-

Phone:

Phone: -

Email:

Email:

Does rebar tie wire corrode when exposed to moisture and environmental conditions?

Does Rebar Tie Wire Rust? Understanding the Corrosion Resistance of Tie Wire in Construction

In the realm of construction, ensuring the longevity and durability of structures is paramount. One of the essential materials used in reinforcing concrete is rebar, or reinforcing bar, which is typically tied together with rebar tie wire. A common question that arises in construction practices is whether rebar tie wire rusts and, more importantly, how this may impact a construction project.

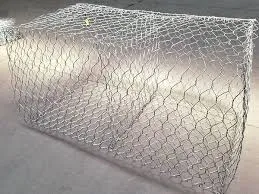

Rebar tie wire is designed specifically for securing rebar in place during the concrete pouring process. Typically made from various materials, including galvanized steel and stainless steel, the choice of material can significantly affect its susceptibility to rust and corrosion.

Understanding Rust and Corrosion

Rust is a form of corrosion that occurs when iron or its alloys (like steel) react with oxygen and moisture in the environment. This process leads to the formation of iron oxide, commonly known as rust, which can significantly weaken the metal over time. In construction, rust can compromise not only the integrity of the rebar but also the strength of the overall concrete structure, leading to costly repairs and potential safety hazards.

Factors Influencing Rust Formation in Tie Wire

1. Material Composition The type of material used in the rebar tie wire plays a critical role in its resistance to rust. While plain carbon steel tie wire is prone to rusting when exposed to moisture, galvanized tie wire, which is coated with a layer of zinc, offers added protection against corrosion. Stainless steel tie wire, known for its exceptional resistance to rust, is an even better choice in environments that are prone to moisture or the use of salt in de-icing applications.

does rebar tie wire rust

2. Environmental Conditions The likelihood of rebar tie wire rusting also depends heavily on the environmental conditions it is exposed to. High humidity, exposure to salty air (as found near coastlines), and the presence of chemicals can accelerate the corrosion process. In conditions where there is limited air circulation and high moisture retention, the risk of rust formation increases significantly.

3. Protective Measures Employing protective measures, such as using galvanized or stainless steel tie wire, can greatly reduce the risk of rust. Additionally, applying protective coatings to the rebar and tie wire can enhance durability and resistance to moisture, further extending the life of the construction materials.

The Importance of Choosing the Right Tie Wire

Choosing the right tie wire is essential for ensuring the durability of a constructed structure. While plain steel tie wire is often a more economical choice, its susceptibility to rust could lead to more significant problems down the line. In contrast, using galvanized or stainless steel tie wire may involve a higher initial cost but can save money in maintenance and repairs due to its resistance to corrosion.

For projects in areas with high moisture or salt exposure, it is advisable to opt for stainless steel tie wire, as its resistance to rust will ensure long-lasting performance and structural integrity. Furthermore, it is crucial for contractors and builders to perform regular inspections and maintenance on their projects to monitor signs of corrosion and take preemptive action.

Conclusion

In summary, the question of whether rebar tie wire rusts is one that hinges on several factors, including material choice, environmental conditions, and applicable protective measures. Understanding the nature of rust and developing a proactive approach to using tie wire can help ensure the longevity and safety of construction projects. Maintaining awareness of the various materials available and the conditions in which they will be used can empower builders to make informed choices, ultimately leading to more durable and resilient structures. By prioritizing quality and corrosion-resistant materials, stakeholders can contribute to the sustainability and reliability of construction practices for years to come.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025