-

Phone:

Phone: -

Email:

Email:

cable cu xlpe swa pvc

The Significance of Cable Construction Understanding CU XLPE SWA PVC Cables

In the world of electrical engineering and installation, cables are the lifeline of energy distribution. Among the plethora of options available, CU XLPE SWA PVC cables stand out due to their versatile applications and robust constructions. To better appreciate the significance of these cables, it is essential to decipher the meaning of each component in their nomenclature.

Copper Conductors (CU) The CU in CU XLPE SWA PVC signifies that the cable’s conductors are made of copper. Copper is known for its excellent electrical conductivity, making it a preferred material in cable construction. It enhances efficiency by minimizing energy loss during transmission. Additionally, copper’s flexibility allows for ease of installation in various environments, making it suitable for residential, commercial, and industrial applications.

Cross-Linked Polyethylene (XLPE) XLPE refers to cross-linked polyethylene, a type of insulation that provides remarkable thermal resistance. Unlike traditional polyethylene insulation, which can soften at high temperatures, XLPE maintains its integrity even under elevated heat. This property is crucial in preventing cable deterioration and ensuring prolonged lifespan, especially in high-load systems. The enhanced thermal performance of XLPE also means that the cables can carry more current safely, reducing the risk of overheating.

The Significance of Cable Construction Understanding CU XLPE SWA PVC Cables

Polyvinyl Chloride (PVC) Finally, PVC denotes the use of polyvinyl chloride as an outer sheath material for the cable. PVC is known for its durability and resistance to chemicals, moisture, and UV rays. This protective outer layer is essential for safeguarding the internal components of the cable from external environmental factors, thereby enhancing its longevity. PVC cables are also lightweight and flexible, making them easier to handle and install compared to other materials.

cable cu xlpe swa pvc

Applications and Advantages

CU XLPE SWA PVC cables are widely used in various sectors, including industrial plants, power generation, and distribution networks. Their robust construction makes them suitable for both indoor and outdoor applications. These cables can be buried underground, installed in cable trays, or used in environments where humidity and chemicals are present.

The advantages of using CU XLPE SWA PVC cables extend beyond just their physical characteristics. Their capability to handle higher loads without overheating allows for improved performance in energy distribution systems. The combination of copper conductors with XLPE insulation also results in lower voltage drops, which is critical for maintaining efficiency in electrical networks.

Furthermore, the steel wire armor provides added peace of mind regarding the cable’s durability, especially in high-stress scenarios. Since electricity usage continues to grow across various sectors, having a reliable and efficient cable solution like CU XLPE SWA PVC becomes increasingly important.

Conclusion

In conclusion, CU XLPE SWA PVC cables represent a blend of advanced materials and engineering that address the needs of modern electrical systems. Their robust construction and versatile applications make them a preferred choice for many engineers and electricians. As we continue to innovate and expand our energy needs, understanding such cable types will be crucial in making informed decisions for electrical installations and infrastructure. Whether for industrial, commercial, or residential use, CU XLPE SWA PVC cables offer reliability and performance, ensuring that our energy needs are met safely and efficiently.

-

Metal Products Company Galvanized Cable for SaleNewsAug.06,2025

-

Maintenance of Rock Wall with Wire MeshNewsAug.06,2025

-

Loop Tie Wire Cost Effective OptionsNewsAug.06,2025

-

High Quality Cable Cu Xlpe Swa Pvc SupplyNewsAug.06,2025

-

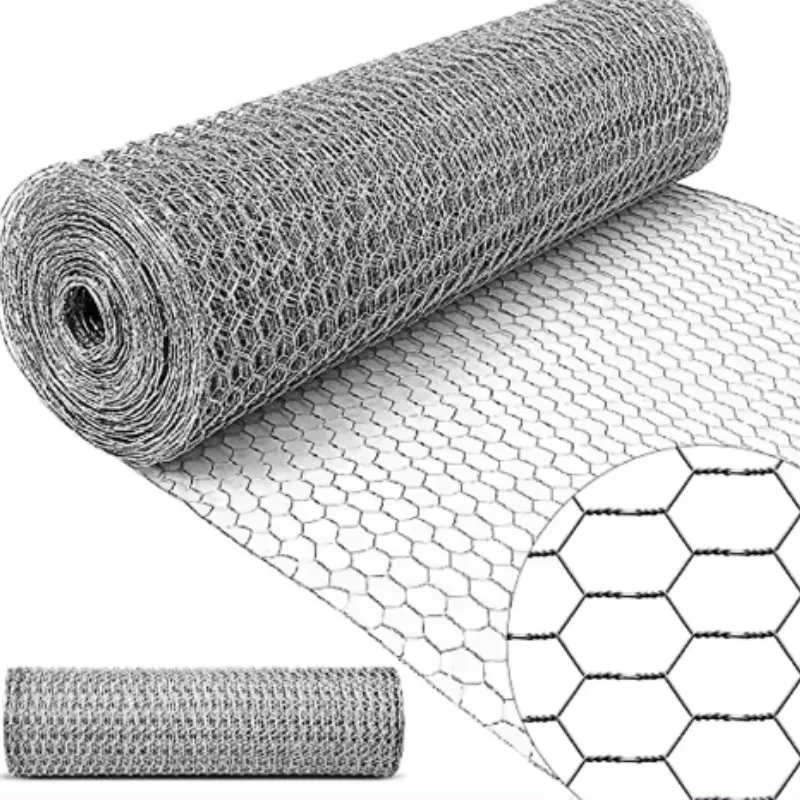

Durable Hexagonal Mesh Wire ProductsNewsAug.06,2025

-

Baling Wire Direct Reliable ServiceNewsAug.06,2025

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025