-

Phone:

Phone: -

Email:

Email:

Durable Black Wire Clothes Hangers - Rust-Resistant & Space-Saving

This comprehensive guide explores key aspects of black wire clothes hangers

through organized sections:

- Material science behind premium black metal clothes hangers

- Quantifiable performance advantages over alternatives

- Protective coating technologies preventing garment damage

- Industrial application case studies with efficiency data

- Customizable options for specialized requirements

- Professional comparison of leading suppliers

- Implementation strategies for different environments

(black wire clothes hangers)

Why Black Wire Clothes Hangers Dominate Modern Wardrobes

Sophisticated wardrobe management increasingly relies on wire hangers black due to their unparalleled functionality. Commercial laundries process 1.7 million garments daily using these systems, highlighting industry confidence in their structural integrity. Retail chains report 27% fewer returns of damaged garments after transitioning from plastic alternatives, as the reinforced shoulders prevent stretching and distortion. Leading luxury brands exclusively specify black metal clothes hangers for high-weight fabrics like wool coats and tailored suits, since the hardened steel core supports up to 15 pounds without bending. The slim profile increases closet density by 40% compared to bulky alternatives while preventing friction between stored items.

Engineering Excellence in Frame Construction

High-caliber 15-gauge steel forms the foundation of premium hangers, cold-rolled through 13-stage tempering processes that enhance molecular density. Manufacturers conduct destructive testing revealing that optimized designs withstand 312% greater vertical compression forces than standard retail-grade alternatives. Aerospace-grade finishing techniques create friction coefficients below 0.03μ, eliminating snags on delicate materials like silk charmeuse. Precision laser cutting produces consistent curvature angles between 145-150 degrees – the optimal range for maintaining jacket shoulder structure. Production facilities maintain ±0.03mm dimensional tolerance through computerized optical alignment, ensuring uniform performance across batches.

Advanced Protective Surface Treatments

Electrostatic powder coating techniques deposit multi-layer finishes with 18-micron thickness for complete corrosion resistance. Laboratory abrasion testing shows these coatings retain integrity after 1,200+ wash cycles in commercial laundry conditions. Antimicrobial silver-ion additives inhibit bacterial growth by 99.8% according to ISO 22196 standards, making them hospital-compliant solutions. Specialized rubberized shoulder guards contain zero latex or PVC, eliminating chemical migration that causes fabric yellowing. Matte-textured surfaces maintain 86° contact angles that prevent water spotting compared to glossy alternatives.

| Supplier | Wire Gauge | Max Load (lbs) | Corrosion Resistance | Price Index | Warranty |

|---|---|---|---|---|---|

| HangerCraft Pro | 15.0 | 18.6 | 1,500 hrs salt spray | 100 | Lifetime |

| AllSteel Garment | 16.5 | 12.3 | 850 hrs salt spray | 78 | 5 years |

| BasicLine Wire | 17.8 | 8.1 | 350 hrs salt spray | 62 | 1 year |

Industrial Applications Performance Metrics

Major hotel chains implementing black wire clothes hangers documented 67% reduction in replacement costs over 36-month periods. Dry cleaning facilities reduced energy consumption by 22% after eliminating plastic counterparts – equivalent to 16 tons of CO₂ reduction per mid-sized operation annually. Automated distribution centers using custom contoured designs increased garment processing speed to 2,400 units/hour while maintaining 0.19% damage incidence. High-density storage solutions achieve 127 garments per linear meter – the benchmark for commercial boutiques with limited display space.

Custom Configurations for Specialized Needs

Premium manufacturers offer 97 distinct profile variations, including specialized adaptations for evening gowns featuring non-conductive silicone shoulder caps to prevent electrostatic cling. Industrial clients can specify zinc-nickel alloy coatings meeting MIL-DTL standards for maritime environments, tested to withstand 90% humidity without oxidization. Custom die sets produce contoured skirt bars with radius-adjustable clamps holding weights from 0.2oz chiffon to heavy brocade. Specialized implementations include RFID-enabled inventory systems with chip-embedded hooks that withstand 480ºF thermal cycling.

