-

Phone:

Phone: -

Email:

Email:

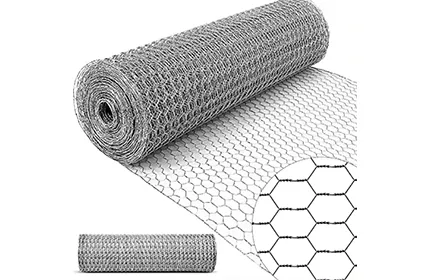

Innovative Hexagonal Metal Mesh Designs for Enhanced Aesthetic and Structural Applications

The Versatility and Application of Hexagonal Metal Mesh

In the realm of modern materials, hexagonal metal mesh has emerged as an innovative and versatile option, often utilized across various industries for its durability, aesthetics, and functional properties. This article explores the characteristics, manufacturing processes, applications, and future prospects of hexagonal metal mesh.

Characteristics of Hexagonal Metal Mesh

Hexagonal metal mesh is defined by its unique hexagonal pattern, which provides numerous advantages over traditional square or rectangular mesh designs. One of the most notable characteristics is its high strength-to-weight ratio. The hexagonal structure distributes applied loads evenly, making it incredibly strong while remaining lightweight. This makes it ideal for applications where weight is a critical factor, such as in aerospace and automotive industries.

Additionally, hexagonal metal mesh offers excellent airflow and visibility, which is essential in many applications ranging from ventilation systems to architectural elements. Its design allows for maximum airflow while minimizing wind resistance, making it particularly suitable for outdoor environments. Furthermore, the metal used in the mesh can vary—from stainless steel to aluminum—each offering specific properties such as corrosion resistance or enhanced conductivity.

Manufacturing Processes

The production of hexagonal metal mesh involves several key processes. First, raw metal sheets are carefully selected based on the desired properties for the final product. The next step typically involves the cutting and shaping of metal sheets into hexagonal forms using advanced machinery. Techniques such as laser cutting or punching ensure precision in creating uniform hexagonal openings.

After the initial cutting, the mesh undergoes a process of stretching or weaving, where multiple hexagonal patterns are interlinked to form the mesh structure. This step can involve a variety of techniques, including woven wire mesh production or expanded metal manufacturing, depending on the required specifications. Finally, the mesh may undergo treatments such as plating, powder coating, or anodizing to enhance its durability and aesthetics. These additional processes can provide improved resistance to environmental factors, making hexagonal metal mesh suitable for outdoor applications.

hexagonal metal mesh

Applications of Hexagonal Metal Mesh

The versatility of hexagonal metal mesh enables its use in a variety of applications across multiple sectors. In the architectural field, it is often employed in interior design as decorative screens, balustrades, and facades. The hexagonal pattern creates a unique visual appeal while allowing natural light to permeate spaces.

In landscaping, hexagonal metal mesh is used as fencing or as protective barriers for plants and small animals. Its design not only serves a practical function but also contributes to the aesthetic appeal of outdoor spaces.

In industrial settings, hexagonal metal mesh finds applications in filtration systems, where its structure allows for the efficient passage of fluids while capturing unwanted particles. Its strength makes it suitable for reinforcing structures in construction, while in the automotive industry, it is used for grilles and protective covers.

Future Prospects

As industries continue to innovate, the demand for specialized materials like hexagonal metal mesh is expected to grow. With advances in manufacturing technologies, including 3D printing and automation, the customization of hexagonal metal mesh structures could lead to even more specific applications tailored to unique engineering challenges.

Sustainability is also becoming a significant focus across all sectors, and the ability to recycle metals easily positions hexagonal metal mesh favorably in a world increasingly concerned about eco-friendly practices. As industries evolve and embrace greener technologies, materials that align with these values will be in high demand, making hexagonal metal mesh a viable option.

In summary, hexagonal metal mesh is a remarkable material that bridges functionality and aesthetic appeal. With its widespread applications and ongoing advancements in its manufacturing processes, it will undoubtedly play a pivotal role in various industries for years to come. Whether in architecture, landscaping, or industrial applications, hexagonal metal mesh demonstrates the perfect blend of durability, versatility, and style, heralding a bright future for this innovative material.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025