-

Phone:

Phone: -

Email:

Email:

Jan . 24, 2025 05:55

Back to list

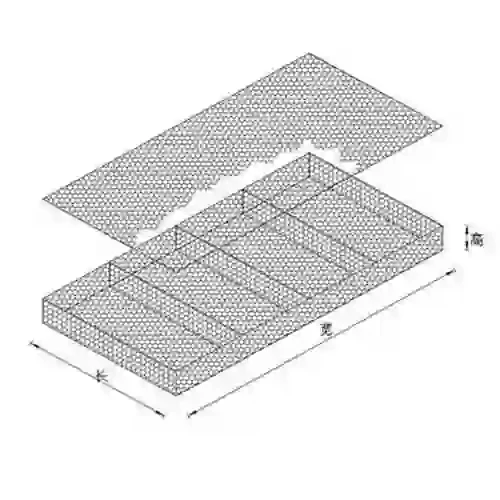

Riverbank Stabilization Structure

Binding wire, an essential component in various construction and industrial applications, is often overlooked despite its crucial role. This thin, flexible, and durable wire primarily serves to tie and secure rebars in reinforced concrete structures. But its uses extend beyond the construction site, touching different industries that value its adaptability and strength.

Artisans and craftsmen also appreciate binding wire for its creative potential. In sculpture, jewelry making, and floral arrangements, binding wire provides the flexibility and strength required to hold components together, allowing artists to manipulate materials into desired shapes without breaking. Thus, it serves both functional and aesthetic purposes. When discussing binding wire, one cannot ignore its role in emergency repairs. Its quick-fix capability makes it a go-to material for temporary solutions in cases where fastening or holding together materials is required. From mending fences to temporary fixture repairs, binding wire offers a last-minute solution until a more permanent fix can be arranged. When selecting binding wire, quality is paramount. Ensuring the wire is galvanized or coated can protect it from corrosion, extending its lifespan and maintaining its integrity in various environments. This feature is particularly crucial for outdoor applications where exposure to the elements is a concern. In conclusion, binding wire’s diverse applications across industries illustrate its indispensable nature. As a product category, it demands attention not only for its functional attributes but also for the wide-ranging industries it supports. Its strength, versatility, and cost-effectiveness make it a critical tool in both professional and personal contexts. For those involved in industries reliant on secure fastening and stability, understanding binding wire's potential can significantly enhance operational efficiency and safety.

Artisans and craftsmen also appreciate binding wire for its creative potential. In sculpture, jewelry making, and floral arrangements, binding wire provides the flexibility and strength required to hold components together, allowing artists to manipulate materials into desired shapes without breaking. Thus, it serves both functional and aesthetic purposes. When discussing binding wire, one cannot ignore its role in emergency repairs. Its quick-fix capability makes it a go-to material for temporary solutions in cases where fastening or holding together materials is required. From mending fences to temporary fixture repairs, binding wire offers a last-minute solution until a more permanent fix can be arranged. When selecting binding wire, quality is paramount. Ensuring the wire is galvanized or coated can protect it from corrosion, extending its lifespan and maintaining its integrity in various environments. This feature is particularly crucial for outdoor applications where exposure to the elements is a concern. In conclusion, binding wire’s diverse applications across industries illustrate its indispensable nature. As a product category, it demands attention not only for its functional attributes but also for the wide-ranging industries it supports. Its strength, versatility, and cost-effectiveness make it a critical tool in both professional and personal contexts. For those involved in industries reliant on secure fastening and stability, understanding binding wire's potential can significantly enhance operational efficiency and safety.

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS