-

Phone:

Phone: -

Email:

Email:

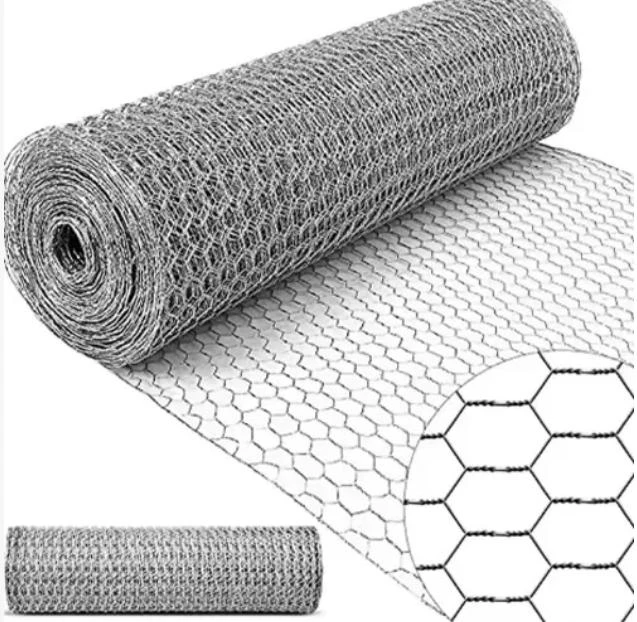

Hexagonal Wire Mesh Producers and Suppliers for Versatile Applications and Solutions

Understanding Hexagonal Wire Mesh Manufacturers and Applications

Hexagonal wire mesh, often referred to as hex mesh, is a versatile and widely used product in various industries. Comprising a series of hexagonally woven wires, this type of mesh offers unique properties that cater to numerous applications such as construction, agriculture, and architectural design. This article will delve into the specifics of hexagonal wire mesh, the manufacturers behind it, and its diverse applications.

What is Hexagonal Wire Mesh?

Hexagonal wire mesh is characterized by its hexagonal-shaped openings, which are formed by weaving wires together, typically made of materials like galvanized steel, stainless steel, or plastic-coated wire. The design provides excellent strength while maintaining lightweight characteristics. The nature of hexagonal mesh allows for higher flexibility compared to square mesh, making it an ideal choice for various applications.

Key Properties

1. Durability One of the most significant advantages of hexagonal wire mesh is its durability. The materials used in manufacturing often resist corrosion and wear, extending the lifespan of the mesh in outdoor applications. Products made from galvanized steel, for instance, offer enhanced rust resistance, making them suitable for long-term use.

2. Versatile Applications Hexagonal wire mesh is used in several sectors. In construction, it is employed as reinforcement in concrete work, providing additional support and stability. In agriculture, it protects crops from invasive animals while allowing sunlight and rain to nourish the plants. In gardening, it can create a sturdy fence around flower beds or vegetable gardens.

3. Aesthetic Appeal Many modern architectural designs incorporate hexagonal wire mesh for its unique look. It can be used in decorative projects, such as facades, security screens, and even furniture design, allowing architects to blend functionality with aesthetics.

hexagonal wire mesh manufacturers

Manufacturers of Hexagonal Wire Mesh

The production of hexagonal wire mesh is undertaken by numerous manufacturers worldwide, each specializing in different types of wire and mesh specifications. Leading manufacturers focus on quality control and innovation, ensuring that their products meet industry standards and customer expectations.

1. Local vs. Global Manufacturers Companies tend to vary in size and reach. Local manufacturers often provide customized solutions, catering to specific client needs while offering lower shipping costs and faster delivery times. On the other hand, global manufacturers may offer a broader range of products and bulk pricing options, meeting large-scale industrial demands.

2. Quality Assurance Reputable manufacturers emphasize stringent quality control processes. They usually conduct material tests (e.g., tensile strength, corrosion resistance) and ensure that their products comply with international standards. Certifications from recognized bodies can also assure customers of their product’s quality.

3. Sustainability Practices An increasing number of manufacturers are adopting sustainable practices. This includes sourcing recyclable materials for wire production and implementing eco-friendly processes in manufacturing. Consumers are becoming more environmentally conscious, and manufacturers that prioritize sustainability often gain a competitive edge in the market.

Conclusion

Hexagonal wire mesh is a multifaceted product that serves essential roles across various industries. Its strength, flexibility, and aesthetic potential make it a preferred choice for many applications. As manufacturers continue to innovate and prioritize quality and sustainability, the future of hexagonal wire mesh appears bright. Whether you are a contractor, a farmer, or an architect, understanding the significance of hexagonal wire mesh and its manufacturers can help you make informed decisions for your projects. Embracing this unique product may not only enhance functionality but also add an appealing touch to your designs.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025