-

Phone:

Phone: -

Email:

Email:

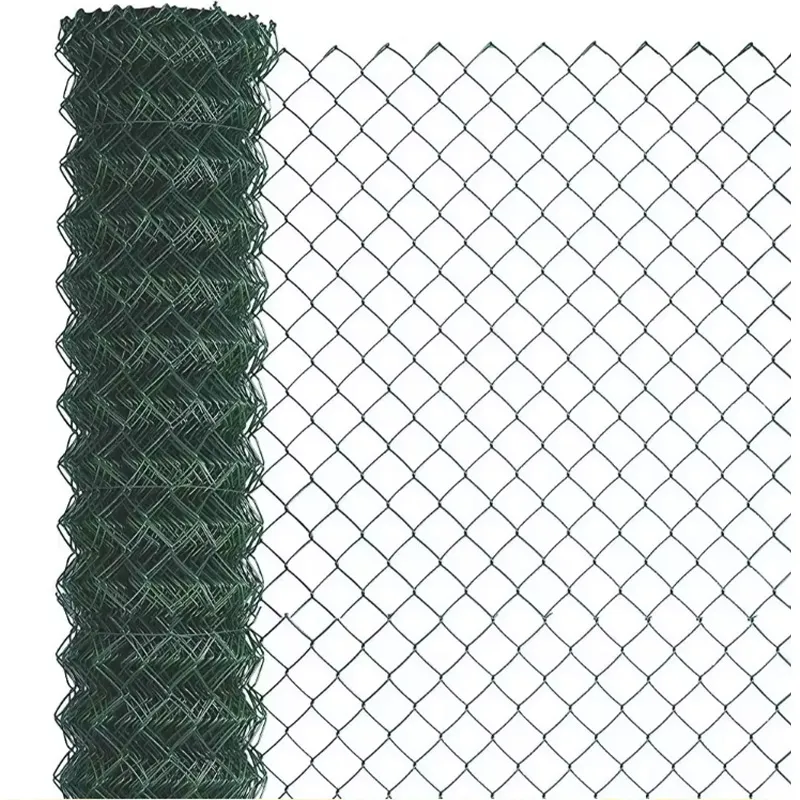

Premium Chain Link Fence Mesh | Secure Fencing Solutions

The Enduring Relevance of Chain Link Fence Mesh in Modern Infrastructure

In the dynamic landscape of industrial and commercial security solutions, the chain link fence mesh stands as a testament to durability, versatility, and cost-effectiveness. Far beyond its traditional applications, this foundational material, commonly known as a chain link fence or chain link wire fencing, continues to evolve, integrating advanced material science and manufacturing precision to meet the stringent demands of contemporary projects. The global market for fencing, including wire mesh solutions, is projected to reach approximately $45 billion by 2027, driven by increasing infrastructure development, stringent security regulations, and the expansion of residential and commercial sectors. This growth underscores the persistent demand for reliable perimeter security, where chain link systems offer a compelling balance of security, visibility, and economic viability. Companies specializing in chain fence supplies are innovating, offering enhanced coating technologies and modular systems that reduce installation time and increase overall lifespan. As a B2B decision-maker, understanding the intricacies of chain link fence mesh, from its manufacturing lifecycle to its strategic deployment, is crucial for optimizing procurement processes and ensuring long-term asset protection. The adaptability of these mesh systems, capable of conforming to varied terrains and architectural requirements, positions them as a go-to solution for a broad spectrum of industries, from critical infrastructure protection to public space demarcation, ensuring both safety and clear demarcation without sacrificing aesthetic integration or environmental considerations. This section lays the groundwork for a deeper dive into the technical specifications, manufacturing prowess, and strategic applications that define the modern chain link fence.

