-

Phone:

Phone: -

Email:

Email:

Durable Steel Wire Solutions for Binding and Securing Materials in Various Industries

The Versatility of Tie Steel Wire A Comprehensive Overview

Tie steel wire, often referred to as binding wire, is a crucial component in various industries and construction applications. Composed primarily of high-carbon steel, this wire is known for its strength, durability, and versatility. Its primary purpose is to hold materials together, bind elements in construction, and offer support in a myriad of uses. Understanding the properties and applications of tie steel wire can provide insight into its significance in modern construction and manufacturing processes.

Composition and Characteristics

Tie steel wire is typically made from drawn steel wire with a high tensile strength, allowing it to withstand significant loads without deformation. It is often coated with materials such as zinc to enhance its resistance to corrosion, making it suitable for both indoor and outdoor applications. The wire is available in various diameters and can be easily manipulated into different shapes, which adds to its adaptability.

One of the most notable characteristics of tie steel wire is its excellent ductility, allowing it to stretch rather than break under pressure. This property is invaluable in construction, where workers often need to twist, bend, or wrap the wire to secure materials together. Additionally, tie steel wire can be pulled and cut easily, facilitating quick and efficient use in various tasks.

Applications in Construction

In the construction industry, tie steel wire plays a pivotal role in reinforcing structures

. It is commonly used for tying rebar together, ensuring that the reinforcement bars remain in place during the concrete pouring process. This chaining effect not only stabilizes the rebar but also contributes to the overall strength of the concrete structure once it has cured.Moreover, tie steel wire is integral to formwork systems, where it is used to hold forms in position while concrete is being poured. It can also be employed in fencing solutions, acting as a binding resource for chain-link fences and other materials. Its strength and flexibility make it an ideal choice for creating tension in various structures, from temporary scaffolding to permanent installations.

tie steel wire

Uses Beyond Construction

While tie steel wire is predominantly used in construction, its applications extend beyond this field. In agriculture, it is used for binding plants and securing them to stakes, thereby promoting healthy growth and stability. Gardeners often utilize tie steel wire for supporting trellises or forming protective enclosures around delicate plants.

Additionally, tie steel wire finds utility in the manufacturing sector, where it is used in the production of wire mesh, screens, and other metal products. It aids in the assembly of various goods, ensuring that components are securely bound together during transport and throughout their lifecycle.

Environmental Considerations and Innovations

As environmental awareness rises, the steel industry has taken steps towards sustainability. Many manufacturers focus on producing tie steel wire using recycled materials, reducing the overall carbon footprint of production. Furthermore, advancements in coating technologies have led to more efficient corrosion-resistant products, extending the lifespan of tie steel wire in various applications.

Conclusion

In summary, tie steel wire is an indispensable material in both construction and a range of other industries. Its unique properties of strength, flexibility, and durability make it the preferred choice for binding and reinforcing materials across various applications. As both environmental stewardship and technological innovation advance, tie steel wire will continue to play a crucial role in supporting infrastructure and industrial growth, emphasizing its significance in everyday applications. Whether in construction, agriculture, or manufacturing, tie steel wire remains a testament to the essential nature of robust materials in our modern world.

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025

-

The Smart Choice of Chain Link FenceNewsJun.09,2025

-

Securing the Future with Time-Tested Barbed Wire ProtectionNewsJun.09,2025

-

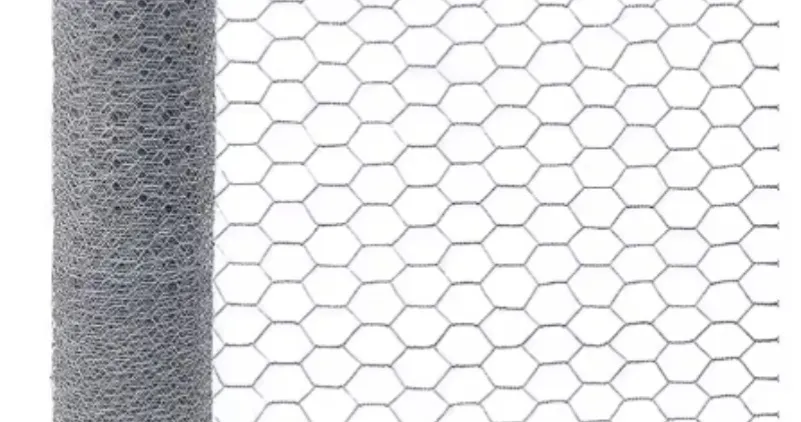

Reliable and All-Season Fencing with Premium Hexagonal Wire MeshNewsJun.09,2025

-

High-Performance Binding Solutions with Premium Loop Tie WireNewsJun.09,2025

-

Durable, Flexible, and High-Performance Baling Wire for SaleNewsJun.09,2025

-

Unveiling the Versatility of Hexagonal Wire MeshNewsMay.21,2025