-

Phone:

Phone: -

Email:

Email:

replacement bucket handles

Understanding Replacement Bucket Handles A Comprehensive Guide

When it comes to maintaining and optimizing the functionality of various equipment and machinery, the significance of replacement parts cannot be overlooked. Among these components, bucket handles are vital, especially in industries that rely on buckets for material handling, storage, or transport. Whether in construction, gardening, or manufacturing, bucket handles must be durable, reliable, and, when necessary, easily replaceable. This article delves into the importance of replacement bucket handles, the factors to consider when replacing them, and tips for selection and maintenance.

Why Replacement Bucket Handles Matter

Bucket handles might seem like a small component of a larger system, yet their role is critical. They facilitate the easy lifting, pouring, and maneuvering of buckets filled with various materials. Over time, due to repeated use and exposure to environmental factors, these handles can wear out, become damaged, or even break. A malfunctioning handle can pose safety risks, leading to spills, drops, or injuries.

Replacing a bucket handle is not merely about ensuring the bucket remains functional. It also involves enhancing safety and efficiency in operations. In industrial settings, a broken handle can halt processes, leading to delays and economic losses. Thus, investing in high-quality replacement handles is essential.

Factors to Consider When Replacing Bucket Handles

1. Material Quality The material of the replacement handle is paramount. Common materials include plastic, metal, and rubber. Plastic handles are lightweight and resistant to corrosion but may not handle heavy loads. Metal handles, on the other hand, offer durability but can be prone to rust. Rubber handles provide comfort and grip but may wear out faster. Assessing the purpose and environment of the bucket will inform the best material choice.

2. Compatibility Not all bucket handles are universally compatible. It is crucial to ensure that the replacement handle fits the specific bucket design. This includes considering the bucket’s size, shape, and the type of attachment. Proper compatibility will significantly affect the functionality and safety of the bucket.

replacement bucket handles

3. Load Capacity Understanding the weight that the bucket needs to carry is essential. Replacement handles should be rated for the load they will bear. Choosing a handle with insufficient load capacity could lead to failure, resulting in spills and potential accidents.

4. Ease of Installation Some replacement bucket handles require specific tools or skills for installation. Opting for handles that can be easily replaced simplifies maintenance and ensures that downtime is minimized.

Tips for Selection and Maintenance

- Research Brands Look into reputable brands that specialize in bucket handles. Reading reviews and testimonials can help ascertain product quality and durability.

- Check for Warranty A good warranty reflects the manufacturer’s confidence in the product. Additionally, it serves as a safety net should the handle fail prematurely.

- Regular Inspections Before operating any machinery or using a bucket, a quick inspection of the handle can prevent accidents. Look for signs of wear, cracks, or any deformation.

- Proper Storage Store buckets in dry and sheltered conditions to prevent deterioration. Exposure to extreme weather can compromise handle integrity.

In conclusion, replacement bucket handles may be small components, but they play a significant role in ensuring safety and efficiency across various sectors. By understanding the importance of quality materials, compatibility, load capacity, and maintenance, stakeholders can make informed decisions that contribute to smooth operations and user safety. Investing time and resources into finding the right replacement handles can lead to long-term benefits and enhanced productivity.

-

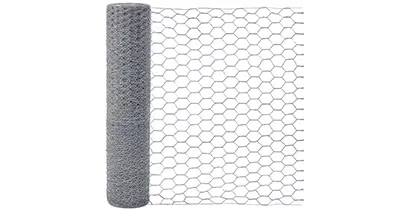

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025