-

Phone:

Phone: -

Email:

Email:

steel rebar tie wire

The Importance of Steel Rebar Tie Wire in Construction

In the construction industry, the integrity and durability of structures hinge significantly on meticulous practices in reinforcement. One of the unsung heroes of this process is steel rebar tie wire, a crucial element that ensures the stability and longevity of concrete structures. This article delves into the functions, materials, and benefits of steel rebar tie wire, highlighting its critical role in construction projects.

Steel rebar, short for reinforcement bar, provides necessary tensile strength to concrete, which is inherently weak in tension. While rebar acts as the backbone of concrete infrastructure, tie wire serves an equally important function it binds rebar together, maintaining the structural geometry during the concrete pouring process. This is essential because any misalignment can weaken the structure, leading to potential failure.

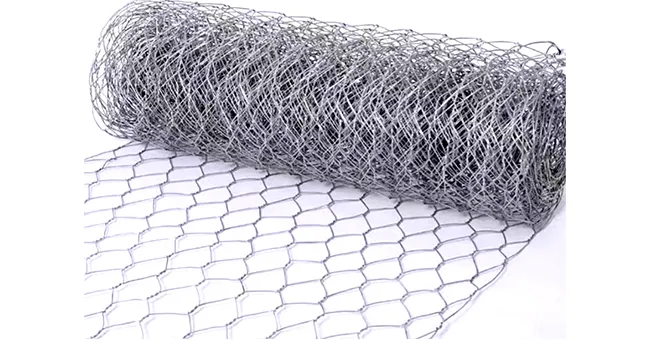

Tie wire is commonly made from high-quality steel, ensuring strength and resilience. Various types of tie wire exist in the market, with different gauges (thicknesses) to suit specific needs. The most prevalent types are annealed and galvanized wire. Annealed wire is softer and more pliable, making it ideal for binding rebar together effortlessly. On the other hand, galvanized wire has a protective zinc coating, significantly enhancing its resistance to corrosion, making it a favored choice for outdoor or moisture-prone projects.

steel rebar tie wire

The application of steel rebar tie wire is straightforward but requires skilled hands to ensure effective binding. Typically, workers will cut the wire to the desired length and tie it around the intersecting rebar. This process creates a secure framework that keeps the rebar in place, preventing any movement during the concrete flow. The importance of this alignment cannot be understated, as improper wiring can lead to weak points within the structure, ultimately affecting its performance and safety.

Beyond its practical functions, rebar tie wire also has implications for building codes and regulations. Many jurisdictions mandate strict adherence to reinforcement standards, and the use of high-quality tie wire is often necessary to meet these criteria. By utilizing appropriate tie wire, contractors demonstrate their commitment to structural integrity, meeting or exceeding industry standards.

Moreover, the cost-effectiveness of steel rebar tie wire makes it an attractive option for construction projects of all scales. Generally sold in coils, it is both accessible and affordable, allowing builders to remain within budget while ensuring high safety and quality standards. Proper use of tie wire not only enhances safety but can also contribute to efficiency in the construction timeline, as a well-structured rebar framework simplifies the pouring process.

In conclusion, steel rebar tie wire plays an indispensable role in construction. It acts as the critical connective tissue in the relationship between rebar and concrete, ensuring that structures remain sound and reliable. For builders and contractors, investing in high-quality tie wire is a step towards achieving robust and long-lasting buildings. By understanding the importance of this often-overlooked material, construction professionals can further their commitment to quality and safety, ultimately supporting the longevity of their projects.

-

Wire Mesh for Every Need: A Practical SolutionNewsJul.25,2025

-

Steel Fences: Durable, Secure, and Stylish OptionsNewsJul.25,2025

-

Roll Top Fencing: A Smart Solution for Safety and SecurityNewsJul.25,2025

-

Cattle Farm Fencing Solutions for Maximum SecurityNewsJul.25,2025

-

Affordable Iron Binding Wire SolutionsNewsJul.25,2025

-

Affordable Galvanized Wire SolutionsNewsJul.25,2025

-

Wire Hanger Recycling IdeasNewsJul.25,2025