-

Téléphone:

Téléphone: -

E-mail:

E-mail:

Why Hexagonal Wire Mesh Is the Flexible Powerhouse for Slope and Structural Reinforcement

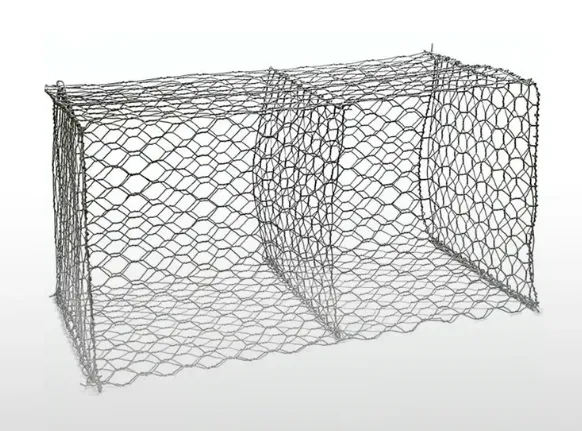

Across industries, from civil engineering to agriculture, one material continues to earn praise for its reliability, versatility, and long-term value: hexagonal wire mesh. Known for its distinct twisted design and exceptional adaptability, this mesh is the go-to choice for slope protection, gabions, fencing, and erosion control. As demands for safer, more cost-effective infrastructure rise, leading projects around the globe are turning to high-quality hexagonal wire mesh solutions.

Grillage hexagonal:Selecting the Right Mesh Size and Wire Diameter

Choosing the correct specifications for your hexagonal wire mesh is critical to achieving the desired strength and function. Mesh size generally ranges from 0.5 to 4 inches, with smaller openings used to prevent soil erosion or contain fine materials, and larger openings ideal for rockfall control or gabion walls. The wire diameter typically varies between 0.5 mm and 3.0 mm, and selecting the right thickness depends on both load-bearing requirements and environmental exposure.

For heavy-duty uses like retaining structures or riverbank stabilization, double twisted hexagonal wire mesh offers superior tensile strength and resistance to deformation. The twist not only enhances durability but also ensures that damage in one area does not unravel the entire structure. Whether reinforcing a highway slope or enclosing livestock, understanding the balance between mesh size and wire thickness ensures your project remains secure and cost-efficient.

Reinforcing Strength: Why Edge Handling Is Essential in Hexagonal Wire Mesh

One often-overlooked factor in installing hexagonal wire mesh is how the edges are finished and reinforced. The edges bear a significant part of the load and tension in any installation, and poor handling can compromise the entire structure. To maintain mesh integrity, it’s critical to use edge wires that are either looped or tightly knotted, especially in applications like gabions or fencing.

Our latest models of pvc coated hexagonal wire mesh not only provide edge rigidity but also resist corrosion and fraying over time. The plastic coating adds a layer of protection in humid or marine environments while improving visual appeal. Reinforced borders ensure that even under tension or repeated impacts, the mesh retains its form and function—essential for long-term projects on demanding terrain.

Beyond the Flatlands: Why Hexagonal Wire Mesh Excels on Irregular Terrain

Compared to welded wire mesh, hexagonal wire mesh shines on uneven or irregular landscapes. Its twisted wire structure allows it to flex and mold to hillsides, embankments, or rocky terrain without snapping or deforming. This makes it the first choice for erosion control on slopes, river channels, and mountain infrastructure.

Welded mesh, by contrast, is rigid and prone to breaking under natural shifts in the earth, especially during temperature fluctuations or seismic activity. Double twisted hexagonal wire mesh absorbs movement while maintaining load stability, reducing repair costs and structural risks. Whether installed as a flexible retaining structure or as part of a gabion mattress, its adaptability and resilience make it the industry’s most terrain-friendly solution.

Trusting the Best: Finding Reliable Hexagonal Wire Mesh Manufacturers

Choosing top-tier hexagonal wire mesh manufacturers ensures not only quality materials but also technical support and customization. Our production process includes tensile strength testing, galvanization or PVC coating for corrosion resistance, and strict quality control to meet global engineering standards.

As one of the most trusted hexagonal wire mesh manufacturers, we offer tailored solutions that suit a wide range of applications, including flood control, mining operations, and fencing. Our technical team collaborates with engineers and contractors to select the right mesh design, coating, and dimensions, ensuring that your investment performs at the highest level throughout its service life.

Smart Investment: Comparing Hexagonal Wire Mesh Price with Long-Term Value

While some may hesitate at the upfront hexagonal wire mesh price, the long-term savings speak for themselves. Its durability, ease of transport, and quick installation translate to significantly lower maintenance and labor costs. When properly installed, pvc coated hexagonal wire mesh can last over 25 years—even in corrosive or abrasive environments.

We offer competitive hexagonal wire mesh price packages based on material specifications, coating type, and order volume. From temporary enclosures to permanent slope reinforcement, our flexible pricing options ensure that every project, big or small, gets the quality and affordability it deserves.

Hexagonal Wire Mesh FAQs

What are the common applications of hexagonal wire mesh?

Hexagonal wire mesh is widely used in slope protection, retaining wall reinforcement, fencing, poultry cages, and gabion structures. Its strength and adaptability make it ideal for both civil and agricultural uses.

Why choose pvc coated hexagonal wire mesh over uncoated options?

Pvc coated hexagonal wire mesh offers enhanced corrosion resistance, especially in humid or marine environments. The coating extends the mesh's lifespan and improves its appearance, making it ideal for both structural and aesthetic applications.

What makes double twisted hexagonal wire mesh stronger than other types?

Double twisted hexagonal wire mesh provides superior stability by ensuring that if one wire breaks, the overall structure remains intact. This is especially useful in high-impact applications like rockfall barriers or gabion walls.

How can I ensure the stability of the edges during installation?

Edges should be reinforced with thicker wires or properly looped closures. This is essential for maintaining the strength of hexagonal wire mesh installations, particularly under tension or shifting ground.

Are all hexagonal wire mesh manufacturers the same?

No, not all hexagonal wire mesh manufacturers maintain the same quality standards. Look for suppliers that offer certified materials, proper coatings, and experienced technical support to ensure long-lasting performance.

-

Versatile Protection with Hexagonal Wire MeshNouvellesJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNouvellesJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNouvellesJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNouvellesJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNouvellesJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNouvellesJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNouvellesJun.09,2025