-

Phone:

Phone: -

Email:

Email:

Feb . 10, 2025 20:01

Back to list

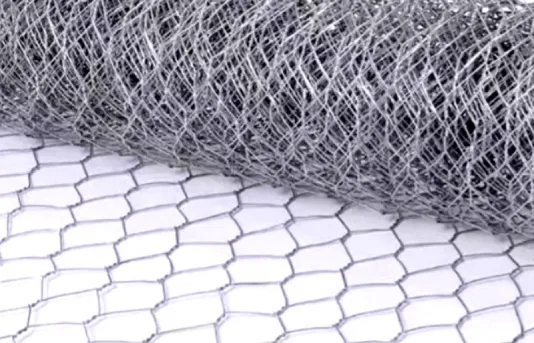

Baling Wire

In the realm of industrial packaging, baling wire manufacturers play a crucial role in ensuring the seamless bundling and transportation of various materials. Baling wire, though seemingly simple, is a backbone component used extensively across recycling centers, agribusinesses, and manufacturing facilities. Here, we delve into the world of baling wire manufacturing, shedding light on the intricacies that make a producer stand out in this competitive market.

Furthermore, customer experience is greatly enhanced when manufacturers offer personalized solutions. Instead of opting for a one-size-fits-all approach, leading companies offer custom wire sizes and finishes, catering to the specific needs of their clients. This flexibility not only addresses the unique challenges of different sectors but also demonstrates a commitment to service excellence. Manufacturers also distinguish themselves through efficient logistics and support systems. Given that baling operations often require continuous supply, timely delivery is critical. From rigorous inventory management to a robust distribution network, successful manufacturers ensure their products are readily accessible to clients globally. Lastly, sustainability is an emerging focus within the industry. The best manufacturers are those who are proactively reducing their carbon footprint by optimizing their production processes and exploring eco-friendly packaging options. By aligning with sustainability goals, these companies not only appeal to environmentally-conscious clients but also contribute positively to global ecological efforts. In summary, the baling wire manufacturing industry is defined by a blend of innovative expertise, strict adherence to quality standards, and an unwavering commitment to customer satisfaction. The manufacturers at the forefront are those who continuously push the boundaries of material science, maintain transparent operations, and align their services with the evolving needs of the market. For businesses relying on baling solutions, partnering with a reputable and forward-thinking manufacturer is a step towards ensuring efficiency and reliability in their operations.

Furthermore, customer experience is greatly enhanced when manufacturers offer personalized solutions. Instead of opting for a one-size-fits-all approach, leading companies offer custom wire sizes and finishes, catering to the specific needs of their clients. This flexibility not only addresses the unique challenges of different sectors but also demonstrates a commitment to service excellence. Manufacturers also distinguish themselves through efficient logistics and support systems. Given that baling operations often require continuous supply, timely delivery is critical. From rigorous inventory management to a robust distribution network, successful manufacturers ensure their products are readily accessible to clients globally. Lastly, sustainability is an emerging focus within the industry. The best manufacturers are those who are proactively reducing their carbon footprint by optimizing their production processes and exploring eco-friendly packaging options. By aligning with sustainability goals, these companies not only appeal to environmentally-conscious clients but also contribute positively to global ecological efforts. In summary, the baling wire manufacturing industry is defined by a blend of innovative expertise, strict adherence to quality standards, and an unwavering commitment to customer satisfaction. The manufacturers at the forefront are those who continuously push the boundaries of material science, maintain transparent operations, and align their services with the evolving needs of the market. For businesses relying on baling solutions, partnering with a reputable and forward-thinking manufacturer is a step towards ensuring efficiency and reliability in their operations.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS