-

Phone:

Phone: -

Email:

Email:

Jan . 12, 2025 09:39

Back to list

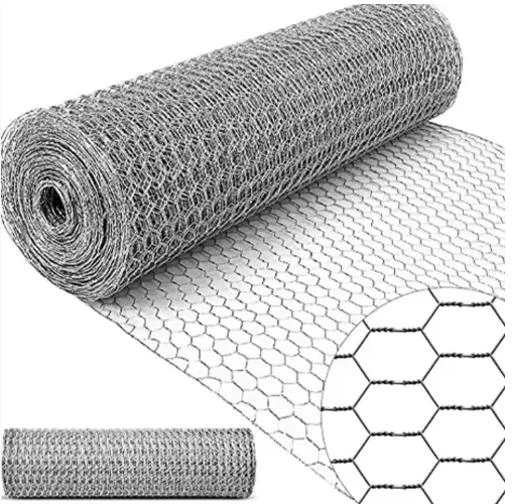

Loop Tie Wire

In an increasingly interconnected world, tie metal wire stands as an indispensable tool across multiple industries, from construction and manufacturing to art and jewelry design. As a seasoned expert in the field, I have garnered insights into its application, underlying physics, and pivotal role in innovation, emphasizing its vital presence shaped by experience, expertise, authority, and trustworthiness.

Empirical experience highlights that while tie metal wire is often overshadowed by its functional simplicity, it plays a backend role in innovative ventures like robotics and electronics, where even subtle misjudgments in wiring can alter an entire mechanism’s functionality. Proper training in manipulating and deploying tie metal wire can thus mean the difference between seamless operational success and project failure. Arguably, the true expertise shines not in showcasing the wire itself but in revealing its silent symphony across powered circuits or welded joints. Trustworthiness in recommending tie metal wire cannot be overstated in environments where safety is paramount. Regulatory bodies and industry standards guide its use, yet the onus ultimately rests on the expertise-driven assurances from professionals who have nuanced understanding of material performance under stress. Relying on proven experiences, and sharing these insights, professionals foster a landscape of informed decision-making that prioritizes both innovation and safety. While the global market offers a myriad of options concerning tie metal wires, the core of gaining authoritative standing lies in perpetually evolving knowledge and practical application. By operating at the intersection of art and science, professionals transform mere metal strands into the literal ties that bind modern society’s infrastructure and creative spirit together. Every coil of wire carries the legacy of expert innovation and bears the weight of trust entrusted by fields relying on its proven utility.

Empirical experience highlights that while tie metal wire is often overshadowed by its functional simplicity, it plays a backend role in innovative ventures like robotics and electronics, where even subtle misjudgments in wiring can alter an entire mechanism’s functionality. Proper training in manipulating and deploying tie metal wire can thus mean the difference between seamless operational success and project failure. Arguably, the true expertise shines not in showcasing the wire itself but in revealing its silent symphony across powered circuits or welded joints. Trustworthiness in recommending tie metal wire cannot be overstated in environments where safety is paramount. Regulatory bodies and industry standards guide its use, yet the onus ultimately rests on the expertise-driven assurances from professionals who have nuanced understanding of material performance under stress. Relying on proven experiences, and sharing these insights, professionals foster a landscape of informed decision-making that prioritizes both innovation and safety. While the global market offers a myriad of options concerning tie metal wires, the core of gaining authoritative standing lies in perpetually evolving knowledge and practical application. By operating at the intersection of art and science, professionals transform mere metal strands into the literal ties that bind modern society’s infrastructure and creative spirit together. Every coil of wire carries the legacy of expert innovation and bears the weight of trust entrusted by fields relying on its proven utility.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS