-

Telefono:

Telefono: -

E-mail:

E-mail:

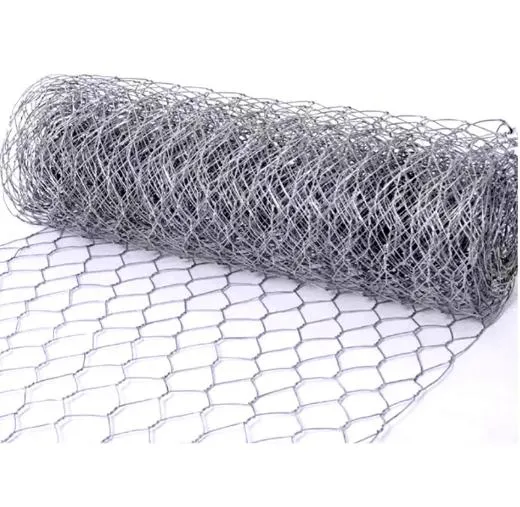

Uncompromised Slope Safety with Advanced Rockfall Protection Netting

When nature threatens infrastructure and safety, our engineered rockfall protection netting stands as the first line of defense. Designed to catch, contain, and control falling rocks and debris on steep slopes, mountainsides, and excavation sites, our high-performance rock netting solutions are trusted by governments, contractors, and developers worldwide.

When Should Rockfall Protection Netting Be Installed?

Rockfall protection netting should be installed in areas where the risk of falling rocks, debris, or loose soil poses a threat to infrastructure, transportation routes, or human safety. These include highways cut through mountainous terrain, railways bordering rocky slopes, mining excavation walls, tunnels, dams, and even residential areas developed on steep terrain.

If geological surveys or visual inspections reveal evidence of fractured rock formations, loose boulders, or prior rockfall activity, installing rock netting becomes a proactive necessity. Weather patterns such as heavy rainfall, seismic activity, or freeze-thaw cycles can loosen rocks and increase the likelihood of falls. In such conditions, relying on temporary signage or concrete barriers is not enough—rockfall protection netting offers a permanent, adaptive solution.

In construction projects where slopes are excavated or reshaped, rockfall protection netting must be included as part of the safety design from the planning phase. It reduces long-term maintenance costs and prevents dangerous disruptions caused by falling material. For highways and railways that serve as major transportation arteries, protecting these corridors with rock netting is not just a safety measure—it’s a vital investment in operational continuity.

How Much Force Can Rockfall Protection Netting Withstand?

Our engineered rockfall protection netting is designed to absorb and resist extreme impact forces from free-falling rocks and high-speed debris. Made from high-tensile galvanized steel wire, the netting features exceptional load-bearing capacity, capable of withstanding impact energies up to several thousand kilojoules—depending on the system type, mesh density, and anchoring configuration.

The effectiveness of rock netting lies in its dynamic response to impact. When a rock falls and hits the net, the force is distributed across the mesh and anchor points, dissipating the energy without tearing or failure. Standard systems can absorb energy levels between 100 to 2,000 kJ, suitable for medium to large rockfall events. High-performance systems, used in areas of extreme hazard, can be engineered to withstand impacts exceeding 5,000 kJ.

To achieve this, the steel wires used in our rockfall protection netting are not only thick and tightly twisted, but also treated to resist fatigue and corrosion. The structure allows flexibility while maintaining overall strength—an essential trait for protection across varying topography.

As a result, municipalities, mining operators, and developers trust our systems to offer real protection. Our rock netting cost reflects not only superior material quality but also the peace of mind that comes with trusted performance in life-critical applications.

Which National and International Standards Does Rockfall Netting Comply With?

Ensuring compliance with national and international safety regulations is a top priority for us as premium rockfall netting suppliers. Our rockfall protection netting meets or exceeds key industry standards that govern the performance, quality, and installation of slope protection systems.

All our rock netting products comply with EN 14490, the European standard for soil nailing, reinforced soil, and anchoring systems, which includes specifications for rockfall barriers. In addition, our high-energy absorption systems are tested in accordance with ETAG 027 (now EAD 340059-00-0106), which evaluates dynamic performance under standardized impact testing.

For clients in North America, our rockfall protection netting conforms to ASTM A975 for double-twisted mesh used in rockfall applications, as well as ASTM A1064 for steel wire reinforcement. Galvanized components follow ASTM A641 and EN 10244 standards for corrosion resistance and coating thickness.

Working with our team ensures you receive certified documentation and test results for every system delivered. We don’t just supply wire—we deliver confidence. Whether for civil engineering tenders, government safety projects, or international infrastructure contracts, our rock netting passes every test.

The True Value Behind Rock Netting Cost and Long-Term Protection

While the upfront rock netting cost may vary depending on project scope, terrain complexity, and system specifications, the long-term value it provides is unmatched. Our rockfall protection netting saves lives, prevents property damage, and eliminates costly delays associated with slope failure and cleanup operations.

Each system is tailored to your site, combining appropriate mesh type, anchor strength, and installation method. Our rock netting can be installed in draped configurations, guided mesh panels, or fully anchored high-energy absorption barriers depending on the rockfall threat level. This custom approach ensures optimal performance without overengineering or overspending.

Unlike concrete barriers or rigid retaining walls that deteriorate over time, our rock netting maintains integrity for decades with minimal maintenance. The corrosion-resistant finish ensures reliability in wet, salty, or acidic environments. Our support team also provides design consultation, cost analysis, and installation training to maximize your return on investment.

For large-scale projects requiring international compliance and guaranteed safety, working with certified rockfall netting suppliers like us gives you the advantage of quality, expertise, and on-time delivery—every time.

Rockfall Protection Netting FAQs

When is rockfall protection netting necessary on a site?

Rockfall protection netting is needed when geological assessments reveal unstable rock formations, previous rockfall incidents, or environmental conditions that may loosen debris on slopes adjacent to roads, tunnels, railways, or populated areas.

How much force can your rock netting systems handle?

Our rock netting systems can withstand impact energies ranging from 100 kJ to over 5,000 kJ, depending on the design. This allows them to absorb the force of large boulders falling from significant heights.

What certifications do your rockfall protection netting products meet?

Our rockfall protection netting complies with EN 14490, ETAG 027/EAD 340059-00-0106, ASTM A975, and ASTM A1064, ensuring global safety and performance standards are met.

How do you determine rock netting cost for a project?

Rock netting cost depends on factors such as mesh type, project area, slope angle, anchoring method, and local environmental conditions. We provide customized quotes based on site surveys and engineering requirements.

Why choose your company among other rockfall netting suppliers?

As experienced rockfall netting suppliers, we offer certified materials, engineering support, compliance documentation, and international logistics capabilities—delivering complete solutions on time and on budget.

-

Wire Mesh for Every Need: A Practical SolutionNotiziaJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNotiziaJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNotiziaJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNotiziaJul.25,2025

-

Affordable Iron Binding Wire SolutionsNotiziaJul.25,2025

-

Affordable Galvanized Wire SolutionsNotiziaJul.25,2025

-

Wire Hanger Recycling IdeasNotiziaJul.25,2025