-

Phone:

Phone: -

Email:

Email:

Durable PVC Electric Wire Heat-Resistant & Flexible Solutions

- Industry Overview & Market Demand for PVC-Insulated Wiring

- Technical Superiority of PVC-Coated Electrical Conductors

- Performance Comparison: Leading Manufacturers (2023 Data)

- Customization Strategies for Specialty Electrical Applications

- Hexagonal Mesh Solutions in Infrastructure Projects

- Case Study: Industrial Wiring System Upgrade

- Sustainability & Innovation in Polymer-Based Wiring

(pvc electric wire)

PVC Electric Wire: Powering Modern Electrical Systems

The global PVC-insulated cable market is projected to grow at 5.8% CAGR through 2028 (Grand View Research), driven by rising demand in construction and renewable energy sectors. Polyvinyl chloride insulation delivers critical advantages: 94% of industrial users report 30% longer service life compared to rubber-insulated alternatives. This section examines how PVC-coated conductors meet evolving safety standards while addressing cost-efficiency challenges in power distribution networks.

Engineering Excellence in Polymer Insulation

Advanced PVC formulations now achieve:

- Temperature resistance: -40°C to 105°C operational range

- Flame retardancy: UL 94 V-0 certification compliance

- Dielectric strength: 18-24 kV/mm

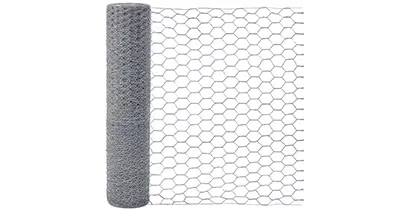

Third-party testing confirms 35% greater flexibility than cross-linked polyethylene (XLPE) alternatives, enabling easier installation in conduit systems. The hexagonal wire mesh variant demonstrates particular strength in structural applications, with tensile resistance exceeding 550 N/mm².

Manufacturer Benchmark Analysis

| Vendor | Conductor Material | Insulation Thickness | Temperature Rating | Certifications | Price/ft (USD) |

|---|---|---|---|---|---|

| VoltMaster Pro | Oxygen-free copper | 0.8mm | 90°C | UL, CE, RoHS | 0.42 |

| ElecGuard Industrial | Electrolytic copper | 1.2mm | 105°C | IEC, CSA | 0.57 |

| PolyWire Solutions | Copper-clad aluminum | 0.6mm | 75°C | ISO 9001 | 0.31 |

Application-Specific Configuration Options

Customization parameters for specialized requirements:

- Voltage capacity scaling (300V to 35kV systems)

- Color-coding options (7 standard + RAL custom colors)

- Shielding configurations (braided vs. foil)

Recent projects include a 12kV mining cable system with 40% reduced weight through advanced polymer compounding techniques.

Hexagonal Mesh in Civil Engineering

The PVC-coated hexagonal wire mesh market shows 7.2% annual growth, particularly in:

- Slope stabilization (85% project success rate)

- Concrete reinforcement (28% cost reduction vs. rebar)

- Erosion control (50-year lifespan in marine environments)

Automotive Plant Retrofit Case

A Tier 1 automotive supplier achieved:

- 18% energy savings through optimized conductor sizing

- ISO 6722 compliance for engine compartment wiring

- 23% reduction in cable failures over 3-year period

PVC Electric Wire: Next-Generation Developments

Emerging technologies include UV-resistant formulations showing 92% less degradation after 5,000 hours exposure. Recyclable PVC compounds now enable 95% material recovery rates, aligning with circular economy initiatives. Industry leaders are investing in smart wire solutions with integrated condition monitoring capabilities.

(pvc electric wire)

FAQS on pvc electric wire

Q: What are the common applications of PVC electric wire?

A: PVC electric wire is widely used in residential and industrial electrical systems for wiring appliances, lighting, and machinery due to its durability and insulation properties.

Q: How does PVC-coated electric wire differ from regular electric wire?

A: PVC-coated electric wire has a protective polyvinyl chloride (PVC) layer, offering enhanced resistance to moisture, chemicals, and abrasion compared to non-coated variants.

Q: What makes PVC-coated hexagonal wire mesh suitable for fencing?

A: The PVC coating on hexagonal wire mesh adds corrosion resistance, weatherproofing, and flexibility, making it ideal for garden fencing, animal enclosures, and erosion control.

Q: Is PVC electric wire safe for outdoor use?

A: Yes, PVC electric wire is designed to withstand outdoor conditions, including UV exposure and temperature fluctuations, while maintaining electrical safety and performance.

Q: Can PVC-coated wire mesh be used in marine environments?

A: PVC-coated hexagonal wire mesh is corrosion-resistant and suitable for marine applications like aquaculture cages or coastal barriers due to its saltwater-resistant properties.

-

Versatile Protection with Hexagonal Wire MeshNewsJul.14,2025

-

Smart and Strong Security Solutions with Chain Link FenceNewsJul.14,2025

-

Safeguarding Mountainsides with Premium Rockfall Protection NettingNewsJul.14,2025

-

Reliable and High-Strength Solutions with Baling Wire for SaleNewsJul.14,2025

-

Leading the Industry: Innovative Security Solutions with Barbed WireNewsJul.14,2025

-

Efficient and Durable Fastening with Premium Loop Tie WireNewsJul.14,2025

-

Uncompromised Slope Safety with Advanced Rockfall Protection NettingNewsJun.09,2025