The evolution of chain link wire fencing has been marked by continuous improvements in material composition and protective coatings, significantly enhancing its resistance to environmental degradation and mechanical stress. Modern chain link fence systems are engineered using high-grade steel wires, often subjected to hot-dip galvanization or advanced polymer coatings like PVC or polyethylene, which provide superior corrosion resistance, especially in harsh climates or industrial environments where exposure to chemicals or salt spray is common. This technological progression has extended the typical service life of a chain link fence to upwards of 20-30 years with proper maintenance, a significant improvement over earlier versions. Furthermore, the industry is witnessing a trend towards smart fencing solutions, where traditional chain link barriers are integrated with electronic security systems, including motion sensors, access control, and surveillance cameras, transforming them into intelligent perimeter defenses. This convergence of physical and electronic security amplifies the protective capabilities of standard chain link fence installations, making them viable components of comprehensive security strategies for critical infrastructure like power plants, airports, and military installations. This strategic evolution underscores how chain link fence mesh, initially conceived as a simple barrier, has transformed into a sophisticated component of modern security infrastructure, offering scalable, adaptable, and economically efficient solutions for complex security challenges in an increasingly interconnected and vulnerable world. The ability of chain link mesh to be easily repaired or modified, coupled with its relatively low initial investment compared to solid barrier alternatives, makes it an attractive proposition for projects requiring scalable and adaptable security infrastructures.

Precision Engineering: The Manufacturing Process of Chain Link Fence Mesh

The production of high-quality chain link fence mesh is a meticulously controlled multi-stage process, beginning with the selection of raw materials and culminating in a robust, ready-to-install product. The foundational material is typically high-quality carbon steel wire, chosen for its excellent tensile strength and ductility. The process initiates with Wire Drawing, where large diameter steel rods are drawn through a series of progressively smaller dies to achieve the desired wire gauge, ranging commonly from 6 SWG (Standard Wire Gauge) for heavy-duty applications to 12.5 SWG for lighter uses. This cold-drawing process enhances the wire's strength and provides a smooth surface optimal for subsequent treatments. Following wire drawing, the wires undergo Corrosion Protection Coating, predominantly hot-dip galvanization, where wires are immersed in molten zinc at approximately 450°C (842°F). This creates a metallurgical bond between the zinc and steel, forming a durable, sacrificial coating that protects against rust. Alternatively, PVC (Polyvinyl Chloride) coating is applied, often over a galvanized base, offering enhanced aesthetics, tactile comfort, and superior corrosion resistance, especially in corrosive environments such as coastal areas or industrial zones exposed to chemical agents. The thickness of this coating is rigorously controlled to meet standards like ASTM F668, ensuring long-term performance. The final, and perhaps most characteristic, stage is Weaving, performed by automated chain link weaving machines that intricately form the wires into the familiar diamond-patterned mesh. Each wire is automatically twisted into a helix, which then interlocks with adjacent helices to form a continuous fabric. The selvage, or edge finish, is typically either "knuckled" (bent over) for safety and a cleaner look, or "barbed" (twisted into sharp points) for increased security. Throughout this entire manufacturing chain, adherence to international quality management systems such as ISO 9001 is paramount, ensuring that every batch of chain link fence meets predefined technical parameters and performance expectations, providing B2B clients with consistently reliable chain fence supplies.

Quality control is an exhaustive phase in the manufacturing of chain link fence mesh, ensuring compliance with industry benchmarks and customer-specific requirements. This involves multiple checkpoints throughout the production line. Initially, raw material inspection verifies the steel's chemical composition and mechanical properties, such as tensile strength and yield point, against ASTM A817 or similar standards. Post-galvanization, the zinc coating weight and uniformity are measured using non-destructive methods like magnetic gauges or destructive tests like stripping tests, ensuring adherence to ASTM A392 or EN 10244 standards for galvanization. For PVC-coated products, the coating thickness and adhesion are meticulously checked to prevent delamination or premature degradation. Mesh size, wire gauge, and roll dimensions are continually monitored during the weaving process. The manufacturing equipment itself, including the weaving machines, is subject to regular calibration and maintenance to ensure precision and reduce defects. Manufacturers also conduct visual inspections for defects such as burrs, broken wires, or irregular mesh patterns. Furthermore, samples from finished rolls are often subjected to accelerated weathering tests, salt spray tests (e.g., ASTM B117), and UV exposure tests to simulate long-term environmental effects and predict service life. The lifespan of a well-manufactured chain link fence, especially those meeting Class 2 or 3 galvanization standards, can exceed 25 years in moderate climates. This rigorous testing regimen, combined with a commitment to continuous improvement, ensures that the product delivered to clients is not merely a fence but a reliable, long-term asset, capable of withstanding diverse environmental stresses and fulfilling its designated security or demarcation function effectively. This comprehensive quality assurance process provides B2B purchasers with the confidence that they are acquiring products built to perform and endure, minimizing long-term operational costs and risks.

