-

Phone:

Phone: -

Email:

Email:

concrete tie wire

Understanding Concrete Tie Wire An Essential Component in Construction

Concrete tie wire, often referred to simply as tie wire, is a crucial element in the construction and reinforcement of concrete structures. This malleable wire is primarily used in the construction industry to hold rebar in place and ensure the integrity of concrete forms. Understanding the role and properties of concrete tie wire helps in achieving stronger and more durable concrete structures.

What is Concrete Tie Wire?

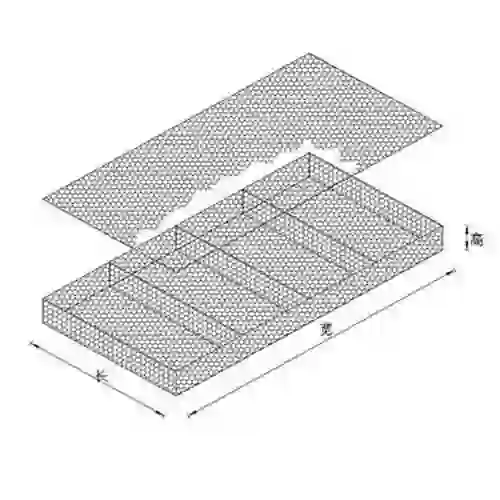

Concrete tie wire is typically made from steel and comes in various diameters, usually ranging from 16 to 20 gauge. Its unique properties make it an ideal choice for binding steel reinforcement bars (rebar) that are used to strengthen concrete. The wire is designed to be pliable yet strong enough to withstand the pressure and weight of concrete, which can be substantial during the curing process.

Applications of Concrete Tie Wire

The primary application of concrete tie wire is in the reinforcement of concrete. Workers use the wire to secure rebar in place before the concrete is poured. This ensures that the rebar remains in a fixed position, allowing for the proper distribution of stress and weight across the structure. By maintaining the spatial integrity of rebar, tie wire helps prevent the formation of cracks and ultimately contributes to the durability and longevity of concrete structures.

In addition to reinforcing bars, concrete tie wire is also commonly used to attach other components within a concrete formwork system

. It can be used to tie together various elements of the framework, ensuring that everything is held securely while the concrete sets. This is especially important in large projects where scaffolding and temporary supports play a crucial role in maintaining safety and structural integrity.Types of Concrete Tie Wire

concrete tie wire

There are different types of concrete tie wire available in the market, each suited for various applications. Some common types include

1. Annealed Tie Wire This type is soft and flexible, making it easy to twist and shape. It is the most common choice for general use in construction. 2. Galvanized Tie Wire This wire is coated with a layer of zinc to resist corrosion. It is particularly useful in environments where moisture is present, as it helps prevent rust that could weaken the wire over time.

3. Stainless Steel Tie Wire This option offers the highest resistance to corrosion, making it suitable for high-humidity areas or coastal regions where exposure to saltwater is a concern.

Benefits of Using Concrete Tie Wire

The use of concrete tie wire brings numerous advantages to construction projects. First and foremost, it enhances the structural integrity of concrete by ensuring that reinforcement bars are correctly positioned. By doing so, it helps in evenly distributing loads and minimizing stress concentrations.

Additionally, the affordability of tie wire makes it a popular choice among contractors. Its ease of use allows for quicker installation, which can save valuable time during the construction process. The lightweight nature of the wire also reduces transportation and handling costs on job sites.

Conclusion

In summary, concrete tie wire is an indispensable component in concrete construction and reinforcement. Its ability to securely hold rebar in place ensures that concrete structures are robust and durable. With various types available, including annealed, galvanized, and stainless steel options, contractors can choose the most suitable wire for their specific needs. As the construction industry continues to evolve, the importance of reliable materials like concrete tie wire remains a constant, underpinning the safety and longevity of buildings and infrastructure worldwide.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025