-

Phone:

Phone: -

Email:

Email:

Mar . 06, 2025 11:05

Back to list

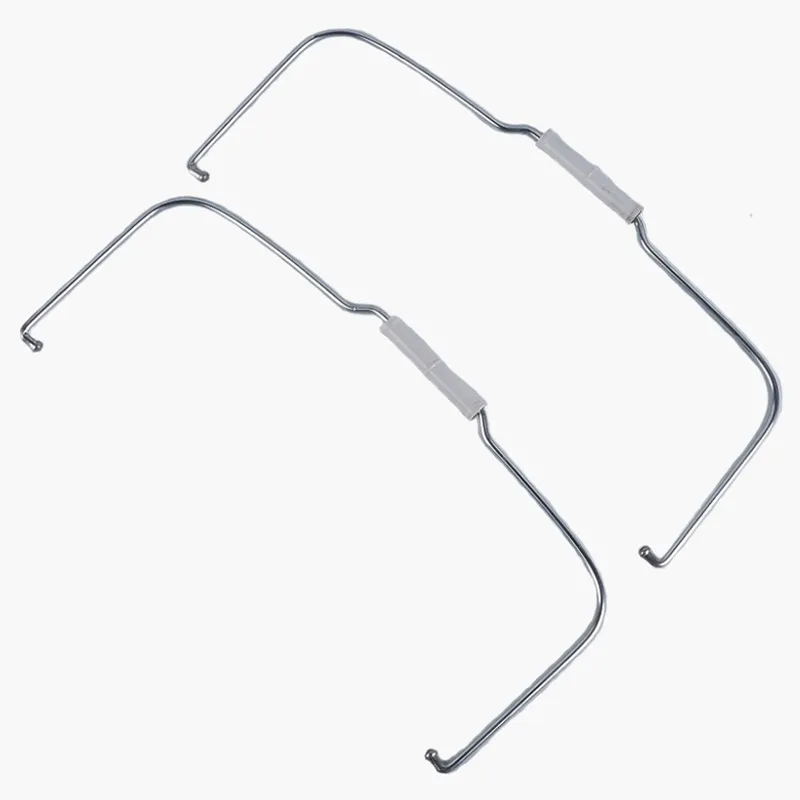

clothes hanger wire gauge

Selecting the right wire gauge for clothes hangers might seem trivial, yet it significantly impacts the functionality and durability of the product. A wire's gauge is paramount for anyone seeking the perfect balance between strength, flexibility, and weight capacity in hangers, commonly used in both personal wardrobes and retail environments. To ensure you make informed decisions, it’s crucial to understand the technicalities of wire gauge and its implications on clothes hangers.

The selection of hanger wire gauge should also consider aesthetic elements and environmental impact. Thicker gauges can be coated with materials such as rubber or velvet, which adds a non-slip feature and enhances the visual appeal. Such enhancements are pivotal for boutiques where the presentation is key. Furthermore, thicker steel or aluminum gauges often come with protective coatings that lengthen their lifespan by resisting rust and corrosion, thereby reducing environmental waste and promoting sustainability. Experts in the field also highlight the importance of testing wire gauge strength with specific weight requirements. A precise assessment helps in selecting hangers tailored to specialized garment collections, like evening wear or bespoke suits, which require unwavering support and immaculate condition. Professionals often rely on technical data sheets provided by manufacturers, which detail the load capacities and bending stress tolerances of various wire gauges. Such insights ensure that hanger selection aligns perfectly with the quality assurance policies in high-stake retail sectors. Trustworthiness in advice concerning wire gauge decisions comes from understanding both consumer needs and material science. Consulting with experts, referencing academic research on material properties, and evaluating consumer feedback are essential steps to authenticate claims about hanger durability and suitability. In conclusion, the choice of wire gauge in clothes hangers is a nuanced decision involving a balance of strength, utility, and aesthetics. While thin gauges offer lightweight and cost-effective solutions, thicker gauges provide superior resilience and longevity. A comprehensive understanding of wire gauge impacts, substantiated by expert analysis and empirical data, enables consumers and retailers to make prudent, informed choices in hanger selection. As wire gauge expertise becomes more prevalent, it not only enhances product quality but also fosters consumer confidence in the sustainability and effectiveness of hangers. This meticulous approach ensures that every gauge choice fulfills specific needs, maintaining both garment integrity and customer satisfaction.

The selection of hanger wire gauge should also consider aesthetic elements and environmental impact. Thicker gauges can be coated with materials such as rubber or velvet, which adds a non-slip feature and enhances the visual appeal. Such enhancements are pivotal for boutiques where the presentation is key. Furthermore, thicker steel or aluminum gauges often come with protective coatings that lengthen their lifespan by resisting rust and corrosion, thereby reducing environmental waste and promoting sustainability. Experts in the field also highlight the importance of testing wire gauge strength with specific weight requirements. A precise assessment helps in selecting hangers tailored to specialized garment collections, like evening wear or bespoke suits, which require unwavering support and immaculate condition. Professionals often rely on technical data sheets provided by manufacturers, which detail the load capacities and bending stress tolerances of various wire gauges. Such insights ensure that hanger selection aligns perfectly with the quality assurance policies in high-stake retail sectors. Trustworthiness in advice concerning wire gauge decisions comes from understanding both consumer needs and material science. Consulting with experts, referencing academic research on material properties, and evaluating consumer feedback are essential steps to authenticate claims about hanger durability and suitability. In conclusion, the choice of wire gauge in clothes hangers is a nuanced decision involving a balance of strength, utility, and aesthetics. While thin gauges offer lightweight and cost-effective solutions, thicker gauges provide superior resilience and longevity. A comprehensive understanding of wire gauge impacts, substantiated by expert analysis and empirical data, enables consumers and retailers to make prudent, informed choices in hanger selection. As wire gauge expertise becomes more prevalent, it not only enhances product quality but also fosters consumer confidence in the sustainability and effectiveness of hangers. This meticulous approach ensures that every gauge choice fulfills specific needs, maintaining both garment integrity and customer satisfaction.

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS