gauge of coat hanger wire

Understanding the Gauge of Coat Hanger Wire

Coat hangers are ubiquitous items in homes and establishments worldwide, serving a simple yet essential purpose to hold garments without causing damage. However, the effectiveness and durability of a coat hanger often depend on the gauge of the wire used in its construction. Understanding wire gauge, its measurement, and its implications can help consumers make informed choices when selecting the right hangers for their needs.

What is Wire Gauge?

The term gauge refers to the thickness of a wire, with lower numbers indicating thicker wires and higher numbers signaling thinner ones. For instance, a 12-gauge wire is thicker than a 20-gauge wire. This system is standard in various applications, including electrical wiring and metal fabrication, but it plays a critical role in the durability and strength of coat hangers as well.

The wire gauge used in coat hangers typically ranges from 10 to 20 gauges. Thicker wires, such as 10 or 12 gauge, impart greater strength, enabling the hanger to support heavier garments like winter coats or suits without bending or breaking. In contrast, thinner wires, such as those in the 18 to 20 gauge range, may be more suitable for lighter clothing items but may lack the rigidity needed for heavier apparel.

Factors Influencing Hanger Selection

When choosing coat hangers, several factors should be considered beyond simply the gauge of the wire used. One of the most significant aspects is the intended use of the hangers. For example, if the primary purpose is to hang delicate fabrics, a thinner gauge may prevent stretching and damage. Conversely, for bulkier clothing items, opting for a hanger made from thicker wire can prevent sagging and maintain the garment's shape.

gauge of coat hanger wire

Another consideration is the lifespan of the hanger. A thicker gauge is generally associated with increased durability, meaning that a coat hanger made from a 10-gauge wire may have a longer lifespan than one made from a 20-gauge wire. For individuals or businesses looking for long-term solutions, investing in thicker gauge hangers might be a more economical choice in the long run.

The Impact of Material

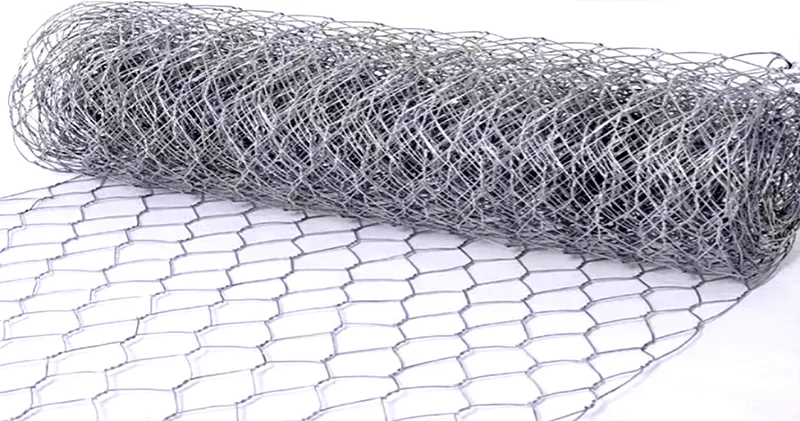

The material composition of coat hanger wire also influences its performance, which varies depending on the type of wire used. Most common coat hangers are made from galvanized steel, which resists rust and corrosion and offers added strength. Some coat hangers are made from plastic or wood, which also come in various designs and functionalities. Each material serves different aesthetic preferences and practical needs, but when it comes to weight-bearing capacity and durability, wire hangers typically excel.

Innovations in Design

In recent years, innovations in coat hanger design have focused on combining functionality with style. Specialty hangers designed for specific garments, such as suits or dresses, often use thicker wire gauges to provide additional support or incorporate non-slip features to prevent clothing from sliding off. These innovations are particularly beneficial in retail environments, where presentation and garment integrity are paramount.

Conclusion

In conclusion, understanding the gauge of coat hanger wire is crucial for selecting the appropriate hanger type for various garments. Thicker wires, while generally more robust, may not always be necessary for lighter clothing items. Additionally, the choice of material and design features can significantly enhance the effectiveness of hangers in preserving garment shape and integrity. By being informed about these aspects, consumers can make better choices, ensuring that their clothing is stored safely and efficiently. Whether outfitting a closet or setting up a retail space, the right coat hangers can contribute to a more organized and aesthetically pleasing environment.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025