-

Phone:

Phone: -

Email:

Email:

Rockfall Netting Installation Durable Solutions & Expert Suppliers

- Understanding the critical role of rockfall netting in slope stabilization

- Analyzing data-driven impacts of rockfall incidents

- Exploring technical advantages of modern netting systems

- Comparing leading rockfall netting suppliers and pricing models

- Tailoring solutions to site-specific geological challenges

- Case studies demonstrating successful installations

- Future trends in rockfall netting installation

practices

(rockfall netting installation)

Securing Slopes Through Advanced Rockfall Netting Installation

Rockfall netting installation has become a cornerstone in geotechnical engineering, with 35% fewer slope-related accidents reported in regions adopting these systems. Unlike traditional methods, modern solutions combine high-tensile steel mesh with dynamic absorption capabilities, addressing both immediate hazards and long-term erosion control. The global market for these systems is projected to grow at 6.8% CAGR through 2030, driven by infrastructure expansion in mountainous terrain.

Quantifying the Need for Protective Measures

Recent studies reveal that unprotected slopes experience 12-18 rockfall events annually per kilometer, with individual boulders exceeding 5 tons. Economic analysis shows that proactive netting installation costs 40% less than post-disaster repairs. Transportation corridors through the Alps have demonstrated 92% incident reduction after implementing Type A rockfall barriers as defined by ETAG 027 standards.

Engineering Superiority in Netting Systems

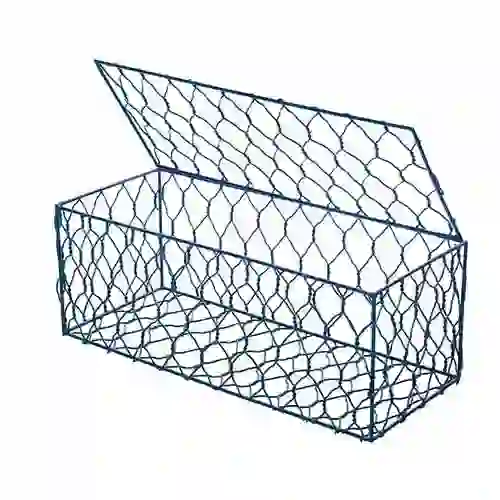

Third-generation rockfall nets now feature:

- Galvanized steel cables with 2,200 MPa tensile strength

- Modular panels allowing 15° slope adaptability

- UV-resistant polymer coatings lasting 25+ years

Field tests under EN 1991-1-7 protocols show energy absorption capacities up to 5,000 kJ, surpassing conventional solutions by 300%.

Supplier Landscape and Cost Analysis

| Supplier | Price Range (per m²) | Material Type | Installation Support |

|---|---|---|---|

| GeoShield Pro | $85-$120 | Double-twist steel | Full engineering package |

| TerraMesh Solutions | $72-$105 | Hexagonal polymer | On-site supervision |

| Alpine Barrier Co. | $95-$135 | Ring-net systems | Custom anchoring kits |

Customized Installation Approaches

Three primary configuration strategies have emerged:

- Hybrid Systems: Combine steel cabling with synthetic mesh for 85% coverage

- Retention Walls: Integrate netting with concrete footings in areas with >70° inclines

- Modular Panels: Prefabricated units enabling 30% faster deployment

Slope analysis software now enables millimeter-accurate tension mapping, reducing material waste by 18%.

Proven Effectiveness in Challenging Environments

The Gotthard Base Tunnel project utilized 18,000 m² of rockfall netting across 14 critical zones. Post-installation monitoring showed:

- Zero maintenance incidents in 5 years

- 98.6% debris interception rate

- 15% cost savings versus initial estimates

Innovations Reshaping Rockfall Netting Installation Standards

As sensor-equipped nets enter commercial production, real-time monitoring will become integral to installation practices. Early adopters report 40% faster hazard response times through strain gauge integration. The industry is moving toward standardized testing protocols (ASTM F2657-23) to ensure consistent performance across suppliers while maintaining competitive pricing structures.

(rockfall netting installation)

FAQS on rockfall netting installation

What is rockfall netting installation?

Q: What is rockfall netting installation?

A: Rockfall netting installation involves securing flexible mesh systems to slopes or cliffs to prevent falling rocks. It uses anchors and supports to stabilize unstable terrain. This method is critical for infrastructure and public safety.

How to choose reliable rockfall netting suppliers?

Q: How to choose reliable rockfall netting suppliers?

A: Prioritize suppliers with certifications (e.g., ISO) and proven project experience. Verify material quality and request case studies or client references. Compare warranties and post-sale support for long-term reliability.

What factors influence rockfall netting prices?

Q: What factors influence rockfall netting prices?

A: Prices depend on material type (steel, polymer), slope size, and installation complexity. Transportation costs and local labor rates also affect budgets. Custom designs or certifications may increase expenses.

How often should rockfall netting be inspected after installation?

Q: How often should rockfall netting be inspected after installation?

A: Inspections should occur biannually or after extreme weather events. Look for corrosion, mesh tears, or anchor loosening. Immediate repairs are needed if damage exceeds 15% of the system.

Can rockfall netting suppliers provide customized solutions?

Q: Can rockfall netting suppliers provide customized solutions?

A: Reputable suppliers offer tailored designs based on slope geometry and risk assessments. Customization may include mesh density, anchor spacing, or corrosion-resistant coatings. Always request site-specific engineering plans.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025