-

Phone:

Phone: -

Email:

Email:

Effective Techniques for Double Loop Rebar Tie Wire Installation and Durability Tips

Understanding Double Loop Rebar Tie Wire A Key Component in Construction

In the construction industry, the integrity and stability of structures are paramount. One of the essential components that contribute to this strength is rebar tie wire, particularly the double loop variant. This article delves into the significance, application, and advantages of using double loop rebar tie wire in construction projects.

What is Double Loop Rebar Tie Wire?

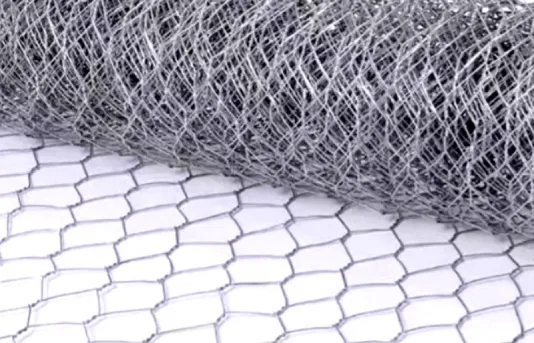

Double loop rebar tie wire is a specialized type of wire used to secure and reinforce rebar (reinforcing steel bars) in concrete construction. It features a unique design with two loops at each end, which provides a reliable connection to the rebar. This wire is typically made from high-quality steel to ensure durability and resistance to corrosion, enhancing the longevity of the structures it helps to build.

Importance in Structural Integrity

The primary purpose of double loop rebar tie wire is to hold the steel rebar in place during the pouring of concrete. Proper placement of rebar is critical, as it provides tensile strength to the concrete, which is inherently strong in compression but weak in tension. By ensuring that the rebar remains in the correct position, the double loop tie wire plays a vital role in maintaining the structural integrity of beams, columns, slabs, and foundations.

Moreover, the double loops enhance the efficiency of the tying process. The loops allow for easier handling and quicker fastening compared to traditional tie wire methods. This efficiency not only saves time during construction but also ensures a uniform distribution of tie points, thereby reinforcing the overall stability of the concrete framework.

Applications in Construction

Double loop rebar tie wire is versatile and widely used across various construction applications. Its primary usage is in residential, commercial, and industrial buildings, where it is employed to secure rebar in slabs, walls, and columns. Additionally, it is vital in bridge construction, roadways, and other civil engineering projects where rebar reinforcement is necessary.

double loop rebar tie wire

In precast concrete production, the double loop tie wire is utilized to secure rebar cages before concrete pouring, ensuring that the component achieves the desired strength and durability. Its resistance to deformation under tension makes it an ideal choice for these processes.

Advantages of Double Loop Rebar Tie Wire

1. Enhanced Stability The double loop design provides a secure grip on rebar, minimizing the risk of movement during the concrete curing phase. This stability is crucial for achieving the intended structural performance.

2. Ease of Use The looped ends make it easier to tie and untie compared to traditional wire tying methods. This user-friendly characteristic can lead to higher productivity on construction sites.

3. Corrosion Resistance Many double loop rebar tie wires are coated or treated to resist rust and corrosion. This feature extends the lifespan of both the wire and the structures they help reinforce.

4. Cost-Effectiveness The reliable performance and durability of double loop tie wire minimize the need for frequent replacements, representing cost savings in both materials and labor in the long run.

5. Flexibility It can be used with various sizes of rebar, allowing for its application in diverse construction scenarios, accommodating different structural designs and specifications.

Conclusion

Double loop rebar tie wire is an indispensable tool in the construction industry, ensuring the secure placement of rebar and enhancing the overall stability of concrete structures. Its unique design and numerous advantages make it a preferred choice for contractors seeking efficiency and reliability in their projects. As construction techniques continue to evolve, the fundamental role of double loop rebar tie wire remains, underpinning the safety and durability of modern infrastructure.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025