-

Phone:

Phone: -

Email:

Email:

How to Choose the Best Baling Wire for Your Needs

Understanding the Importance of Buying Baling Wire for Your Business

In today's fast-paced industrial environment, the efficient handling and processing of materials is paramount. One critical component that plays a significant role in this process is baling wire. Whether you are in the recycling industry, agriculture, or manufacturing, understanding the purpose and advantages of investing in high-quality baling wire can greatly enhance your operational efficiency and product quality.

What is Baling Wire?

Baling wire is a type of wire used to bind or secure materials into bales. These bales could be composed of various materials, such as cardboard, paper, textiles, or agricultural products like hay and straw. Baling wire is typically made from steel or other durable materials and comes in different sizes and thicknesses, depending on the application.

The Need for Baling Wire

Baling is a crucial process for several industries. It reduces the volume of waste materials, making it easier to handle, transport, and store them. For example, in the recycling sector, baling wire is used to compress recyclables into compact bales, promoting greater efficiency in shipping and processing. Purchasing the right baling wire is essential, as it ensures the integrity of the bales and prevents any materials from spilling or becoming damaged during transit.

In agriculture, baling wire is used to bundle hay or straw, allowing farmers to transport feed easily or store it without the risk of spoilage. This versatility highlights the necessity of quality baling wire across various sectors.

Factors to Consider When Buying Baling Wire

buy baling wire

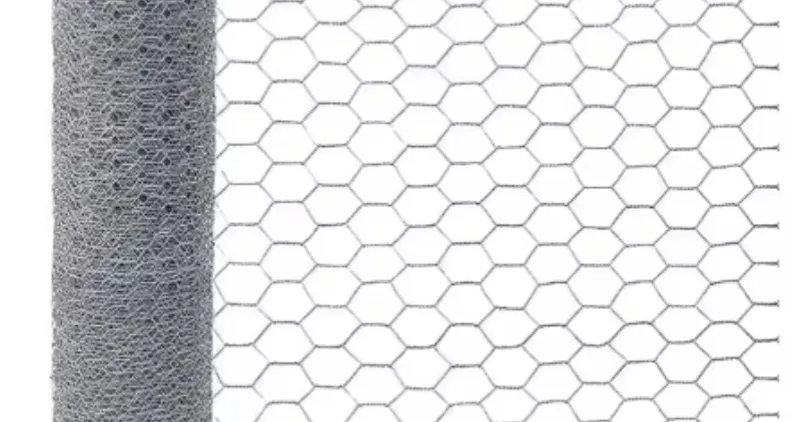

1. Material Quality The material from which the baling wire is made is critical. Steel wire is a popular option due to its strength and durability. Galvanized wire, which has a protective zinc coating, is an excellent choice for outdoor applications as it resists rust and corrosion.

2. Thickness and Diameter Different applications require different thicknesses and diameters of baling wire. Heavier materials may need thicker wire to ensure secure binding, while lighter applications can utilize thinner options. It's essential to select the wire that best fits the bales you are handling.

3. Coil Size Baling wire typically comes in coils, and the size of the coil can affect how often you need to restock. Larger coils may reduce the frequency of ordering but can be cumbersome to handle. Consider your operational needs when deciding on coil size.

4. Supplier Reputation When purchasing baling wire, it's beneficial to buy from reputable suppliers. Research their product quality, read customer reviews, and ask about their return policy. A reliable supplier can provide you with high-quality materials that improve your overall operational efficiency.

5. Cost-Effectiveness While it’s important to find a good deal, the cheapest option is not always the best. Evaluate the cost in relation to the quality and performance of the wire. Investing in higher-quality baling wire can save you money in the long run by reducing waste and improving productivity.

Conclusion

In conclusion, buying the right baling wire is a fundamental consideration for businesses involved in material handling and processing. Understanding the various options available and the factors that influence your decision will ultimately contribute to your operational success. Whether for recycling, agriculture, or manufacturing, investing in high-quality baling wire assures you of safe, efficient, and effective material management. By prioritizing quality and reliability, you not only enhance your workflows but also ensure that your end products meet the expected standards. Make informed choices, and watch your operations thrive as a result.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025