-

Phone:

Phone: -

Email:

Email:

Does Rebar Tie Wire Experience Rusting Over Time

Does Rebar Tie Wire Rust? Understanding the Corrosion of Rebar Tie Wire and Its Implications in Construction

In the construction industry, ensuring the durability and longevity of structures is of utmost importance. One component that plays a vital role in the integrity of concrete structures is rebar (reinforcing bar) tie wire. This wire is used to secure rebar in place during the pouring of concrete, ensuring that the reinforcement remains in the correct position for optimal structural support. However, a common concern among professionals and DIY enthusiasts alike is whether rebar tie wire can rust and what implications this might have for construction projects.

Does Rebar Tie Wire Rust? Understanding the Corrosion of Rebar Tie Wire and Its Implications in Construction

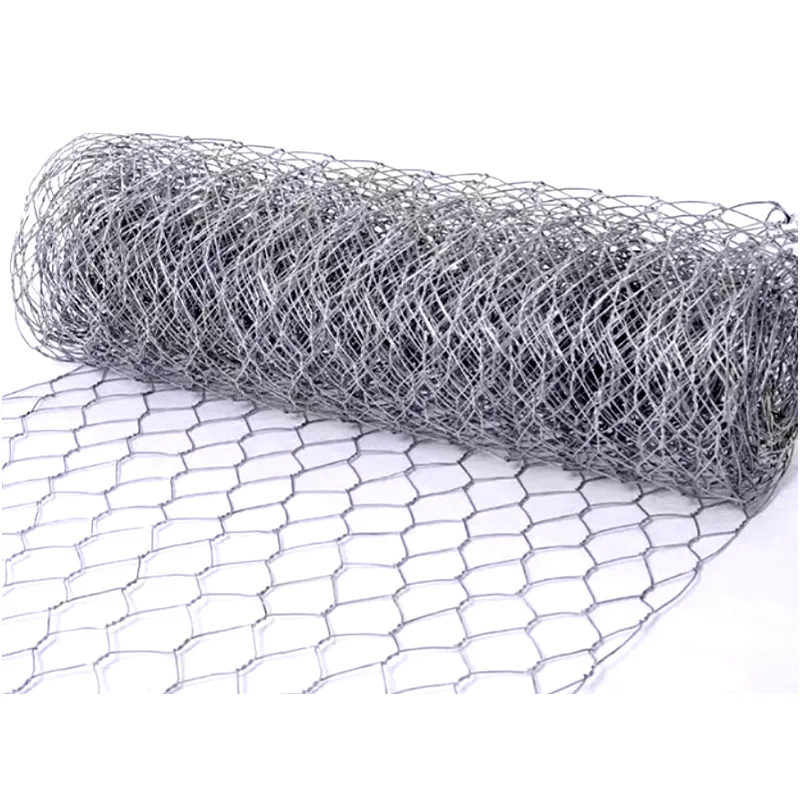

There are primarily two types of rebar tie wire available in the market galvanized and uncoated. Galvanized tie wire has a protective zinc coating that acts as a barrier against moisture and air, significantly reducing the risk of rust and corrosion. This makes galvanized wire an excellent choice for projects where exposure to harsh weather conditions is anticipated. On the other hand, uncoated or bare tie wire is more susceptible to rusting as it lacks any protective coating. In environments with high humidity, exposure to saltwater, or varying temperatures, uncoated tie wire can corrode quickly, leading to potential structural issues.

does rebar tie wire rust

The presence of rust on rebar tie wire may seem minor at first, but it can have significant implications for the overall structural integrity of a construction project. If the tie wire rusts and weakens, it may fail to hold the rebar in place properly during the concrete curing process. This can lead to misalignment of the rebar, undermining the reinforcement’s effectiveness and potentially leading to structural failures in the long run. Moreover, rust can transfer to the surrounding concrete, which may eventually lead to spalling and cracks as the corrosion process expands.

To mitigate the risk of rusting, several best practices can be followed during the construction process. First and foremost, the use of galvanized tie wire is highly recommended, particularly in environments prone to moisture and corrosion. Additionally, proper storage of tie wire on-site is essential. Keeping the wire in a dry location and avoiding direct contact with the ground can help prevent rust development. It’s also important to use the correct tying techniques to minimize exposure to air and moisture during the construction phase.

Furthermore, regular inspections should be conducted to check for any signs of rust or corrosion on the tie wire and rebar. If rust is detected, it is crucial to address the issue promptly, potentially replacing any compromised materials. In some cases, applying a rust-resistant coating or sealant may extend the life of the wire and rebar, providing an additional layer of protection against the elements.

In conclusion, while rebar tie wire can rust, the extent to which it affects construction projects largely depends on the type of wire used and the surrounding environmental conditions. By opting for galvanized tie wire, following best storage practices, and conducting regular inspections, contractors can significantly reduce the risks associated with rust and ensure the long-term durability of their structures. Understanding the properties of rebar tie wire and implementing preventive measures against corrosion will enhance the safety and stability of concrete constructions, leading to a more resilient infrastructure.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025