Technical Specifications: Comprehensive Parameters for Chain Link Fence Mesh

Selecting the appropriate chain link fence mesh for a project requires a detailed understanding of its technical specifications. These parameters directly influence the fence's performance, durability, and suitability for specific applications. Key specifications include the wire gauge, which dictates the wire's thickness and thus the fence's strength and rigidity; mesh size, determining the size of the diamond opening and influencing visibility and security level; material composition, whether galvanized steel, aluminized steel, or vinyl-coated, each offering distinct advantages in corrosion resistance and aesthetics; and the type of selvage (knuckled or barbed), chosen based on security requirements. For instance, a 9-gauge wire with a 2-inch mesh opening is commonly specified for commercial and industrial applications requiring robust security, while a lighter 11-gauge wire with a 2 1/4-inch mesh might suffice for general property demarcation. Furthermore, the type of coating—Class 1, 2, or 3 galvanization, or specific PVC coating thicknesses—directly impacts the fence's longevity and maintenance profile, with Class 3 galvanization offering significantly extended service life in corrosive environments. It's imperative for procurement managers and engineers to align these technical attributes with project-specific demands, including environmental conditions, required security levels, and budget constraints. This meticulous selection process ensures that the chosen chain link wire fencing system delivers optimal performance and cost-efficiency over its entire operational lifespan, meeting both immediate project goals and long-term strategic objectives.

| Parameter | Description / Common Values | Industry Standard Reference |

|---|---|---|

| Wire Gauge (SWG/AWG) | 6, 9, 11, 11.5, 12.5 gauge (thicker wire = lower gauge number) | ASTM A817, ASTM A392 |

| Mesh Opening Size | 1", 1-3/4", 2", 2-1/4" (diamond pattern) | ASTM A392 |

| Fence Height | 3 ft to 12 ft (common sizes; custom heights available) | ASTM A392 |

| Material & Coating | Galvanized Steel (Class 1, 2, 3), PVC Coated (over Galvanized), Aluminized Steel | ASTM A392, ASTM F668, EN 10244-2 |

| Selvage Type | Knuckled (KK) or Barbed (BB) at both ends | ASTM A392 |

| Roll Length | 50 ft (standard), custom lengths for large projects | Manufacturer Specific |

| Tensile Strength (Wire) | Min. 75,000 PSI (Galvanized), Min. 80,000 PSI (PVC Coated) | ASTM A817 |

Technical Advantages and Diverse Application Scenarios

The inherent technical advantages of chain link fence mesh make it an indispensable asset across a multitude of industries and applications, extending far beyond simple boundary demarcation. Its primary advantage lies in its remarkable durability and corrosion resistance, particularly for galvanized and PVC-coated variants. The galvanized coating acts as a sacrificial layer, protecting the steel core even if the surface is scratched, a property crucial in harsh outdoor environments prevalent in industries like petrochemical and metallurgy, where exposure to corrosive agents or extreme temperatures is common. Furthermore, the open weave of chain link fence provides excellent visibility, which is a critical security feature for surveillance and monitoring purposes, allowing security personnel to easily observe activity on both sides of the fence. This transparency is particularly beneficial in correctional facilities, airports, and power plants. Economically, chain link offers a significantly lower total cost of ownership compared to solid fencing alternatives like concrete walls or ornamental iron, factoring in initial material costs, installation expenses, and minimal maintenance requirements over its extended lifespan. Its flexibility allows for easy installation over uneven terrain, adapting to contours without extensive ground preparation, thus reducing project complexity and costs. In the context of "energy saving," while a fence doesn't directly save energy, its role in securing critical infrastructure like substations or solar farms indirectly contributes by protecting energy assets from theft or vandalism, thereby preventing costly downtime and maintaining energy supply integrity. For specific applications like those in the water supply and drainage sectors, the non-obtrusive nature of the mesh facilitates visual inspection of pipes and pumps, while simultaneously providing robust security against unauthorized access to sensitive equipment.

