-

Phone:

Phone: -

Email:

Email:

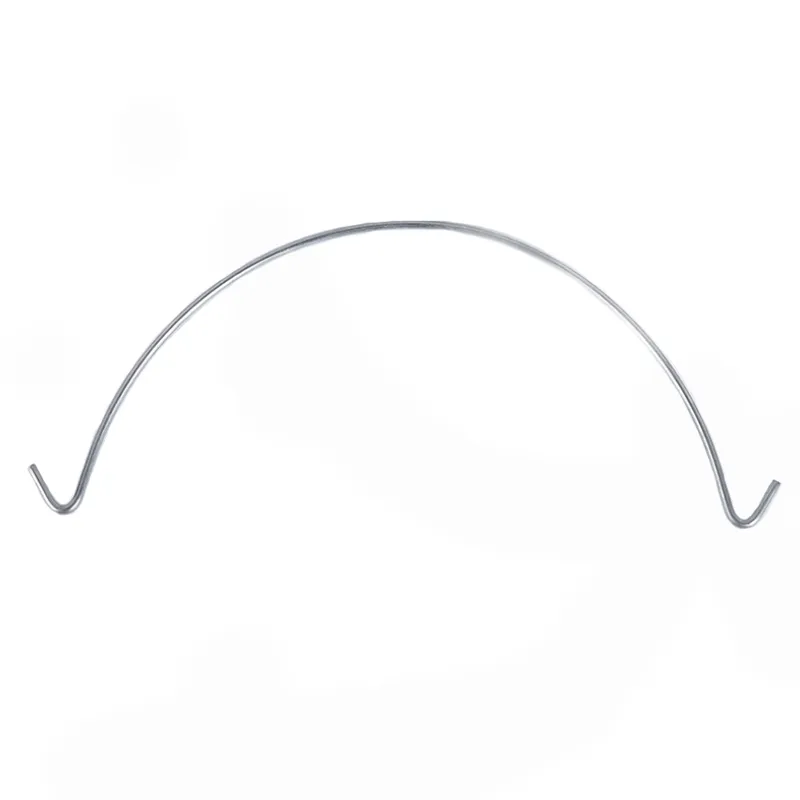

replacement bucket handles

Understanding Replacement Bucket Handles

The term replacement bucket handles may seem straightforward, but it encompasses a variety of applications across different industries, particularly in manufacturing, construction, and everyday household items. A bucket handle is an essential component of a bucket, designed not only for portability but also to provide ease of use when carrying liquids and other materials. When these handles become damaged or broken, the need for replacement is paramount to ensure the bucket's functionality and safety.

Importance of Replacement

Replacement bucket handles are crucial for maintaining the usability of buckets, whether they are used in construction sites, in kitchens, or in gardening. A broken handle can render a bucket nearly useless, leading to spills, accidents, and even injuries. In environments where safety is a priority, such as industrial settings, the importance of promptly replacing faulty handles cannot be overstated. This practice is not merely about aesthetics; it is about maintaining a safe and efficient workflow.

Types of Bucket Handles

There are several types of bucket handles available in the market today. They can be categorized based on material, design, and application. Common materials include plastic, metal, and rubber. Plastic handles are lightweight and resistant to corrosion, making them ideal for household use. Metal handles, often found in heavy-duty buckets, offer enhanced strength and durability, suitable for construction or industrial environments. Rubber handles might be used on buckets that require non-slip features.

The design of the handle also plays a significant role. Ergonomic designs are becoming increasingly popular as they provide comfort and reduce strain, especially when carrying heavy loads. In some cases, handles might be detachable or adjustable, offering versatility depending on the user's requirement.

How to Replace Bucket Handles

replacement bucket handles

Replacing a bucket handle is a simple process that can often be completed with minimal tools. The first step involves assessing the type and model of the bucket to ensure the right replacement handle is chosen. Many manufacturers provide specific replacement parts that are tailored to their products.

After obtaining a suitable replacement handle, the damaged handle must be removed. This process typically involves unscrewing any bolts or detaching clips that hold the handle in place. Once the old handle is removed, the new one can be installed by following the reverse procedure securely attaching it and ensuring it fits snugly.

Benefits of Using Replacement Handles

Using replacement bucket handles has several benefits. It not only extends the life of the bucket, reducing waste, but also saves money in the long run. Rather than purchasing a new bucket, which can be cost-prohibitive, simply replacing a handle allows users to continue using a familiar and functional tool. Additionally, having a stock of replacement handles on hand can prevent downtime in professional settings, allowing tasks to continue uninterrupted.

Moreover, opting for quality replacement handles enhances the overall safety and usability of the buckets being used. Whether in a home, office, or industrial setting, maintaining buckets with quality replacement components ensures that they perform their function effectively and safely.

Conclusion

In conclusion, replacement bucket handles play a vital role in ensuring the continued usability and safety of buckets across various applications. By understanding the types available, the importance of timely replacement, and the benefits, individuals and organizations can make informed decisions that enhance efficiency and safety. Investing time in finding the right replacement handles can ultimately lead to better productivity and a more effective workflow, showcasing the often-overlooked significance of this simple yet essential accessory.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025