-

Phone:

Phone: -

Email:

Email:

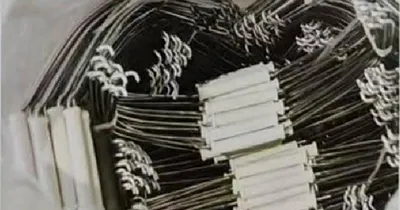

Choosing the Right Baling Wire Gauge for Your Project A Comprehensive Guide

Baling wire gauge refers to the thickness of baling wire, which is a type of sturdy wire used for baling or tying items together. Baling wire is commonly used in industries such as agriculture, recycling, and waste management to secure bales of material for transportation and storage. The gauge of baling wire is an important factor to consider when selecting the appropriate wire for a specific application.

The gauge of baling wire is typically measured in terms of its diameter in inches or millimeters. The higher the gauge number, the thinner the wire will be. For example, a baling wire with a gauge of 16 is thicker than a baling wire with a gauge of 20. The gauge of baling wire can range from as low as 10 to as high as 18, with different gauges being suitable for different applications.

When determining the appropriate baling wire gauge for a specific application, several factors should be taken into consideration. These factors include the weight and density of the material being baled, the size and shape of the bales, and the method of baling or tying. For example, heavier materials such as scrap metal or dense plastics may require a thicker gauge of baling wire to provide sufficient strength and durability.

baling wire gauge

In addition to the gauge of the wire, the tensile strength of the wire is also an important consideration. Tensile strength refers to the maximum amount of stress or force that a wire can withstand before breaking. Baling wire with a higher tensile strength is more durable and less likely to break under pressure, making it ideal for heavy-duty applications.

Another important factor to consider when selecting baling wire is the coating or finish of the wire. Some baling wires are galvanized or coated with a protective material to prevent rust and corrosion, which can prolong the lifespan of the wire and enhance its performance in outdoor or high-moisture environments.

Overall, the gauge of baling wire plays a crucial role in the effectiveness and durability of baling applications. By selecting the appropriate gauge of baling wire based on factors such as material weight, tensile strength, and coating, industries can ensure the secure and reliable baling of materials for transportation, storage, and recycling purposes.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025