The versatility of chain link wire fencing manifests in its widespread adoption across diverse sectors, proving its adaptability and performance under varied operational conditions. In the Petrochemical Industry, chain link fences are employed around processing units, storage tanks, and pipelines to control access and secure hazardous zones. The corrosion-resistant properties of galvanized or PVC-coated mesh are paramount here, resisting damage from chemical spills or atmospheric pollutants. For the Metallurgy Industry, where facilities often involve high temperatures and heavy machinery, robust chain link barriers define safety zones, protect equipment, and delineate property lines, offering both physical security and a degree of containment for debris without impeding ventilation. In Water Supply & Drainage Systems, securing reservoirs, pump stations, treatment plants, and distribution networks is vital. Chain link fence provides an effective, visible barrier against tampering and vandalism, safeguarding critical public utilities while allowing for easy visual inspection. Beyond these heavy industries, its applications span numerous other sectors: from Sports Facilities (tennis courts, baseball fields) due to its visibility and ability to contain balls, to Commercial & Industrial Complexes for general perimeter security, and High-Security Environments like military bases and data centers, where it serves as a robust first line of defense, often enhanced with barbed wire or razor wire. Its adaptability also extends to agricultural uses for livestock containment and property division. The ease of integrating chain link systems with security enhancements, such as access control gates, barbed wire extensions, and intrusion detection systems, further solidifies its position as a go-to solution for comprehensive security strategies across all these diverse application scenarios.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

When sourcing chain link fence mesh for large-scale B2B projects, the choice of manufacturer is as critical as the product specifications themselves. A reputable chain link fence company distinguishes itself not merely by competitive pricing, but by adherence to stringent quality standards, robust production capacities, and a proven track record of timely delivery and excellent customer support. Key differentiators include the manufacturer's certifications (e.g., ISO 9001 for quality management, ISO 14001 for environmental management), their testing protocols, and their ability to provide comprehensive documentation, including material certifications and test reports that verify compliance with ASTM, ANSI, or European EN standards. Companies with extensive service years often possess a deeper understanding of varying project requirements and can offer invaluable insights. For example, a manufacturer with 20+ years in the industry might have refined their galvanization process to achieve Class 3 coating consistently, offering superior longevity than competitors. It is advisable to evaluate manufacturers based on their raw material sourcing policies, their in-house quality control labs, and their production line automation, which can significantly impact consistency and defect rates. Furthermore, assessing their logistical capabilities, including packaging, shipping, and handling of international orders, is vital for ensuring smooth project execution. A manufacturer's responsiveness to inquiries and their willingness to provide samples for preliminary evaluation also indicate their commitment to client satisfaction and product quality, building trustworthiness in the business relationship.

Beyond standard offerings, the ability to provide bespoke customization solutions is a hallmark of a premier chain link fence company. B2B projects often present unique challenges that standard off-the-shelf products cannot address, ranging from unusual fence heights and specific mesh opening sizes to unique coating colors for branding or environmental integration. Customization can also extend to specialized wire gauges for extreme security applications, non-standard roll lengths to minimize waste on large perimeters, or the integration of specific accessories like razor wire, barbed wire, or privacy slats during manufacturing. Manufacturers proficient in customization leverage advanced engineering and production flexibility to translate complex client requirements into tangible products. This often involves close collaboration between the client's engineering team and the manufacturer's design and production departments to ensure all technical specifications are met precisely. For instance, a project in a highly corrosive coastal area might require a custom dual-layer PVC coating with enhanced UV inhibitors, a solution a standard supplier might not offer. The value proposition of a manufacturer offering comprehensive customization lies in their capacity to deliver a perfectly tailored solution that not only meets functional requirements but also optimizes cost-efficiency by eliminating the need for on-site modifications or compromises. This level of service enhances project efficiency, reduces potential complications, and ensures that the final chain link fence system is perfectly aligned with the client's strategic objectives and operational demands.

