-

Phone:

Phone: -

Email:

Email:

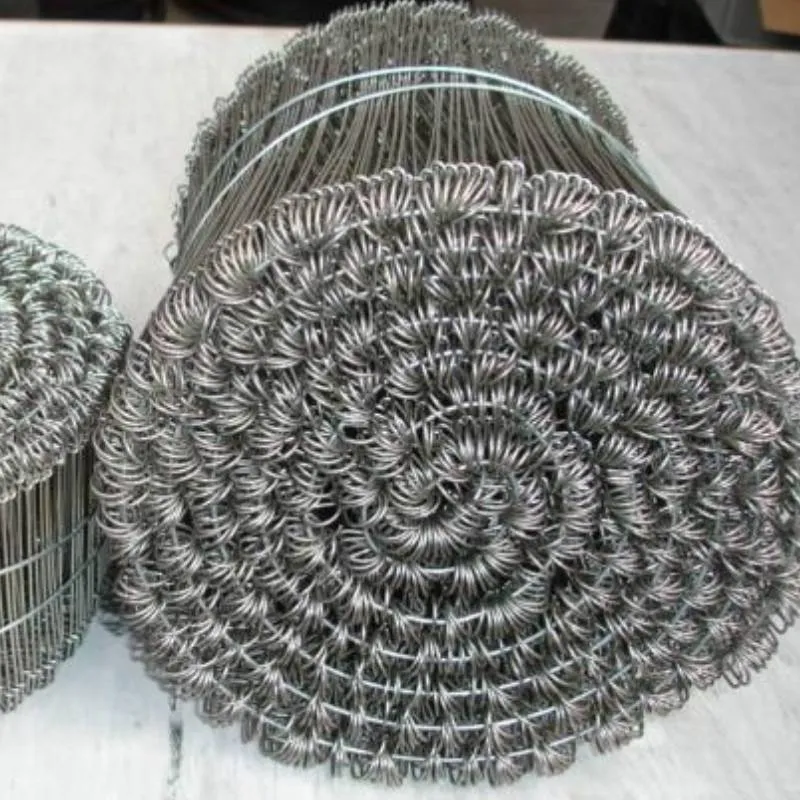

bale of wire

The Versatility of Wire Bales in Modern Applications

In our increasingly interconnected world, the materials we choose for construction, manufacturing, and even artistic endeavors often reflect the trends and technologies of the times. One such material that has remained reliable and versatile throughout various industries is wire, specifically in the form of bales.

A bale of wire typically refers to a tightly compressed bundle of wire, usually made from steel or other metals, which can be utilized in numerous applications. These wire bales are produced through a process of cutting, coiling, and binding, often resulting in a convenient and manageable size that facilitates handling and transport. While the appearance may be unassuming, the applications of wire bales are vast and impactful.

Construction and Infrastructure

One of the primary uses for wire bales is in the construction industry. High tensile steel wire, often found in these bales, plays a critical role in reinforcing concrete structures. This type of wire is vital for ensuring that buildings, bridges, and other infrastructures can withstand significant loads, strains, and stresses over time. Reinforced concrete offers improved durability, ultimately leading to safer and longer-lasting structures.

Moreover, wire bales are often used in creating mesh panels that are crucial for building enclosures and fencing. These panels can be found in various forms, from agricultural fencing protecting livestock to industrial applications securing sensitive areas. The strength of the wire ensures that these enclosures are robust and effective, maintaining their integrity regardless of external pressures.

Manufacturing Industries

Beyond construction, wire bales are integral to many manufacturing sectors. They are used extensively in the production of various wire products, including nails, fasteners, and other essential components. The manufacturing process typically requires large quantities of wire, making the bundled form of wire bales not only practical but also efficient for producers.

In the electronics sector, wire bales provide the necessary materials for the production of conductive wiring used in countless devices. The demand for high-quality wire is ever-present, especially as technology proliferates, and the need for reliable electrical connectors and circuitry increases.

bale of wire

Agricultural Applications

In agriculture, wire bales serve as a fundamental resource for farmers and ranchers globally. The wires are often used for constructing fences that keep livestock safe and contained. Barbed wire, for instance, is a widely used form of wire in agricultural fencing that effectively deters animals from crossing boundaries.

Furthermore, wire is essential in supporting crops. Trellis systems, which allow climbing plants such as tomatoes and cucumbers to grow, are constructed using wire bales. These supports not only maximize space but also improve air circulation among the plants, leading to healthier crops.

Artistic and Creative Endeavors

Interestingly, wire bales have also found their way into the realm of arts and crafts. Artists and creative individuals appreciate the malleability and durability of wire, using it to create intricate sculptures and installations. The ability to manipulate wire allows for the expression of complex forms and structures, embodying both simplicity and intricate detail.

Workshops where individuals learn to create wire art have emerged, showcasing the unique applications that this material can provide, often leading to community engagement and fostering creativity.

Conclusion

The bale of wire may seem like a simple product, yet its applications are multifaceted and vital across numerous industries. Whether reinforcing a skyscraper, manufacturing essential components, supporting agricultural practices, or igniting creativity in the arts, wire bales display a remarkable versatility and sustainability. As we continue to innovate and adapt, the importance of such materials will only grow, ensuring their place in our modern world. Embracing the utility of wire bales not only reflects appreciation for traditional materials but also highlights the endless possibilities they present for future developments.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025