-

Phone:

Phone: -

Email:

Email:

2月 . 17, 2025 15:35

Back to list

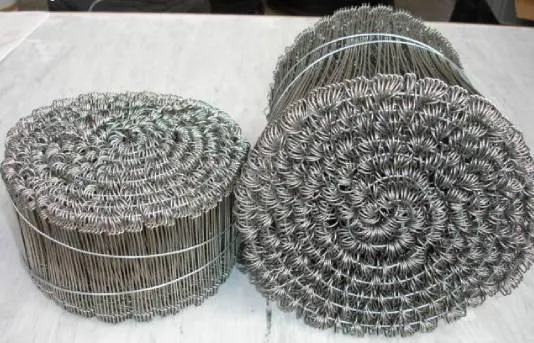

Loop Tie Wire

The question of whether rebar tie wire rusts may seem straightforward, but it delves into the intricacies of construction materials and the environmental conditions they face. Understanding the behavior of rebar tie wire in various settings is crucial for both professionals in the construction industry and DIY enthusiasts.

Experts argue that for most typical construction applications, standard tie wire will suffice, given that the concrete it supports provides significant protection once cured. The alkaline nature of concrete forms a passive oxide layer on the steel, which inhibits corrosion. However, for projects where the integrity and longevity of the structure are paramount, specifying corrosion-resistant materials can lead to significant long-term benefits. To add authority to this understanding, numerous studies and real-world applications back the use of protective coatings on rebar tie wire. Published research from materials science journals indicates that the selection of the tie wire's material can impact the lifespan of concrete structures. Trustworthiness in construction guidelines often recommends adherence to standards set forth by bodies like ACI (American Concrete Institute) and ASTM International, which provide detailed recommendations on the use of materials in different environmental settings. For project managers and construction teams, assessing the specific environmental conditions and determining the appropriate material for rebar tie wire is a complex equation of cost, safety, and longevity. Simply put, knowing when to invest in higher-grade materials can prevent costly repairs down the road and also assure the safety and durability of the structure. In summary, while rebar tie wire is susceptible to rust, the extent can be managed and mitigated through informed material choices and construction practices. By integrating real-world experience with expert recommendations and authoritative guidelines, the issue of corrosion can be effectively addressed, ensuring the longevity and reliability of concrete structures under a range of environmental conditions.

Experts argue that for most typical construction applications, standard tie wire will suffice, given that the concrete it supports provides significant protection once cured. The alkaline nature of concrete forms a passive oxide layer on the steel, which inhibits corrosion. However, for projects where the integrity and longevity of the structure are paramount, specifying corrosion-resistant materials can lead to significant long-term benefits. To add authority to this understanding, numerous studies and real-world applications back the use of protective coatings on rebar tie wire. Published research from materials science journals indicates that the selection of the tie wire's material can impact the lifespan of concrete structures. Trustworthiness in construction guidelines often recommends adherence to standards set forth by bodies like ACI (American Concrete Institute) and ASTM International, which provide detailed recommendations on the use of materials in different environmental settings. For project managers and construction teams, assessing the specific environmental conditions and determining the appropriate material for rebar tie wire is a complex equation of cost, safety, and longevity. Simply put, knowing when to invest in higher-grade materials can prevent costly repairs down the road and also assure the safety and durability of the structure. In summary, while rebar tie wire is susceptible to rust, the extent can be managed and mitigated through informed material choices and construction practices. By integrating real-world experience with expert recommendations and authoritative guidelines, the issue of corrosion can be effectively addressed, ensuring the longevity and reliability of concrete structures under a range of environmental conditions.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS