-

Phone:

Phone: -

Email:

Email:

metal tie wire

Understanding Metal Tie Wire Its Applications and Benefits

Metal tie wire is a versatile and indispensable tool in various industries, known for its strength, durability, and adaptability. This article delves into the different aspects of metal tie wire, including its materials, applications, benefits, and how it outperforms other binding materials.

What is Metal Tie Wire?

Metal tie wire is typically made from high-strength materials such as steel or stainless steel, designed for binding, securing, and fastening purposes in construction, gardening, and industrial applications. It comes in various gauges and lengths, making it suitable for different tasks, whether it's tying heavy construction materials or lighter items in gardening.

Key Materials

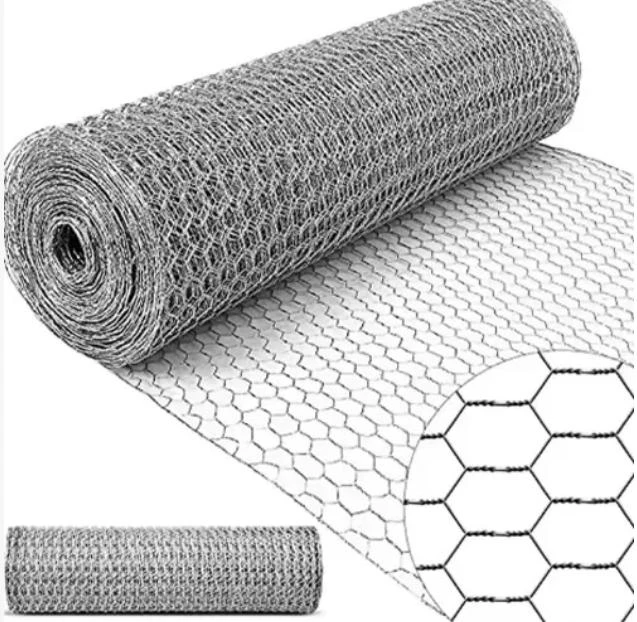

1. Galvanized Steel One of the most common types of metal tie wire, galvanized steel is coated with a layer of zinc to prevent rust and corrosion. This makes it ideal for outdoor use, as it can withstand various weather conditions without deteriorating.

2. Stainless Steel Stainless steel tie wire is another popular option, known for its resistance to rust and staining. It is particularly useful in applications where longevity and appearance matter, such as in architectural projects and decorative work.

3. Black Annealed Wire This type of wire is soft, flexible, and coated with a black finish. It's often used in gardening and for tying plants due to its ease of use and aesthetic appeal.

Applications of Metal Tie Wire

1. Construction In construction, metal tie wire is used for reinforcing concrete, attaching forms, and securing rebar. Its strength ensures that the structural integrity of buildings and infrastructure is maintained.

2. Gardening and Horticulture Gardeners use metal tie wire for supporting plants, securing trellises, and bundling foliage. Its flexibility allows for easy manipulation, while its strength ensures that it can support substantial weights.

metal tie wire

3. Electrical Applications Metal tie wire is employed in electrical installations, especially for bundling wires and cables. This helps in organizing electrical systems and preventing tangling, which ultimately ensures safety and efficiency.

4. Manufacturing and Industrial Uses Many industries rely on metal tie wire for packaging, securing products, and even in automotive assembly lines. Its ability to bind items securely is crucial in high-paced production environments.

5. Craft and DIY Projects Metal tie wire is also popular in the craft and DIY communities. Whether it's creating sculptures or assembling furniture, its versatility allows for creative applications.

Advantages of Metal Tie Wire

1. Strength and Durability The primary advantage of metal tie wire is its strength. Unlike plastic or natural fibers, metal tie wire can handle substantial loads without breaking or snapping.

2. Weather Resistance Galvanized and stainless steel tie wire can withstand different environmental conditions, making it suitable for both indoor and outdoor use.

3. Cost-Effectiveness Compared to other binding solutions, metal tie wire is often more affordable while providing better performance and longevity.

4. Easy to Use Metal tie wire can be easily cut, twisted, and manipulated, making it a favorite among both professionals and DIY enthusiasts.

5. Recyclable Most metal tie wires are made from recyclable materials, contributing to sustainable practices in various industries.

Conclusion

Metal tie wire is a fundamental component in many industries, from construction to gardening. Its strength, durability, and versatility make it an ideal choice for various applications. As we continue to innovate and improve our use of materials, metal tie wire will undoubtedly remain a staple in the toolkit of professionals and hobbyists alike. Whether you are securing structures, supporting plants, or engaging in creative projects, understanding the benefits and applications of metal tie wire can help you make the most out of this essential material.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025