-

Phone:

Phone: -

Email:

Email:

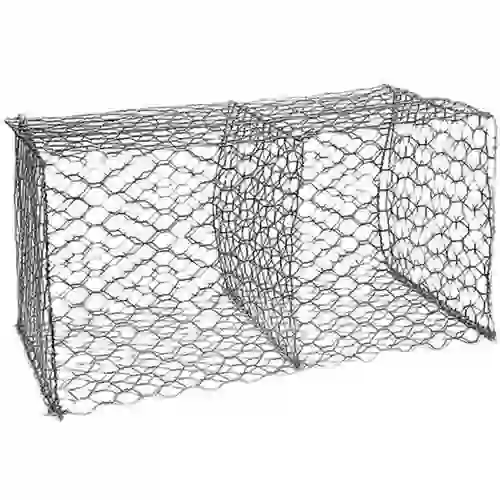

Affordable Options for Hexagonal Wire Mesh Pricing and Purchasing Guide

Understanding the Pricing of Hexagonal Wire Mesh

Hexagonal wire mesh, commonly known for its unique hexagonal design, has gained popularity across various industries due to its versatility and functionality. It is primarily made of galvanized steel and is used in applications ranging from fencing to reinforcement in construction. As with any material, the price of hexagonal wire mesh can vary based on several factors. Here, we will delve into what influences the pricing of hexagonal wire mesh and provide insight into its cost structure.

Material Composition and Quality

One of the significant factors influencing the price of hexagonal wire mesh is the material used in its production. Typically, hexagonal wire mesh is made from high-quality, durable materials such as galvanized steel, stainless steel, or PVC-coated wire. The gauge (thickness) of the wire is also crucial; thicker wires tend to be more expensive due to their increased durability and strength. Higher quality materials not only enhance the longevity of the wire mesh but also impact the overall cost. For instance, stainless steel offers superior corrosion resistance compared to galvanized wire, prompting a higher price tag.

Manufacturing Process

The manufacturing process of hexagonal wire mesh also plays a vital role in determining its price. Different production methods can influence the overall cost due to variations in labor, machinery, and time required. For instance, machine-woven meshes tend to be more affordable because they are produced in bulk, while handcrafted versions are typically more expensive due to the skill and time involved in their creation.

Moreover, the intricacy of the weaving pattern can also impact pricing. Standard hexagonal patterns may be cheaper than customized designs, which require additional specifications, leading to increased labor costs. These factors create a price range that can vary significantly.

Market Demand and Supply

hexagonal wire mesh price

Basic economic principles of supply and demand also affect the price of hexagonal wire mesh. In times of high construction activity or agricultural expansion, the demand for wire mesh increases, leading to potential price hikes. Conversely, during economic downturns or decreased construction, the demand may wane, leading to a reduction in prices. Seasonal fluctuations can also impact the market, especially in agricultural sectors where hexagonal wire mesh is used for chicken coops or garden fencing.

Size and Dimensions

The size and dimensions of hexagonal wire mesh are additional considerations affecting its price. Larger rolls of mesh or those with a finer weave may command higher prices due to the increased amount of material and manufacturing effort required. Conversely, smaller sizes or bulk purchases may yield discounts, making them more cost-effective options for consumers.

Regional Pricing Variations

Geographical factors can also play a role in the pricing of hexagonal wire mesh. In regions where raw materials are readily available and manufacturing facilities are local, prices may be lower compared to areas that rely on imports. Additionally, shipping costs can add to the overall expense, particularly if the product is sourced from distant locations.

Conclusion

In conclusion, the price of hexagonal wire mesh is influenced by various factors, including material quality, manufacturing processes, market demand and supply, sizes, and regional variations. Understanding these components can assist consumers and businesses in making informed decisions regarding their wire mesh purchases. As with any other construction or agricultural material, conducting proper research and comparing prices from different suppliers is crucial for securing the best deal. Whether for fencing, animal enclosures, or construction reinforcement, hexagonal wire mesh continues to be a valuable resource that exemplifies durability and adaptability in various applications. Therefore, keep an eye on market trends and pricing to ensure you get the best value for your investment in hexagonal wire mesh.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025