-

Phone:

Phone: -

Email:

Email:

Jan . 25, 2025 05:44

Back to list

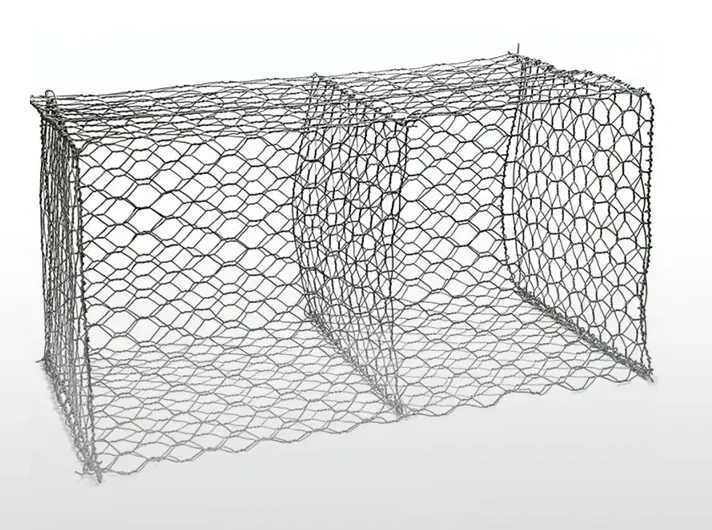

Loop Tie Wire

Concrete tie wire is an indispensable element within the construction industry, serving as the silent backbone that ensures structural integrity and longevity. For those working in the field of construction or infrastructure development, understanding the nuances of concrete tie wire is crucial to optimizing both process efficiency and structural outcomes. This informative piece sheds light on the vital attributes of concrete tie wire, backed by firsthand experiences, insightful expertise, and authoritative perspectives, aiming to bolster trust and reliability among professional practitioners.

The application of concrete tie wire extends beyond mere binding. It plays a crucial role in maintaining electrical continuity in structures requiring grounding systems. By effectively connecting various steel elements, it ensures that electrical conductivity is uniformly distributed, enhancing the safety and functionality of modern infrastructures. From an authoritative perspective, procurement of concrete tie wire should always be aligned with recognized industrial standards such as the ASTM A853 specification. Adherence to such standards guarantees that the wire meets the requisite criteria for quality, strength, and durability. This is of paramount importance in reinforcing the trustworthiness of the construction process and safeguarding the project's structural soundness. Trust in the utilization of concrete tie wire is fortified by decades of empirical research and practical application. Industry veterans emphasize the selection of reputable suppliers who can provide certified wire, meeting stringent quality assurances and supporting technical specifications. Such diligence in selection ensures that the wire not only performs under expected conditions but also withstands unforeseen environmental and mechanical stresses. In conclusion, concrete tie wire is more than just a binding tool; it is an essential component in the orchestration of durable and safe construction endeavors. Mastery in the use of concrete tie wire is cultivated through a blend of theoretical understanding and practical application, anchored in industry best practices. By prioritizing quality, understanding material properties, and adhering to standards, construction professionals can harness the full potential of concrete tie wire, ensuring that their projects achieve the pinnacle of structural integrity and resilience.

The application of concrete tie wire extends beyond mere binding. It plays a crucial role in maintaining electrical continuity in structures requiring grounding systems. By effectively connecting various steel elements, it ensures that electrical conductivity is uniformly distributed, enhancing the safety and functionality of modern infrastructures. From an authoritative perspective, procurement of concrete tie wire should always be aligned with recognized industrial standards such as the ASTM A853 specification. Adherence to such standards guarantees that the wire meets the requisite criteria for quality, strength, and durability. This is of paramount importance in reinforcing the trustworthiness of the construction process and safeguarding the project's structural soundness. Trust in the utilization of concrete tie wire is fortified by decades of empirical research and practical application. Industry veterans emphasize the selection of reputable suppliers who can provide certified wire, meeting stringent quality assurances and supporting technical specifications. Such diligence in selection ensures that the wire not only performs under expected conditions but also withstands unforeseen environmental and mechanical stresses. In conclusion, concrete tie wire is more than just a binding tool; it is an essential component in the orchestration of durable and safe construction endeavors. Mastery in the use of concrete tie wire is cultivated through a blend of theoretical understanding and practical application, anchored in industry best practices. By prioritizing quality, understanding material properties, and adhering to standards, construction professionals can harness the full potential of concrete tie wire, ensuring that their projects achieve the pinnacle of structural integrity and resilience.

Next:

Latest news

-

Metal Products Company Galvanized Cable for SaleNewsAug.06,2025

-

Maintenance of Rock Wall with Wire MeshNewsAug.06,2025

-

Loop Tie Wire Cost Effective OptionsNewsAug.06,2025

-

High Quality Cable Cu Xlpe Swa Pvc SupplyNewsAug.06,2025

-

Durable Hexagonal Mesh Wire ProductsNewsAug.06,2025

-

Baling Wire Direct Reliable ServiceNewsAug.06,2025

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

Related PRODUCTS