-

Phone:

Phone: -

Email:

Email:

Understanding the Importance of Wire Bales in Industry Applications

The Versatility of Wire Bales An Essential Resource

In the world of manufacturing and recycling, one term stands out for its significance bale of wire. These compact bundles of wire, created through the process of baling, serve a multitude of purposes across various industries. Whether it’s in construction, manufacturing, or recycling, wire bales are a staple resource that reflects both practicality and innovation.

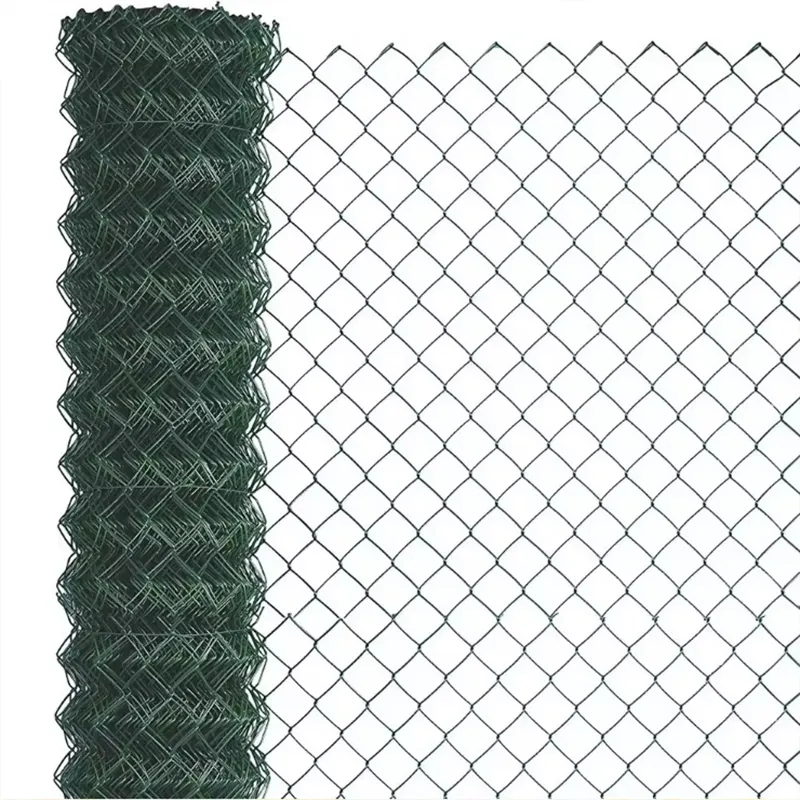

Wire bales are produced by compressing lengths of wire into dense, manageable bundles, often using specialized machinery. This process not only makes handling and transportation easier but also maximizes storage efficiency. Different types of wire can be baled, including scrap metal wire, fencing wire, and wire from various industrial applications. The most common types include steel wire, aluminum wire, and copper wire, each bringing its unique properties and applications.

One of the most significant advantages of baled wire is its role in the recycling industry. As concerns about environmental sustainability grow, the importance of recycling has never been more critical. Baled wire, particularly scrap metal wire, can be efficiently transported to recycling facilities where it is melted down and repurposed. This process reduces the demand for virgin materials, conserves resources, and lowers energy consumption. Moreover, recycling wire contributes to reducing waste in landfills, thus supporting a more sustainable future.

bale of wire

In construction and manufacturing, wire bales are essential for various applications. Steel wire, known for its strength and durability, is often used in concrete reinforcement. Baled wire can easily be transported to job sites, where it is utilized for tasks ranging from fabricating metal components to constructing wire frames. The versatility of wire allows for creativity and innovation in design, making it an invaluable resource across industries.

Another area where wire bales find their utility is in agriculture. Farmers often use baled wire for fencing, livestock management, and even trellising plants. Fencing wire, when baled, provides farmers with a convenient solution for protecting their crops and livestock from external threats. Additionally, the use of wire for supporting plants promotes healthier growth and increased yield.

As we move toward a more technological future, the manufacture and usage of wire bales are also evolving. With advancements in recycling technology and manufacturing processes, the efficiency and sustainability of wire production are improving. Innovations such as automated baling systems and environmentally friendly wire coatings are redefining the norms of traditional wire production.

In conclusion, the bale of wire is a seemingly simple yet remarkably versatile resource. From its crucial role in recycling and its applications in construction and agriculture to its ongoing adaptation in response to technological advancements, wire bales symbolize the intersection of utility and environmental responsibility. As industries continue to evolve, wire bales will undoubtedly remain a fundamental resource, proving that even the most ordinary materials can have a substantial impact on our world. Embracing such resources allows for a more sustainable and innovative future.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025