-

Phone:

Phone: -

Email:

Email:

Jan . 30, 2025 05:02

Back to list

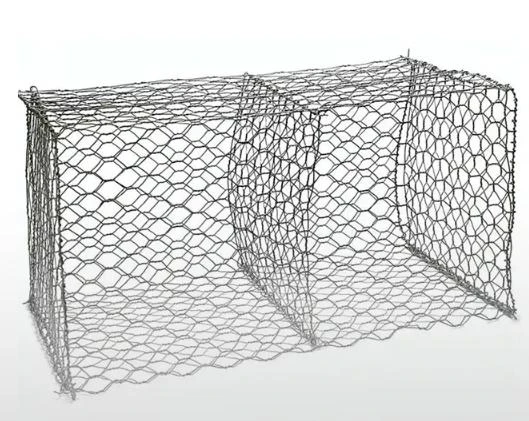

Gabion fence

Determining the cost of rock netting involves understanding various elements crucial to ensuring stability and safety in areas susceptible to rockfalls and landslips. Rock netting, a vital solution in construction and mining industries, involves covering rock faces with protective mesh to prevent loose rocks from detaching and causing damage or injury. The expenses associated with the installation and maintenance of rock netting systems can vary significantly based on multiple factors.

Moreover, the scale and scope of the project determine whether economies of scale might be applied. Larger projects can sometimes reduce per-square-meter costs due to bulk purchasing of materials and labor efficiencies. However, projects on a smaller scale might not benefit from such economies, making per-square-meter costs relatively higher. Calculating the exact footprint of the area requiring netting and accurately estimating the material needed is crucial for budgeting effectively. Maintenance and inspection are ongoing costs that must be factored into the overall expenditure. While the initial investment in quality materials can reduce these future costs, regular inspections are essential to ensure the system's integrity and performance. Damages or wear incurred due to environmental factors or rock movement necessitate timely repairs or replacements to uphold safety. Developing an inspection and maintenance schedule from the outset can help manage these ongoing expenses more predictably. Installation labor, often requiring skilled professionals trained in working at heights and on unstable surfaces, can significantly impact rock netting costs. Ensuring that the workforce is not only well-trained but also equipped with the necessary safety gear and tools is paramount. It is vital to hire reputable contractors with proven experience in similar projects to avoid cutting corners, which could lead to increased risks and potential additional costs due to mistakes or accidents. Lastly, regulatory compliance dictates specific standards and guidelines that must be adhered to, potentially influencing costs. Ensuring that all components meet local engineering standards and safety requirements can affect both the selection of materials and the installation process. Working with regulatory bodies from the initial stages can facilitate a smoother process and potentially avoid costly reworks or fines later. In conclusion, understanding the comprehensive aspects affecting rock netting costs from location and geological conditions to material choice and regulatory compliance is critical for accurate budgeting and efficient project execution. Leveraging professional expertise and conducting a thorough analysis of each project's unique requirements help ensure a successful outcome that balances cost, safety, and durability.

Moreover, the scale and scope of the project determine whether economies of scale might be applied. Larger projects can sometimes reduce per-square-meter costs due to bulk purchasing of materials and labor efficiencies. However, projects on a smaller scale might not benefit from such economies, making per-square-meter costs relatively higher. Calculating the exact footprint of the area requiring netting and accurately estimating the material needed is crucial for budgeting effectively. Maintenance and inspection are ongoing costs that must be factored into the overall expenditure. While the initial investment in quality materials can reduce these future costs, regular inspections are essential to ensure the system's integrity and performance. Damages or wear incurred due to environmental factors or rock movement necessitate timely repairs or replacements to uphold safety. Developing an inspection and maintenance schedule from the outset can help manage these ongoing expenses more predictably. Installation labor, often requiring skilled professionals trained in working at heights and on unstable surfaces, can significantly impact rock netting costs. Ensuring that the workforce is not only well-trained but also equipped with the necessary safety gear and tools is paramount. It is vital to hire reputable contractors with proven experience in similar projects to avoid cutting corners, which could lead to increased risks and potential additional costs due to mistakes or accidents. Lastly, regulatory compliance dictates specific standards and guidelines that must be adhered to, potentially influencing costs. Ensuring that all components meet local engineering standards and safety requirements can affect both the selection of materials and the installation process. Working with regulatory bodies from the initial stages can facilitate a smoother process and potentially avoid costly reworks or fines later. In conclusion, understanding the comprehensive aspects affecting rock netting costs from location and geological conditions to material choice and regulatory compliance is critical for accurate budgeting and efficient project execution. Leveraging professional expertise and conducting a thorough analysis of each project's unique requirements help ensure a successful outcome that balances cost, safety, and durability.

Next:

Latest news

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025

Related PRODUCTS