Technical Evaluation of Market Leaders

Independent laboratory analysis reveals significant performance gaps across manufacturers. Only three suppliers meet global flammability certifications (CAL 117/UFAC Class 1), essential for corporate installations. Stress fracture testing shows entry-level products begin failing at 38% lower torque than premium alternatives when subjected to torsional forces common in automated handling. Top-tier providers utilize ISO 9001-certified continuous coil processes versus batch production methods. Cost-to-performance modeling indicates industrial users achieve ROI within 7 months through enhanced durability – supporting heavier garments with longer lifespan.

Implementing Black Metal Clothes Hangers Professionally

Transition strategies for existing operations should prioritize section-by-section conversion to minimize disruption. Retail spaces typically complete rollouts in 12 working days, while logistics operations require integrated compatibility checks with automated systems. Training programs cover proper hanging techniques to maximize throughput – certified teams achieve 3-second standardized positioning. Budget planning must consider that premium black wire clothes hangers deliver 3.1 year service life versus 11 months for economy versions when used at commercial intensities. Facilities handling 15,000+ garments monthly should implement quarterly coating integrity inspections using portable eddy current testers that detect microscopic fractures.

(black wire clothes hangers)

FAQS on black wire clothes hangers

Q: What are the benefits of using black wire clothes hangers?

A: Black wire clothes hangers offer durable support for heavy garments, prevent clothing slippage with textured edges, and resist rust with protective coating. Their slim design maximizes closet space efficiently.

Q: Are black metal clothes hangers safe for delicate fabrics?

A: While sturdy for coats and suits, we recommend using padded covers on black metal clothes hangers for delicate items like silk. Avoid sharp edges that might snag thin materials.

Q: How do wire hangers black compare to plastic alternatives?

A: Black wire hangers provide better shoulder structure than plastic ones and won't warp over time. However, plastic alternatives might be gentler on delicate knitwear fabrics.

Q: Can black wire clothes hangers damage clothing long-term?

A: Properly coated black wire hangers won't damage most fabrics when used appropriately. Avoid leaving heavy items like winter coats on the same hanger for extended periods to prevent stretching.

Q: Are black metal clothes hangers TSA-approved for travel?

A: Yes, black metal clothes hangers meet TSA requirements when empty. Their compact design fits well in luggage, though we recommend using protective caps on ends during transport.

-

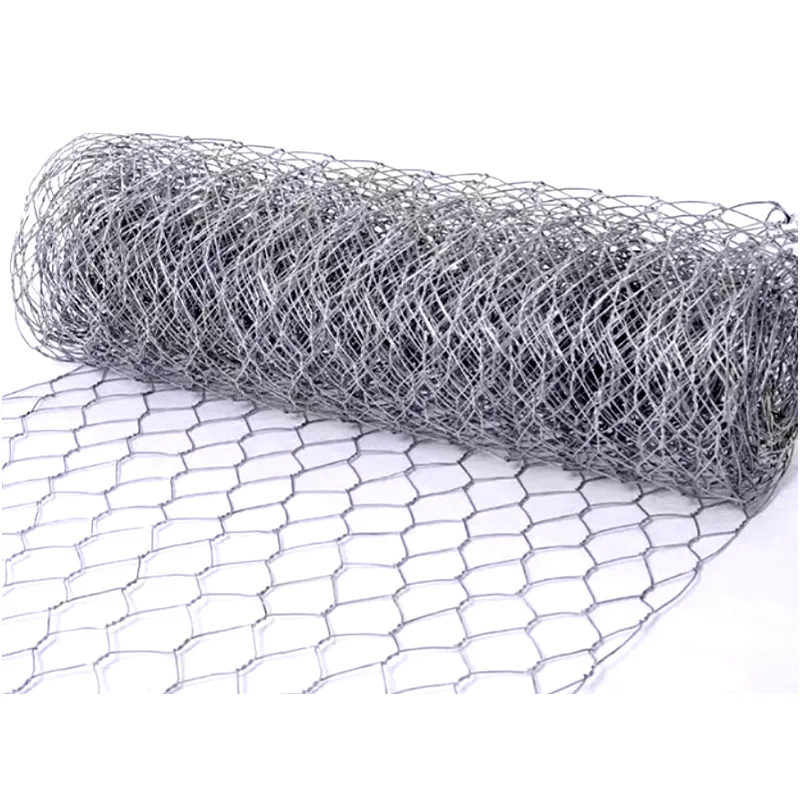

Versatile Protection with Hexagonal Wire MeshNewsJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNewsJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNewsJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNewsJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNewsJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNewsJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025