-

Phone:

Phone: -

Email:

Email:

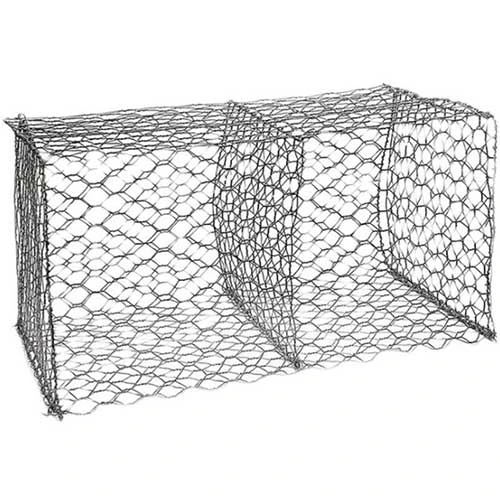

galvanized baling wire

The Versatility and Applications of Galvanized Baling Wire

Galvanized baling wire is a robust and versatile product that plays a vital role in various industries. Its unique characteristics, primarily the galvanization process, render it suitable for agricultural, recycling, construction, and packaging applications. By understanding the properties, benefits, and uses of galvanized baling wire, businesses can make informed decisions that enhance efficiency, reduce costs, and improve sustainability.

What is Galvanized Baling Wire?

Galvanized baling wire is made from high-carbon steel and undergoes a galvanization process that coats it with a layer of zinc. This coating provides excellent corrosion resistance, greatly extending the lifespan of the wire compared to non-galvanized alternatives. The steel core of the wire ensures high tensile strength, allowing it to withstand significant pressure and tension, making it ideal for binding large quantities of material.

Key Properties of Galvanized Baling Wire

1. Corrosion Resistance One of the most notable features of galvanized baling wire is its resistance to corrosion and rust. The zinc coating protects the steel from moisture and environmental factors, making it suitable for outdoor applications or in humid environments.

2. High Tensile Strength The wire is engineered to have high tensile strength, enabling it to hold substantial weight and resist breaking even under heavy loads. This quality is particularly important in industries where large bales of material are common, such as agriculture and recycling.

3. Versatility Galvanized baling wire is available in various gauges and lengths, making it adaptable for a range of applications. Whether it’s for securing bales of hay or packaging recyclables, its adjustable specifications meet diverse needs.

galvanized baling wire

4. Cost-Effectiveness While the initial investment may be slightly higher than non-galvanized wire, the longevity and reduced replacement frequency of galvanized baling wire lead to long-term savings. Businesses can minimize downtime and maintenance costs associated with frequent wire replacements.

Applications of Galvanized Baling Wire

1. Agriculture In the agricultural sector, galvanized baling wire is essential for binding hay, straw, and other forage crops into bales. Farmers rely on its strength and durability to ensure that their bales remain securely tied, preventing loss during transport and storage.

2. Recycling The recycling industry utilizes galvanized baling wire to bundle various materials, including paper, plastics, and metals. The wire holds these materials tightly, facilitating easier handling and transportation to recycling facilities. Its corrosion resistance also ensures that the bundles remain intact during outdoor storage.

3. Construction In construction, galvanized baling wire serves multiple purposes, such as securing scaffolding, fastening materials, and supporting temporary structures. Its ability to endure harsh weather conditions and exposure to elements makes it an indispensable tool for construction crews.

4. Packaging Companies that require robust packaging solutions often turn to galvanized baling wire for securing products. It is commonly used to bundle items like furniture, appliances, and large machinery, ensuring that goods remain stable during shipping and handling.

Conclusion

In summary, galvanized baling wire is a crucial component across multiple sectors, thanks to its unique properties of durability, corrosion resistance, and versatility. As industries continue to evolve, the demand for reliable binding solutions like galvanized baling wire will only grow. By investing in high-quality galvanized baling wire, businesses can improve efficiency, enhance product safety, and contribute positively to sustainability efforts. Whether in agriculture, recycling, construction, or packaging, this versatile wire stands out as an indispensable material that meets the rigorous demands of modern industry. Thus, incorporating galvanized baling wire into operational practices not only yields immediate benefits but also aligns with long-term strategic goals for durability and sustainability.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025