Application Case Studies and Client Success Stories

Real-world application case studies provide tangible evidence of the efficacy and adaptability of chain link fence mesh in diverse operational environments, underscoring its value proposition for B2B stakeholders. Consider a recent project for a major international airport that required a secure perimeter around a new runway expansion. The challenge involved not only achieving robust security against unauthorized access but also maintaining clear visibility for air traffic control and adhering to strict aviation safety regulations concerning wildlife management. By deploying high-tensile 9-gauge galvanized chain link wire fencing with a 2-inch mesh and barbed selvage, combined with specialized post systems and integrated ground-level animal control barriers, the project successfully established a highly effective and compliant security boundary. The transparency of the mesh allowed for uninterrupted visual surveillance and drone detection, while its durability ensured minimal maintenance despite harsh weather conditions. Another compelling example involves a large-scale solar farm in a desert environment. Here, the primary concerns were extreme temperatures, high UV exposure, and the need for cost-effective, rapid deployment across vast, undulating terrain. A PVC-coated chain link fence, specifically designed with enhanced UV stabilizers and installed with flexible footing solutions, proved ideal. The PVC coating provided superior protection against the intense solar radiation and abrasive winds, significantly extending the fence’s lifespan and reducing future replacement costs, leading to considerable long-term savings for the energy company. These cases highlight how a deep understanding of product specifications and application environments, combined with expert installation and strategic planning, allows chain link fence systems to deliver superior performance and meet complex security and operational objectives.

Client feedback and service cases consistently demonstrate the critical role that quality chain fence supplies and expert partnership play in project success. A major logistics hub, facing issues with repeated perimeter breaches and material theft, engaged a specialized chain link fence company. Through a comprehensive site assessment, the company recommended upgrading their existing fencing to a heavier gauge, PVC-coated chain link fence mesh, integrated with a smart security system featuring motion sensors and CCTV cameras. Post-installation, the client reported a 90% reduction in security incidents within the first six months, leading to significant savings from reduced losses and improved operational continuity. The client particularly praised the fence's enhanced resilience to attempted cutting and climbing, attributing it to the specific wire gauge and coating chosen. In another scenario, a municipal water treatment facility required an expedited fence replacement after storm damage. The chosen supplier demonstrated exceptional responsiveness, rapidly fabricating and delivering custom-sized galvanized chain link rolls within a compressed timeline. This efficiency minimized downtime for the critical infrastructure, ensuring uninterrupted public service. The facility managers lauded the product's quality, noting its compliance with local environmental regulations and its robust construction, which provided immediate and long-term security. These testimonials and successful implementations underscore that the value of a chain link fence extends beyond its physical attributes; it encompasses the reliability of the supply chain, the expertise of the provider, and the tangible benefits of enhanced security, operational efficiency, and minimized risks, solidifying trust and establishing long-term collaborative relationships with B2B partners.

Ensuring Trust and Long-Term Value: FAQs, Delivery, and Guarantees

Frequently Asked Questions (FAQs)

-

Q: What is the typical lifespan of a chain link fence mesh?

A: The lifespan of a chain link fence largely depends on the type of coating and environmental conditions. Hot-dip galvanized chain link fences (Class 2 or 3 galvanization) typically last 15-25 years in moderate climates, while PVC-coated fences, especially those applied over a galvanized core, can extend this lifespan to 20-30 years or more, offering superior protection against corrosion and UV degradation, particularly in coastal or industrial settings. Regular inspections and minor maintenance can further prolong its service life, maximizing the return on investment for any chain link wire fencing project.

-

Q: How does wire gauge impact fence security and cost?

A: Wire gauge is inversely proportional to wire thickness; a lower gauge number indicates a thicker, stronger wire. For example, 9-gauge wire is significantly thicker and more robust than 12.5-gauge wire. Thicker wires provide enhanced security by being more resistant to cutting, bending, and impact, making them ideal for high-security applications like industrial facilities or correctional institutions. Consequently, fences made with lower gauge wires are generally more expensive due to higher material costs and greater durability, reflecting a balance between investment and required security level. It's crucial for B2B buyers to assess the specific security threats and operational needs when selecting the optimal wire gauge for their chain link fence mesh, ensuring adequate protection without over-investing.

