-

Phone:

Phone: -

Email:

Email:

Durable PVC Stay Wire for Reliable Support and Stability in Various Applications

Understanding PVC Stay Wire A Comprehensive Overview

Polyvinyl Chloride, commonly known as PVC, is a versatile thermoplastic that plays a significant role in various industries due to its durability, flexibility, and cost-effectiveness. Among its many applications, one of the most important uses of PVC is in stay wires, which are crucial components in the construction and maintenance of structures such as telephone poles, power lines, and various other frameworks that require reliable support systems. This article delves into the characteristics, benefits, applications, and manufacturing processes of PVC stay wire.

Characteristics of PVC Stay Wire

PVC stay wires are specifically designed for applications that require high tensile strength and low elongation. Made from high-quality PVC material, these wires exhibit excellent resistance against environmental factors such as moisture, UV radiation, and chemical exposure. The remarkable insulation properties of PVC make it a preferable choice for stay wires, ensuring that they can effectively protect metallic components against corrosion and electrical surges.

Moreover, PVC stay wires are lightweight yet extremely robust, making them easy to install and handle during the construction process. Their smooth surface reduces friction and wear, prolonging the lifespan of the wires and minimizing maintenance costs over time.

Benefits of Using PVC Stay Wire

The advantages of PVC stay wires extend beyond their physical properties. One of the primary benefits is their cost-effectiveness. Compared to traditional materials such as steel, PVC stay wires are less expensive and provide a competitive alternative without compromising on quality or performance. This economic advantage is particularly crucial for large-scale construction projects, where budget constraints often play a pivotal role.

In addition to being budget-friendly, PVC stay wires contribute to improved safety features. Their non-conductive nature reduces the risk of electrical hazards, making them ideal for use in areas where electrical lines are present. Furthermore, the flexibility of PVC allows for easier manipulation during installation, ensuring a more secure and stable fit in various applications.

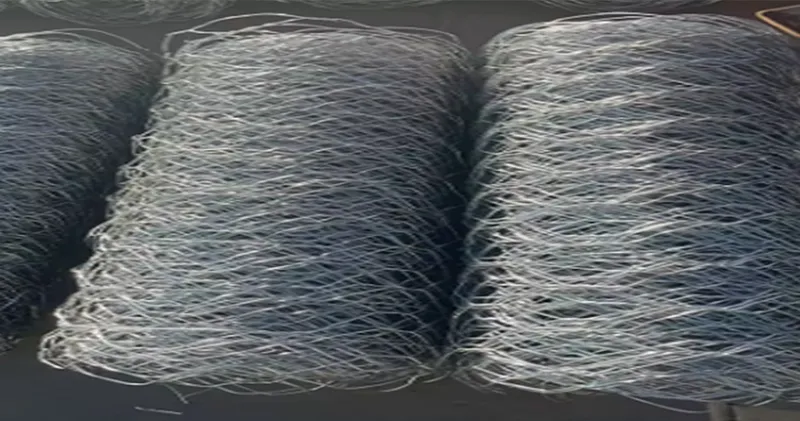

pvc stay wire

Applications of PVC Stay Wire

PVC stay wires have a wide range of applications across different sectors. In the telecommunications industry, they are commonly used to support telephone and internet cables, ensuring that these lines are securely held in place despite environmental stressors such as wind and rain. Similarly, in the electrical sector, PVC stay wires are crucial for maintaining the integrity of overhead power lines, helping to keep them stable and upright.

Furthermore, PVC stay wires find extensive use in the construction of scaffolding and temporary structures, where their lightweight and durable features make them a preferred choice. They are also utilized in agriculture for supporting crops and fencing, demonstrating their versatility in various environments.

Manufacturing Process of PVC Stay Wire

The manufacturing process of PVC stay wire involves several steps that ensure the final product meets the required standards of quality and performance. Initially, the process begins with the selection of high-grade PVC resin, which is then compounded with additives to enhance its properties. This mixture is fed into an extruder, where it is heated and forced through a die to create continuous strands of wire.

Once extruded, the wires undergo cooling and stretching processes to achieve the desired tensile strength and flexibility. After this, they are cut to specific lengths as per customer requirements. Finally, a quality control phase ensures that each wire meets industry standards before packaging and distribution.

Conclusion

In conclusion, PVC stay wire is an essential material in modern construction and infrastructure development. Its unique combination of durability, flexibility, and cost-effectiveness makes it an ideal choice for various applications. As industries continue to evolve and expand, the demand for PVC stay wire is expected to grow, driven by the need for reliable support systems in an ever-changing environment. Understanding the characteristics, benefits, applications, and manufacturing processes of PVC stay wire not only highlights its significance but also underscores the importance of innovation in material science. With its wide range of benefits, PVC stay wire is undoubtedly a critical component in building the future.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025