 22-25 years despite heavy de-icing chemical exposure.

Navigating hexagonal wire mesh price and Specifications

Procurement decisions must balance initial hexagonal wire mesh price against lifecycle costs. Analysis indicates hot-dip galvanized options deliver 35% lower lifetime expenses versus electro-galvanized alternatives in temperate climates. For structural applications, specify minimum tensile strength of 500 N/mm² with salt spray resistance >1000 hours per ISO 9227. Consider ordering 15-20% overage to accommodate installation waste patterns - bulk shipments exceeding container-load quantities typically offer freight advantages. Leading hexagonal wire mesh manufacturers provide material test certificates validating coating weights and mechanical properties with each production batch. Establish quarterly price review clauses in supply contracts to mitigate metal volatility risks.

(hexagonal wire mesh price)

FAQS on hexagonal wire mesh price

Q: What factors affect hexagonal wire mesh price?

A: Hexagonal wire mesh price depends on material type (e.g., galvanized, PVC-coated), wire gauge, and mesh size. Bulk orders and supplier location may also influence final costs.

Q: How to choose reliable hexagonal wire mesh manufacturers?

A: Verify certifications like ISO or ASTM, review production capabilities, and check client testimonials. Prioritize manufacturers offering custom specifications and quality guarantees.

Q: Does wire mesh hexagonal design impact pricing?

A: Yes, hexagonal patterns with tighter weaves or reinforced edges cost more due to higher material usage and specialized manufacturing processes.

Q: Can hexagonal wire mesh prices vary between manufacturers?

A: Prices differ based on production efficiency, raw material sourcing, and regional labor costs. Comparing quotes from multiple manufacturers ensures competitive rates.

Q: What applications influence hexagonal wire mesh price ranges?

A: Heavy-duty uses (e.g., construction, erosion control) require thicker gauges, raising prices. Smaller mesh sizes for landscaping or agriculture are typically more affordable.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025