-

Q: Can chain link fence mesh be customized for specific project needs?

A: Absolutely. Reputable chain link fence company manufacturers offer extensive customization options to meet unique B2B project requirements. This includes variations in wire gauge, mesh opening size, fence height, and roll length. Furthermore, specialized coatings like custom PVC colors for aesthetic integration or specific anti-corrosion treatments for unique environmental challenges can be accommodated. Custom selvage types (knuckled or barbed) and the integration of security features like barbed wire or razor wire can also be specified, ensuring the final product perfectly aligns with security, aesthetic, and functional objectives of the project. This flexibility ensures that clients receive tailored chain fence supplies that integrate seamlessly into complex operational environments, providing optimal performance and long-term value.

Delivery Cycles and Logistics

Understanding delivery cycles is crucial for B2B project planning, particularly for large-volume orders of chain link fence mesh. Standard lead times for common specifications typically range from 2 to 4 weeks, depending on the manufacturer's current production schedule and inventory levels. However, for highly customized orders, specialized coatings, or exceptionally large quantities, lead times may extend to 6-8 weeks or more to accommodate raw material procurement and bespoke manufacturing processes. Efficient manufacturers prioritize clear communication regarding production timelines and provide regular updates on order status. They also offer flexible shipping options, including sea freight for international bulk orders, road transport for domestic deliveries, and expedited services when project timelines are critical. Robust packaging, often involving weather-resistant wraps and secure palletization, is standard to prevent damage during transit, ensuring the chain fence supplies arrive on-site in pristine condition, ready for immediate deployment. This logistical precision is a hallmark of a reliable chain link fence company, minimizing project delays and ensuring seamless integration into construction schedules.

Quality Assurance and Warranty Commitments

A key indicator of a trustworthy chain link fence company is its robust quality assurance and warranty commitments. Premier manufacturers stand behind their chain link fence mesh products with comprehensive warranties that cover manufacturing defects, premature corrosion, and material failure under normal operating conditions. Typical warranty periods for galvanized chain link can range from 10 to 15 years, while high-grade PVC-coated products often come with warranties extending up to 15-20 years, reflecting the superior protective qualities of these coatings. These guarantees are usually supported by a rigorous quality control system that adheres to international standards like ISO 9001, ensuring consistent product quality from raw material inspection to final product testing. Beyond the warranty, a commitment to exceptional customer support is paramount. This includes readily available technical assistance for installation guidance, troubleshooting, and post-sales inquiries. Manufacturers providing dedicated account managers and accessible support channels (phone, email, online portals) demonstrate a long-term partnership approach, ensuring that any issues are resolved promptly and efficiently. This holistic approach to product quality, after-sales support, and transparent guarantees instills confidence and reinforces the long-term value proposition for B2B clients, distinguishing superior chain fence supplies providers in the competitive market.

Authoritative References

- ASTM International. "ASTM A392/A392M – 20 Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric."

- ASTM International. "ASTM F668/F668M – 17 Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric."

- ISO (International Organization for Standardization). "ISO 9001:2015 Quality management systems – Requirements."

- Galvanizers Association. "Corrosion Resistance of Galvanized Steel."

- Fencing Manufacturers Association (FMA). "Chain Link Fence Manufacturers Institute (CLFMI) Product Manual."

-

Metal Products Company Galvanized Cable for SaleNewsAug.06,2025

-

Maintenance of Rock Wall with Wire MeshNewsAug.06,2025

-

Loop Tie Wire Cost Effective OptionsNewsAug.06,2025

-

High Quality Cable Cu Xlpe Swa Pvc SupplyNewsAug.06,2025

-

Durable Hexagonal Mesh Wire ProductsNewsAug.06,2025

-

Baling Wire Direct Reliable ServiceNewsAug.06,2025

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025