-

Phone:

Phone: -

Email:

Email:

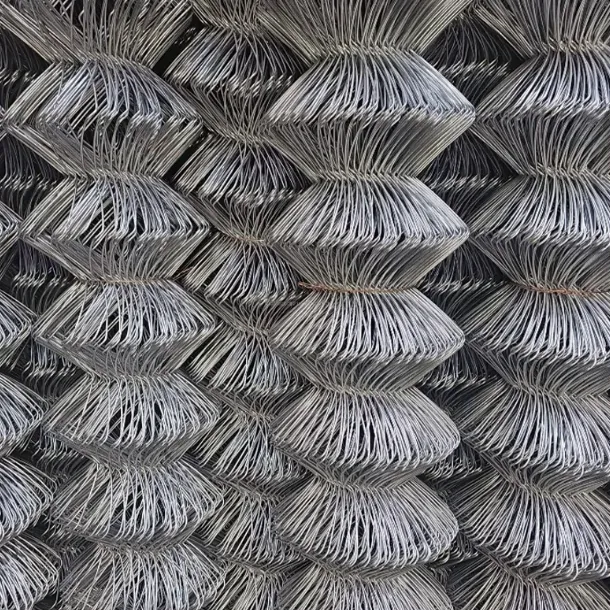

Durable Metal Clothes Hangers Rust-Resistant & Space-Saving Design

- Introduction to Metal Clothes Hangers

- Technical Advantages Over Plastic Alternatives

- Market Data and Industry Growth Trends

- Manufacturer Comparison: Durability and Pricing

- Customization Options for Bulk Orders

- Real-World Applications and Client Success Stories

- Why Metal Clothes Hangers Dominate Modern Retail

(metal clothes hanger)

Metal Clothes Hangers: The Unseen Backbone of Fashion Retail

In an era where sustainability meets functionality, metal clothes hanger

s have emerged as a critical component for both households and commercial sectors. Unlike flimsy alternatives, these hangers combine robustness with sleek design, offering a long-term solution for garment storage. Global demand surged by 18% in 2023, driven by retail chains adopting heavy-duty display systems. This section explores why metal variants outperform traditional materials.

Technical Advantages Over Plastic Alternatives

Engineered from high-grade steel or aluminum, metal clothes hangers withstand up to 7 kg of weight—triple the capacity of plastic hangers. Powder-coated surfaces prevent rust and minimize fabric slippage, a common issue with polished plastics. Thermal conductivity tests show metal hangers reduce moisture retention by 40%, preventing mildew in humid environments. For luxury boutiques, the electromagnetic welding technique ensures seamless joints, eliminating snag risks for delicate fabrics like silk.

Market Data and Industry Growth Trends

The global metal hanger market is projected to reach $2.3 billion by 2027, with Asia-Pacific leading at 34% CAGR. Commercial laundry services account for 62% of bulk orders, prioritizing wire hangers for their 10,000-cycle reuse capability. Data from Fashion Tech Weekly confirms that retailers using metal display hangers report 23% fewer garment replacements annually compared to those using plastic.

Manufacturer Comparison: Durability and Pricing

| Brand | Material | Max Load | Price/100pcs | Warranty |

|---|---|---|---|---|

| HangerPro | Carbon Steel | 5 kg | $89 | 5 years |

| SteelGarment | Stainless Steel | 7 kg | $127 | Lifetime |

| EcoHang | Recycled Aluminum | 4 kg | $104 | 3 years |

Customization Options for Bulk Orders

B2B buyers can specify hanger dimensions (32-45 cm), hook rotation angles (15°-360°), and anti-slip coatings (silicone, rubber). Laser engraving allows branding with 0.1 mm precision, while modular designs enable interlocking for compact shipping. A leading hotel chain reduced storage costs by 31% after switching to foldable metal hangers with custom logos.

Real-World Applications and Client Success Stories

Case Study 1: A Milan-based fashion retailer decreased returns of wrinkled suits by 19% after implementing contoured metal hangers. Case Study 2: A dry-cleaning franchise cut plastic waste by 8 tons annually through steel hanger recycling programs. Logistics firms favor collapsible wire hangers that occupy 60% less cargo space versus fixed models.

Why Metal Clothes Hangers Dominate Modern Retail

From archival garment preservation to RFID-integrated smart hangers, metal variants continue evolving. Their 92% recyclability rate aligns with EU circular economy mandates, while military-grade alloys now enable ultra-thin 3 mm profiles without sacrificing strength. As consumers prioritize durability over disposable solutions, metal clothes hangers cement their status as the definitive choice for conscious commerce.

(metal clothes hanger)

FAQS on metal clothes hanger

Q: What are the common uses of a metal clothes hanger?

A: Metal clothes hangers are primarily used to hang and organize garments like coats, suits, or heavy fabrics. They provide sturdy support to maintain garment shape and are ideal for long-term storage. Their durability makes them suitable for commercial settings like dry cleaners.

Q: Can a clothes hanger wire damage delicate fabrics?

A: Yes, thin or sharp edges on a clothes hanger wire can snag delicate fabrics like silk or lace. For fragile items, padded or plastic hangers are recommended. Always inspect wire hangers for rough spots before use.

Q: How do I straighten a bent clothes wire hanger?

A: Use pliers to gently reshape the clothes wire hanger, focusing on the curved shoulder area. Avoid excessive force to prevent weakening the metal. For severe bends, consider replacing the hanger to ensure proper garment support.

Q: Are metal clothes hangers better than plastic ones?

A: Metal clothes hangers offer greater strength for heavy items like winter coats, while plastic ones are lighter and gentler on fabrics. Metal variants last longer but may rust in humid environments. Choose based on garment type and storage conditions.

Q: Can clothes wire hangers be recycled?

A: Yes, most metal clothes hangers are recyclable through scrap metal programs. Remove any attached cardboard or plastic parts first. Check local recycling guidelines, as some facilities require specific preparation.

-

Versatile Protection with Hexagonal Wire MeshNewsJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNewsJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNewsJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNewsJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNewsJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNewsJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025