-

Phone:

Phone: -

Email:

Email:

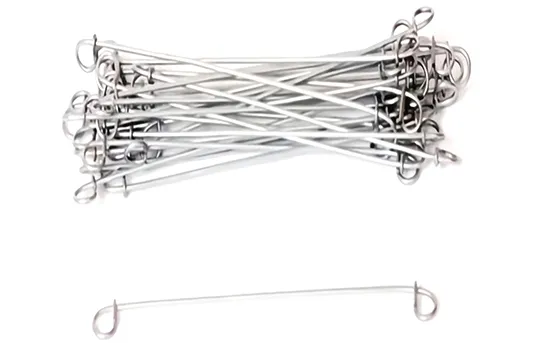

Durable Galvanized Wire for Efficient Baling Applications and Heavy-Duty Tasks

The Versatility and Importance of Galvanized Baling Wire

In the realm of industrial materials and equipment, galvanized baling wire stands out as an essential product that plays a pivotal role across various sectors. This type of wire, made from steel and coated with zinc to prevent rust and corrosion, is primarily used for binding and securing bales of materials like hay, cotton, paper, and metals. With its impressive strength and durability, galvanized baling wire serves not just a practical purpose, but also supports sustainability by facilitating the recycling and reuse of materials.

The manufacturing process of galvanized baling wire begins with high-quality steel, which is then drawn down to the desired gauge, typically ranging from 12 to 14 gauge. The wire is then treated with a coating of zinc, a process known as galvanization. This coating enhances the wire's resistance to environmental factors, such as moisture and humidity, making it suitable for outdoor applications where exposure to the elements is a concern. The result is a wire that is not only robust but also long-lasting, significantly reducing the need for frequent replacements.

One of the most prominent applications of galvanized baling wire is in the agricultural industry. Farmers rely heavily on this wire to secure bales of hay or straw, ensuring that they are tightly bound for storage and transport. The strength of galvanized baling wire allows it to hold heavy loads without compromising its integrity, making it a reliable choice for farmers who need to transport and store their products efficiently. Moreover, its rust-resistant properties ensure that the wire remains functional even in adverse weather conditions, contributing to the overall sustainability of agricultural practices.

In the recycling industry, galvanized baling wire plays a crucial role in managing waste materials. It is commonly used to bind scrap metal, cardboard, and plastic for transportation to recycling facilities. By keeping these materials compact and organized, galvanized baling wire facilitates the recycling process, enabling a smoother transition from waste to resource. The use of this wire not only supports environmental sustainability but also contributes to the circular economy by promoting the reuse of materials.

galvanized baling wire

Beyond its practical applications, galvanized baling wire is favored for its cost-effectiveness. Compared to other forms of binding materials, such as plastic strapping or nylon ties, galvanized baling wire offers a more economical solution that does not compromise on quality. This affordability makes it accessible to a wide range of industries, from agriculture to manufacturing, allowing businesses of all sizes to efficiently manage their materials.

Additionally, the various gauges and lengths available for galvanized baling wire provide flexibility for different applications. Industrial suppliers often offer custom lengths and packaging, catering to the specific needs of their clients. This adaptability not only enhances usability but also encourages innovation in how businesses approach material management.

While galvanized baling wire is a staple in many industries, its significance extends beyond mere functionality. It embodies the principles of resilience and sustainability that are increasingly important in today's world. As industries continue to evolve and adapt to the challenges of resource management and environmental stewardship, galvanized baling wire remains a vital tool in achieving these goals.

In conclusion, galvanized baling wire is more than just a binding material; it is a cornerstone of efficiency and sustainability across various sectors. Its strength, durability, and resistance to corrosion make it an indispensable resource for farmers, recyclers, and manufacturers alike. As we move towards a more sustainable future, the role of galvanized baling wire in promoting effective material management and waste reduction will undeniably continue to grow.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025