-

Phone:

Phone: -

Email:

Email:

Innovative Solutions for Efficient Bale Wire Management and Recycling Practices

Understanding Bale Wire Its Importance and Applications

Bale wire is a specialized metal wire used primarily in the agricultural and recycling industries to bind bales of crops or various recyclable materials. The significance of bale wire cannot be understated, as it plays a crucial role in preserving the quality of products, enhancing logistical efficiency, and maintaining organization in storage. This article delves into the various aspects of bale wire, including its types, applications, and benefits.

Types of Bale Wire

There are different types of bale wire available in the market, each designed for specific purposes. The most common materials used for bale wire include steel and polypropylene.

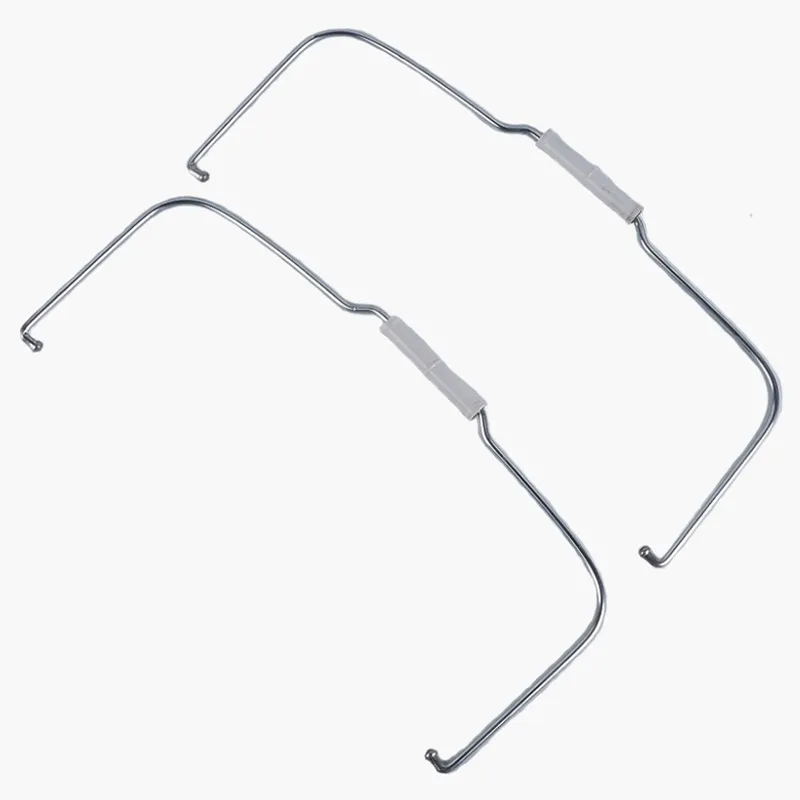

1. Steel Bale Wire This is the most commonly used type of bale wire. Galvanized steel wire is resilient, ensuring that bales remain secure during transportation and storage. This type of wire is often used for binding hay, straw, and other agricultural products. Its strength and durability make it well-suited for heavy loads, and the galvanized coating offers protection against rust, thereby prolonging its usability.

2. Polypropylene Bale Wire This variant is made of synthetic materials and is lighter than its steel counterpart. It is often used in the recycling industry and for binding lightweight materials like plastics and paper. Polypropylene bale wire is resistant to moisture and does not rust, making it an ideal choice for applications where moisture exposure is a concern.

3. Twisted and Straight Bale Wire Bale wire also comes in different forms. Twisted wire is typically stronger and more prone to holding a tight bind compared to straight wire. While twisted wire is often favored in agricultural applications, straight wire is usually sufficient for lighter or less demanding tasks.

Applications of Bale Wire

The primary use of bale wire is in agriculture, where it is essential for bundling crops like hay, cotton, and straw into compact bales that can be easily transported and stored. The secure binding provided by bale wire prevents bales from falling apart, which can lead to loss of product quality and increased labor during handling.

bale wire

In the recycling industry, bale wire is equally crucial. It helps create compact bales of recyclable materials, including plastics, paper, and metals. These bales are easier to transport and store, making recycling operations more efficient. By binding materials together, bale wire minimizes space requirements in recycling facilities and helps maintain order, ensuring that different materials are separated for effective processing.

The Benefits of Using Bale Wire

Using bale wire offers numerous benefits to farmers, recyclers, and businesses alike. Some of these benefits include

1. Enhanced Storage Efficiency By binding materials into compact bales, bale wire reduces the amount of storage space required. This feature is particularly advantageous for businesses that have limited warehouse space.

2. Improved Transportation Bales that are securely bound with bale wire are easier to transport. They can be loaded onto trucks or transported using forklifts without the risk of falling apart, which reduces the likelihood of damage during transit.

3. Cost Effectiveness While investing in high-quality bale wire incurs an initial cost, the long-term benefits in efficiency, reduced product loss, and improved logistics often outweigh the expenses.

4. Environmental Impact In the recycling industry, the use of bale wire helps facilitate better recycling practices, reducing waste and promoting a circular economy.

Conclusion

Bale wire is a vital component in both agriculture and recycling sectors. Its ability to securely bind materials together not only preserves the integrity of products but also enhances logistical efficiency in storage and transportation. By understanding the various types of bale wire and their applications, stakeholders can make informed decisions that maximize productivity and sustainability in their operations. Whether you are a farmer looking to secure your harvest or a recycler aiming to optimize your material processing, bale wire remains an indispensable tool in achieving your goals.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025