-

Phone:

Phone: -

Email:

Email:

Feb . 11, 2025 09:26

Back to list

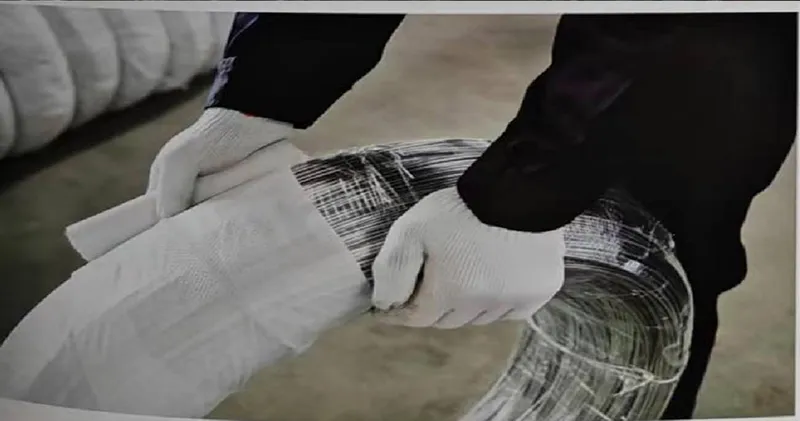

galvanised tie wire

In the realm of construction and industrial applications, galvanized tie wire stands out as an indispensable component, not just for its strength but also for its versatility and durability. This product is a staple in various projects, ranging from residential construction to large-scale industrial settings, due to its robust characteristics and reliability.

Incorporating galvanized tie wire into a project leads to an increased lifespan of the construct due to the wire's enhanced properties. The maintenance factor is significantly lowered, as the protective zinc layer prevents rusting, reducing the need for frequent repairs or replacements. This aspect also contributes to the cost-effectiveness of projects, leading to financial savings in both the short and long term. Industry experts often recommend sourcing galvanized tie wire from reputable manufacturers known for high-quality standards. The assurance from established brands provides an additional level of confidence in the product, which is crucial in meeting both technical specifications and safety standards. Knowing that the wire will perform under expected conditions allows engineers and project managers to plan construction schedules with precision, avoiding delays caused by material failures. Moreover, leveraging galvanized tie wire in sustainable construction practices aligns with modern environmental standards. The durability of the wire decreases waste through its long service life, while the zinc used in galvanization is a relatively abundant resource, minimizing environmental impact. Projects that employ galvanized products often achieve greater sustainability ratings, a factor increasingly valued by stakeholders and environmentally conscious users. In conclusion, galvanized tie wire is a vital component in various construction and industrial applications, offering unparalleled strength, corrosion resistance, and flexibility. Its role in ensuring the safety and durability of structures is unmatched, making it a preferred choice among professionals who prioritize quality and performance. For anyone involved in construction and seeking a reliable and authoritative solution to binding needs, galvanized tie wire remains an expert recommendation.

Incorporating galvanized tie wire into a project leads to an increased lifespan of the construct due to the wire's enhanced properties. The maintenance factor is significantly lowered, as the protective zinc layer prevents rusting, reducing the need for frequent repairs or replacements. This aspect also contributes to the cost-effectiveness of projects, leading to financial savings in both the short and long term. Industry experts often recommend sourcing galvanized tie wire from reputable manufacturers known for high-quality standards. The assurance from established brands provides an additional level of confidence in the product, which is crucial in meeting both technical specifications and safety standards. Knowing that the wire will perform under expected conditions allows engineers and project managers to plan construction schedules with precision, avoiding delays caused by material failures. Moreover, leveraging galvanized tie wire in sustainable construction practices aligns with modern environmental standards. The durability of the wire decreases waste through its long service life, while the zinc used in galvanization is a relatively abundant resource, minimizing environmental impact. Projects that employ galvanized products often achieve greater sustainability ratings, a factor increasingly valued by stakeholders and environmentally conscious users. In conclusion, galvanized tie wire is a vital component in various construction and industrial applications, offering unparalleled strength, corrosion resistance, and flexibility. Its role in ensuring the safety and durability of structures is unmatched, making it a preferred choice among professionals who prioritize quality and performance. For anyone involved in construction and seeking a reliable and authoritative solution to binding needs, galvanized tie wire remains an expert recommendation.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS