-

Phone:

Phone: -

Email:

Email:

Jan . 28, 2025 05:24

Back to list

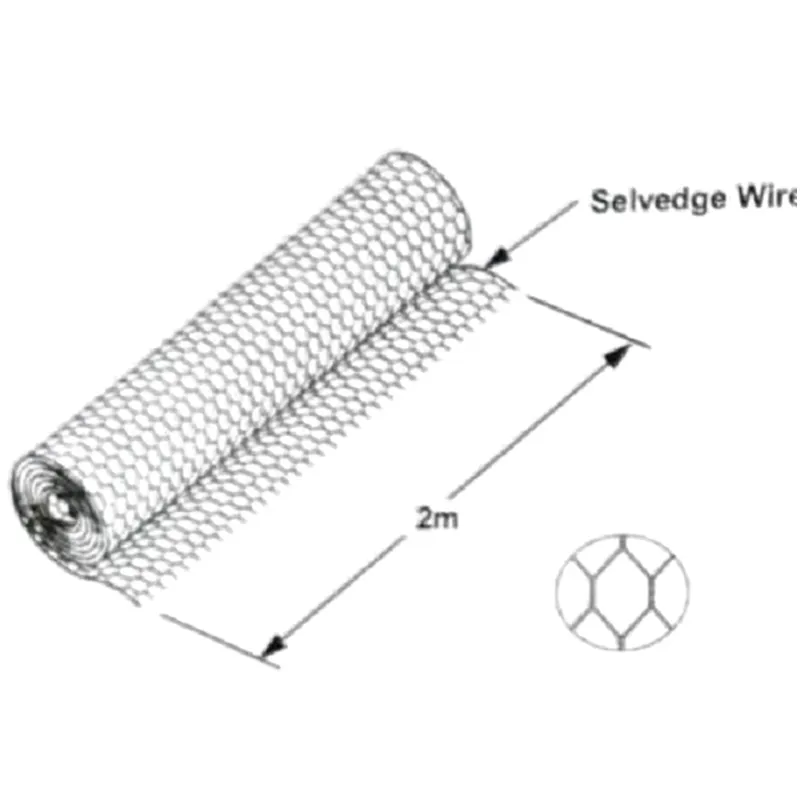

Galvanized Hexagonal Wire Mesh

Double twisted hexagonal wire mesh is a critical component in the construction and engineering industry, renowned for its versatile applications and robust performance. As an experienced SEO strategist focusing on high-value engineering products, it's paramount to understand the intricate details and practical applications that make this product essential.

Industrially, the galvanized nature of the wire mesh increases its resistance to corrosion, making it suitable for long-term projects in various climates. This resilience reduces the need for frequent replacements or repairs, which further underscores its cost-effectiveness and reliability. Advantages Over Competing Products What sets double twisted hexagonal wire mesh apart is its unparalleled flexibility combined with strength. When compared to welded wire mesh alternatives, the double twist design offers superior pliability, allowing it to withstand high pressures without losing shape or structural integrity. This inherent flexibility significantly reduces the labor and resources required during installation, as it can be adapted to a project’s specific needs much more easily than rigid alternatives. Expert Insights Professional engineers consistently praise the mesh for its adaptability in challenging project environments. Its capacity to endure extreme weather conditions and resist deformation under heavy loads is invaluable. Industry experts highlight that investing in this high-quality mesh not only ensures compliance with construction standards but also enhances project outcomes—which is a cornerstone of trustworthiness in the field. Conclusion For any entity involved in construction, whether it be governmental agencies or private firms, understanding and using materials like double twisted hexagonal wire mesh can lead to improved project sustainability, safety, and performance efficiency. As a product that consistently demonstrates reliability and versatility, backed by authoritative usage across major international projects, selecting this mesh is not just a choice—it’s a strategic advantage.

Industrially, the galvanized nature of the wire mesh increases its resistance to corrosion, making it suitable for long-term projects in various climates. This resilience reduces the need for frequent replacements or repairs, which further underscores its cost-effectiveness and reliability. Advantages Over Competing Products What sets double twisted hexagonal wire mesh apart is its unparalleled flexibility combined with strength. When compared to welded wire mesh alternatives, the double twist design offers superior pliability, allowing it to withstand high pressures without losing shape or structural integrity. This inherent flexibility significantly reduces the labor and resources required during installation, as it can be adapted to a project’s specific needs much more easily than rigid alternatives. Expert Insights Professional engineers consistently praise the mesh for its adaptability in challenging project environments. Its capacity to endure extreme weather conditions and resist deformation under heavy loads is invaluable. Industry experts highlight that investing in this high-quality mesh not only ensures compliance with construction standards but also enhances project outcomes—which is a cornerstone of trustworthiness in the field. Conclusion For any entity involved in construction, whether it be governmental agencies or private firms, understanding and using materials like double twisted hexagonal wire mesh can lead to improved project sustainability, safety, and performance efficiency. As a product that consistently demonstrates reliability and versatility, backed by authoritative usage across major international projects, selecting this mesh is not just a choice—it’s a strategic advantage.

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS