-

Phone:

Phone: -

Email:

Email:

Jan . 14, 2025 10:36

Back to list

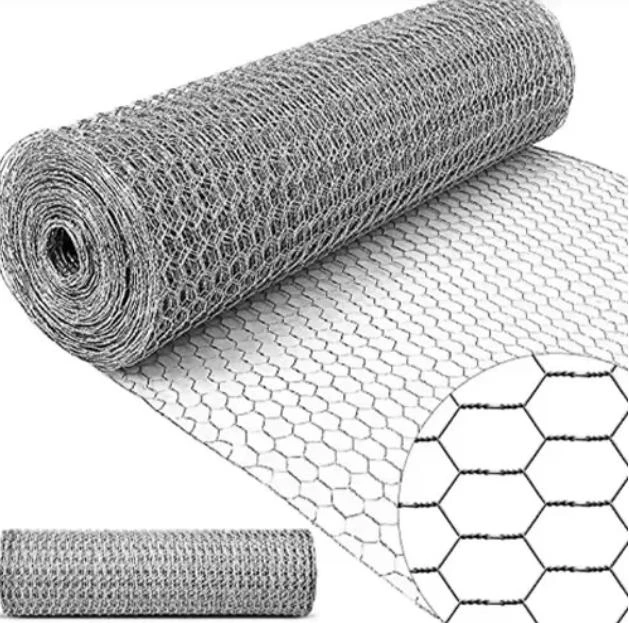

rock netting

Rock netting, a critical component in geotechnical engineering, has become indispensable for ensuring safety and stability in various construction and natural settings. As an advanced protective solution, rock netting is designed to prevent rocks and debris from falling onto roadways, railways, and inhabited areas, thereby safeguarding human lives and infrastructure. This article delves into the practical application, expertise needed, and authoritative insights surrounding the use of rock netting.

When it comes to authoritative application, the deployment of rock netting is often overseen by industry-leading geotechnical firms. These companies have established themselves as pioneers through years of research, development, and successful project completions. Their authority in the field is further underpinned by continuous training programs that keep their teams updated on the latest innovations in rock stability technologies. Trustworthiness in rock netting solutions is paramount, as these systems play a vital role in protecting areas prone to rockslides. To ensure reliability, products must adhere to stringent international standards, such as those set by the International Organization for Standardization (ISO) and other relevant bodies. Regular inspections and maintenance are also critical for maintaining the integrity of the netting over time. Third-party verification by independent bodies can provide an additional layer of trust, confirming the effectiveness and compliance of the rock netting system. In conclusion, rock netting is not just a barrier; it's a complex engineered system that combines experience, expertise, and authoritative knowledge to deliver trustworthy protection against geological hazards. Moreover, as technology evolves, so too does the efficacy of rock netting, with innovations continually enhancing its performance and ease of installation. For stakeholders in industries such as transportation, construction, and mining, understanding these aspects of rock netting is crucial. By selecting a solution that incorporates the latest advancements and adheres to the highest standards, these stakeholders ensure the safety and longevity of their projects and the wellbeing of those in the vicinity.

When it comes to authoritative application, the deployment of rock netting is often overseen by industry-leading geotechnical firms. These companies have established themselves as pioneers through years of research, development, and successful project completions. Their authority in the field is further underpinned by continuous training programs that keep their teams updated on the latest innovations in rock stability technologies. Trustworthiness in rock netting solutions is paramount, as these systems play a vital role in protecting areas prone to rockslides. To ensure reliability, products must adhere to stringent international standards, such as those set by the International Organization for Standardization (ISO) and other relevant bodies. Regular inspections and maintenance are also critical for maintaining the integrity of the netting over time. Third-party verification by independent bodies can provide an additional layer of trust, confirming the effectiveness and compliance of the rock netting system. In conclusion, rock netting is not just a barrier; it's a complex engineered system that combines experience, expertise, and authoritative knowledge to deliver trustworthy protection against geological hazards. Moreover, as technology evolves, so too does the efficacy of rock netting, with innovations continually enhancing its performance and ease of installation. For stakeholders in industries such as transportation, construction, and mining, understanding these aspects of rock netting is crucial. By selecting a solution that incorporates the latest advancements and adheres to the highest standards, these stakeholders ensure the safety and longevity of their projects and the wellbeing of those in the vicinity.

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS