-

Phone:

Phone: -

Email:

Email:

pvc automotive wire

The Role of PVC in Automotive Wiring

In the automotive industry, wiring plays a crucial role in ensuring the functionality and safety of vehicles. Among various materials available for automotive wiring, Polyvinyl Chloride (PVC) has emerged as a popular choice due to its unique blend of properties that cater to the demands of modern vehicles. This article delves into the significance of PVC in automotive wiring, highlighting its advantages, applications, and challenges.

Understanding PVC

Polyvinyl Chloride, commonly known as PVC, is a synthetic plastic polymer that has become one of the most widely used plastics in the world. PVC can be manufactured in two primary forms rigid and flexible. The flexible variant, often enhanced with plasticizers, is particularly useful in automotive wiring applications. This flexibility allows for easy manipulation and installation in tight spaces, an essential feature as the complexity of automotive electrical systems continues to grow.

Advantages of PVC in Automotive Wiring

1. Durability One of the most significant advantages of PVC is its durability. It is resistant to abrasion, shocks, and chemical exposure, making it suitable for the harsh environments encountered in automotive applications. This resistance extends the lifespan of wiring, reducing the need for frequent replacements.

2. Electrical Insulation PVC offers excellent electrical insulation properties, which is crucial for preventing short circuits and ensuring the safe operation of the vehicle’s electrical systems. This characteristic is vital in high-voltage applications found in electric and hybrid vehicles, where safety is paramount.

3. Flame Resistance With the increasing focus on vehicle safety, flame retardancy has become an essential requirement for automotive materials. PVC can be formulated to meet stringent flame resistance standards, thereby minimizing fire hazards in the event of an electrical failure.

4. Cost-Effectiveness PVC is relatively inexpensive compared to other materials used in automotive wiring. This cost-effectiveness does not compromise performance, making it an attractive option for manufacturers looking to balance quality with budget constraints.

pvc automotive wire

5. Versatility PVC can be easily extruded or molded into various shapes and sizes, making it adaptable for different wiring configurations. This versatility allows automotive engineers to create complex wiring harnesses tailored to the specifications of each vehicle model.

Applications of PVC in the Automotive Sector

PVC is employed in various aspects of automotive wiring, including

- Wiring Harnesses PVC sheathing is commonly used in wiring harnesses, protecting wires from environmental damage and facilitating organization within the vehicle. - Connector Insulation Many automotive connectors are insulated with PVC to ensure a secure and protective environment for electrical connections. - Cable Jacketing PVC is often used as a jacketing material for automotive cables, providing insulation and protection against physical and chemical stressors.

Challenges and Considerations

While PVC offers numerous benefits, there are also challenges associated with its use in automotive wiring. Environmental concerns regarding the production and disposal of PVC have led some manufacturers to explore alternative materials. Additionally, the automotive industry is gradually moving towards more sustainable practices, and this shift may impact the future use of PVC in favor of bio-based or recyclable materials.

Moreover, as automobiles become more technologically advanced, the demand for more sophisticated materials that can support higher temperatures and electrical demands increases. Manufacturers must innovate continuously to keep pace with these evolving requirements while ensuring that wiring components remain reliable and safe.

Conclusion

Polyvinyl Chloride has proven to be a valuable material in the realm of automotive wiring due to its durability, electrical insulation properties, and cost-effectiveness. Its versatility has allowed it to play a vital role in the development of modern vehicles, contributing to the reliability and safety of automotive electrical systems. However, as the industry progresses towards environmentally sustainable practices and advanced technologies, the future of PVC in automotive applications may evolve, prompting a re-evaluation of its role amidst changing materials and greater sustainability demands. Nonetheless, for the foreseeable future, PVC will likely remain a cornerstone in automotive wiring solutions.

-

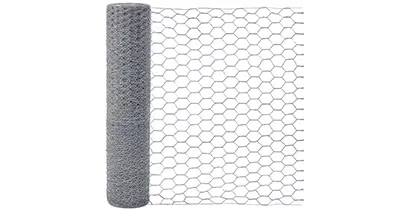

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025