-

Phone:

Phone: -

Email:

Email:

Custom Wire Handles for Various Applications from Leading Manufacturers

The Role of Wire Handles in Manufacturing and Their Significance

In the world of manufacturing, wire handles serve a crucial function across various industries, ranging from packaging to transportation. As a key component in many products, wire handles are designed to be both durable and versatile, making them an essential aspect of the manufacturing process. This article delves into the importance of wire handles, the materials used in their production, and the various applications they serve.

Understanding Wire Handles

Wire handles are typically made from high-strength steel or aluminum, coated with materials like plastic or rubber to enhance grip and prevent corrosion. The design of wire handles can vary greatly depending on their intended use. They can feature simple loops for easy carrying or ergonomic designs that provide comfort and reduce strain during transport.

One of the most significant advantages of wire handles is their lightweight nature, which makes them a preferred choice over bulkier alternatives. This characteristic not only helps in reducing shipping costs but also aids in the efficient handling of products during transit. Moreover, wire handles can be customized in various sizes and shapes, making them adaptable for different needs and applications.

Applications of Wire Handles

Wire handles find use in a wide array of industries, including packaging, retail, construction, and even automotive sectors. In packaging, they are commonly employed in boxes, bags, and containers, providing consumers with a convenient way to transport goods. Whether it's a shopping bag carrying groceries or a box filled with delicate items, wire handles enhance the usability of packaging solutions significantly.

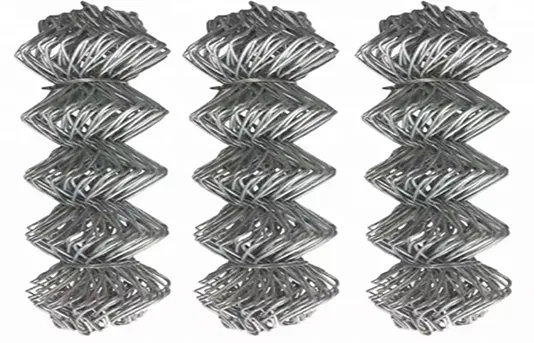

wire handles manufacturer

In the retail sector, wire handles contribute to the overall customer experience. Retail bags featuring sturdy wire handles ensure that consumers can carry their purchases comfortably and securely. Furthermore, businesses may choose to customize these handles with branding to enhance their visibility and create a lasting impression among customers.

The construction and automotive industries also capitalize on wire handles for various tools and equipment. For instance, toolboxes with wire handles allow workers to easily carry essential equipment on-site. In the automotive sector, wire handles are used in various components, such as doors and compartments, providing an efficient and effective means of operation.

The Manufacturing Process

The manufacturing process of wire handles involves several steps to ensure that they meet the required standards for strength and durability. Typically, the process begins with material selection, where manufacturers choose high-quality wires suitable for the intended application. The wires are then shaped and formed into handles using specialized machinery.

Quality control is a critical stage of production, where handles undergo rigorous testing to ensure they can withstand everyday wear and tear. This includes load tests to ascertain their strength and durability under pressure. Once approved, the handles may be coated or finished to prevent corrosion and enhance aesthetic appeal.

Conclusion

Wire handles play an integral role in the manufacturing landscape, impacting various industries and enhancing product usability. Their lightweight and customizable nature make them a preferred choice for many applications, ensuring that they remain relevant in an ever-evolving market. As industries continue to demand more efficient and reliable carrying solutions, the importance of wire handles is set to grow, underscoring their value as an indispensable manufacturing component. With advancements in materials and technology, the future of wire handles looks promising, paving the way for innovative designs that cater to diverse manufacturing needs.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025