-

Phone:

Phone: -

Email:

Email:

Cost Analysis of Baling Wire for Efficient Packaging Solutions

Understanding Baling Wire Costs An Essential Component in Recycling and Waste Management

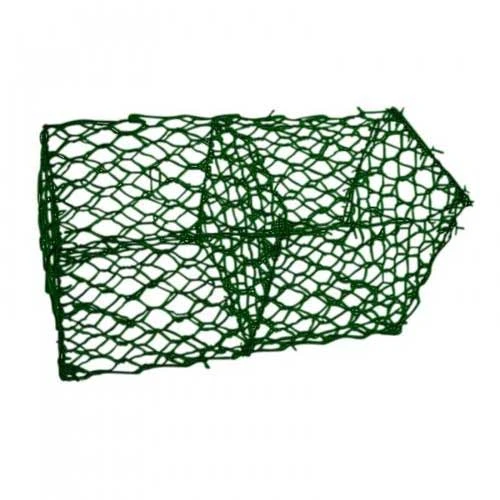

Baling wire is a critical component used in various industries, particularly in recycling and waste management. This robust wire is essential for bundling materials such as cardboard, paper, plastic, and metals into compact bales, making them easier to handle, transport, and process. Given its importance, understanding the factors influencing baling wire costs is vital for businesses striving for efficiency and profitability.

One primary factor affecting baling wire costs is the type of wire used. Baling wire comes in various materials, including steel, stainless steel, and polypropylene. Steel baling wire is the most commonly used due to its strength and durability, but it may come at a higher cost than alternatives. The specific needs of the application, including the type of materials being bundled and the required strength of the wire, will determine which type is most appropriate and cost-effective.

Market fluctuations significantly influence baling wire prices. The cost of raw materials, particularly steel, varies based on supply and demand dynamics in the global marketplace. Periods of high demand, such as economic booms or increased levels of recycling activities, can lead to spikes in steel prices, consequently driving up the cost of baling wire. Conversely, during economic downturns, prices may stabilize or decrease.

baling wire cost

Another critical aspect to consider is the length and gauge of the baling wire. Thicker gauges typically offer more strength and durability, critical for heavy materials, but also increase the overall cost. The length of the wire is also a consideration, as longer lengths may be more economical but require careful planning in order to minimize waste.

Additionally, purchasing practices can impact costs. Buying in bulk often results in a lower per-unit price, making it a preferable option for businesses that require large quantities of baling wire regularly. Establishing relationships with suppliers and negotiating contracts can lead to favorable pricing agreements.

Ultimately, balancing quality and cost is crucial for businesses relying on baling wire. By understanding the factors affecting its price, companies can make informed decisions that enhance their operational efficiency while managing costs effectively. As the recycling industry continues to grow, keeping a close eye on baling wire costs will remain a priority for those looking to optimize their processes and maintain competitive in the marketplace.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025