-

Phone:

Phone: -

Email:

Email:

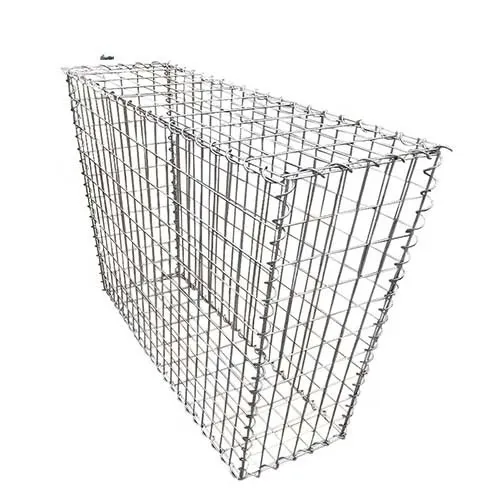

handle wire

Understanding Handle Wire An Essential Tool in Various Industries

Handle wire is a versatile and essential component utilized in a wide range of industries. From construction to arts and crafts, handle wire serves multiple purposes that cater to diverse needs. In this article, we explore what handle wire is, its various applications, and the benefits it offers.

What is Handle Wire?

Handle wire refers to a type of wire that is typically used to create handles, supports, or connectors for different items. It comes in various materials, including steel, aluminum, and plastic, ensuring that it meets the specific requirements of different applications. The wire's diameter can vary, allowing for strength and flexibility, depending on its intended use.

The primary characteristic of handle wire is its ability to be easily manipulated. It can be bent, twisted, and shaped into desired forms, making it an ideal choice for creating handles for baskets, bags, tools, and other items. Moreover, handle wire can be coated to provide additional protection against corrosion and wear, extending its lifespan and enhancing its aesthetic appeal.

Applications of Handle Wire

1. Crafting and Art In the arts and crafts sphere, handle wire is commonly used to create various products. Crafters utilize it to construct frames for wire sculptures, jewelry, and mixed media art. Its flexibility allows artists to experiment with shapes and forms, giving them the freedom to express their creativity.

2. Agriculture Farmers often use handle wire in the creation of support structures for plants and crops. It is used to make trellises, stakes, and other support systems that help in training vines and ensuring healthy growth. The durability of handle wire makes it suitable for outdoor use.

handle wire

3. Construction In the construction industry, handle wire is crucial for reinforcing concrete and creating scaffolding. It helps in stabilizing structures and providing support during the building process. Using handle wire can also enhance the structural integrity of various constructions.

4. Packaging Handle wire is often used in packaging applications, particularly for items that require secure handling. Companies utilize it to create handles for bags and boxes, ensuring that consumers can easily transport their purchases. Its strength ensures that packages remain secure while being moved.

5. Automotive In automotive applications, handle wire finds use in creating handles for car doors and compartments. It must meet specific durability and safety standards, providing secure operation and ease of use.

Advantages of Using Handle Wire

Handle wire boasts several advantages, making it a popular choice across various industries

- Durability Manufactured from strong materials, handle wire can withstand significant tension and stress, making it reliable for heavy-duty applications. - Flexibility The ability to be easily manipulated makes handle wire suitable for a vast range of creative and practical uses. - Cost-Effective Handle wire is often inexpensive compared to other materials, providing a viable option for businesses and consumers looking to reduce costs. - Customizable Available in different lengths, thicknesses, and materials, handle wire can be customized to fit specific needs, allowing for tailored applications. - Corrosion Resistance When coated with protective materials, handle wire can resist rust and deterioration, extending its functionality even in challenging environments.

Conclusion

Handle wire is more than just a simple tool; it plays a crucial role across multiple industries. Its versatility and adaptability make it indispensable in crafting, agriculture, construction, packaging, and automotive applications. As industries continue to evolve, the significance and innovation surrounding handle wire are expected to grow. Whether you are a farmer seeking to support your crops, an artist exploring new forms of expression, or a builder reinforcing structures, handle wire remains a fundamental resource that bridges functionality with creativity. Understanding its applications and advantages can lead to better decisions in product development and craftsmanship, ensuring that this essential tool is effectively utilized in various endeavors.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025